-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

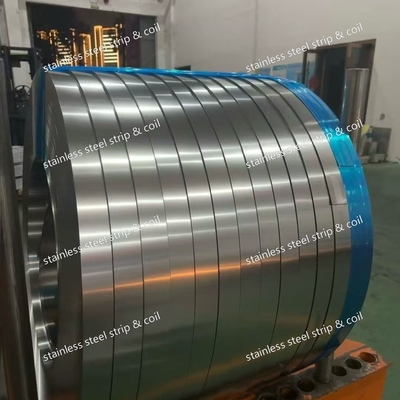

Stainless Steel Strips 301 304 for Springs in Various Tempers

| Place of Origin | China |

|---|---|

| Brand Name | TISCO |

| Certification | ISO |

| Model Number | 300 Series / 400 Series |

| Minimum Order Quantity | 2 Ton |

| Price | 2000-3000 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products | Stainless Steel Strip | Thickness | 0.5-8.0mm |

|---|---|---|---|

| Width | Within 1500mm | MOQ | 500 Kgs |

| Grade | 200 Series 300 Series 300 Series | Surface | BA 2B NO.4 HL 8K NO.1 |

| Standard | ASTM EN GB JIS | Packing | Wooden Frame And Water Proof Paper |

| Highlight | 301 stainless steel strips for springs,304 stainless steel temper strips,stainless steel strips various tempers |

||

| Products | stainless steel strip |

|---|---|

| Thickness | 0.5-8.0mm |

| Width | within 1500mm |

| MOQ | 500 kgs |

| Grade | 200 series 300 series 300 series |

| Surface | BA 2B NO.4 HL 8K NO.1 |

| Standard | ASTM EN GB JIS |

| Packing | wooden frame and water proof paper |

Specialized in manufacturing high-performance stainless steel strips for spring applications, our products feature Alloy 301 and 304 in various temper conditions: Soft Anneal (SA), 1/4 Hard (1/4H), 1/2 Hard (1/2H), 3/4 Hard (3/4H), and Full Hard (FH). Engineered to meet the strict demands of spring fabrication, these strips offer exceptional elasticity, fatigue resistance, and dimensional stability.

Alloy 301 is renowned for its high tensile strength and formability in spring applications, while 304 provides superior corrosion resistance for environments requiring durability. The controlled annealing and cold-working processes ensure precise hardness levels, making them ideal for compression springs, torsion springs, extension springs, and precision spring components across industries such as automotive, electronics, aerospace, and medical devices.

| Parameter | Details |

|---|---|

| Material Grades | 301 (UNS S30100), 304 (UNS S30400) (AISI/ASME standards) |

| Temper Conditions | Soft Anneal (SA), 1/4 Hard (1/4H), 1/2 Hard (1/2H), 3/4 Hard (3/4H), Full Hard (FH) |

| Thickness | 0.1mm - 2.0mm (Tolerance: ±0.01mm for thickness ≤1mm; ±0.02mm for >1mm) |

| Width | 10mm - 610mm (Slit cutting tolerance: ±0.1mm for width ≤200mm; ±0.2mm for >200mm) |

| Hardness (HV) | SA: 140-200 1/4H: 250-320 1/2H: 320-380 3/4H: 380-450 FH: 450-550 |

| Tensile Strength (MPa) | 301: SA: 520-750 1/4H: 750-1000 1/2H: 1000-1300 3/4H: 1300-1500 FH: 1500-1700 304: SA: 550-800 1/2H: 850-1100 FH: 1100-1350 |

| Elongation at Break | SA: ≥35% (301), ≥40% (304) FH: ≥10% (301), ≥15% (304) |

| Surface Finish | 2B (Standard), BA (Bright Annealed), No.4 Polish, Anti-Fingerprint Coating |

| Edge Quality | Burr-free, smooth edge (Ra ≤1.6μm) with precision slitting technology |

- Coil Weight: 50kg - 1500kg per coil (Customizable for spring wire applications)

- Inner Diameter: 305mm (Narrow strips) / 508mm (Wide strips)

- Outer Diameter: Up to 1200mm (Subject to thickness and temper)

- Straight Strips Length: 500mm - 6000mm (Precision-cut for spring blanks)

| Grade | Temper | Key Properties | Typical Spring Applications |

|---|---|---|---|

| 301 | SA | High ductility for forming complex spring shapes | Pre-forming of compression springs |

| 301 | 1/4H-3/4H | Balanced elasticity and formability | Torsion springs, automotive valve springs |

| 301 | FH | Maximum tensile strength and spring resilience | Heavy-duty industrial springs, aerospace springs |

| 304 | SA-1/2H | Corrosion resistance with moderate elasticity | Medical device springs, marine-grade springs |

| 304 | FH | High-strength corrosion resistance | Springs in chemical environments or food processing |

- Precision Temper Control: Consistent hardness across the strip width and length ensures uniform spring performance. Custom temper grades available to match specific spring design requirements.

- Superior Spring Properties: High elastic limit and fatigue resistance (≥1 million cycles under standard load for 301 FH). Low relaxation rate under prolonged stress.

- Dimensional Accuracy: Tight thickness and width tolerances reduce spring manufacturing waste. Flatness tolerance: ≤3mm/m for strips ≥0.5mm thickness.

- Surface Quality: Smooth, defect-free surfaces minimize stress concentrations during spring coiling. Optional anti-fingerprint coatings available.

- Formability: Soft Anneal and 1/4H tempers allow intricate coiling and shaping without cracking. Full Hard temper retains shape after forming.

- Material Standards: ASTM A666, ASTM A313, JIS G4313, EN 10270-3

- Certifications: Mill Test Certificates (MTC) including chemical composition, mechanical properties, and temper compliance. Optional third-party inspection reports available.

- Anti-Rust Protection: Wrapped with VCI paper or PE film. High-temper strips have foam-protected edges.

- Secure Packaging: Coils ≤500kg in reinforced cardboard boxes; >500kg palletized on wooden crates with steel strapping.

- Labeling: Clear identification of grade, temper, thickness, width, and heat number. Custom labels available.

- Quality Assurance: 100% inspection for hardness, dimensional accuracy, and surface defects. Spring performance testing available.

- Warranty: 12-month warranty against temper inconsistency, surface flaws, or dimensional non-conformance.

- Technical Support: Spring design consultation and processing guidance available.

- Return & Replacement: Full refund or free replacement for non-conforming products confirmed by joint inspection.

For custom spring strip requirements or to request samples, contact our technical sales team with your spring design specifications (e.g., wire diameter, spring type, load requirements). We specialize in delivering tailored solutions that enhance spring reliability and performance in the most demanding applications.