-

Raian IonescuQualidade material muito boa. nós temos cooperar mais de 10 anos. Trocam tipos dos lotes do material de aço. Toda a qualidade material boa. Eles dever para toda a qualidade material. Nós estamos aplanando para continuar a cooperar no futuro com eles

Raian IonescuQualidade material muito boa. nós temos cooperar mais de 10 anos. Trocam tipos dos lotes do material de aço. Toda a qualidade material boa. Eles dever para toda a qualidade material. Nós estamos aplanando para continuar a cooperar no futuro com eles

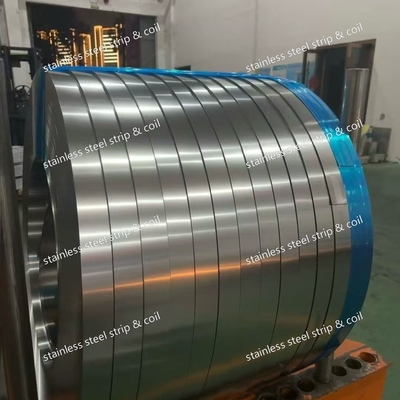

Fitas de Aço Inoxidável 301 304 para Molas em Diversas Têmperas

| Lugar de origem | China |

|---|---|

| Marca | TISCO |

| Certificação | ISO |

| Número do modelo | Série 300 / Série 400 |

| Quantidade de ordem mínima | 2 toneladas |

| Preço | 2000-3000 USD/Ton |

| Detalhes da embalagem | Embalagem padrão para exportação |

| Tempo de entrega | 5 - 12 dias em função da quantidade |

| Termos de pagamento | L/C, T/T, Western Union |

| Habilidade da fonte | 20 toneladas por semana |

Contacte-me para amostras grátis e vales.

whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Se você tem algum interesse, nós fornecemos a ajuda online de 24 horas.

x| Produtos | Faixa de aço inoxidável | Espessura | 0.5-8.0mm |

|---|---|---|---|

| Largura | em 1500 milímetro | MOQ | 500 kg |

| Grau | 200 séries 300 séries 300 séries | Superfície | BA 2B NO.4 HL 8K NO.1 |

| Padrão | ASTM EN GB JIS | embalagem | Quadro de madeira e papel à prova de água |

| Destacar | Fitas de aço inoxidável 301 para molas,Fitas de têmpera de aço inoxidável 304,Fitas de aço inoxidável diversas têmperas |

||

| Produtos | tira de aço inoxidável |

|---|---|

| Espessura | 0.5-8.0mm |

| Largura | dentro de 1500mm |

| MOQ | 500 kgs |

| Grau | Série 200 Série 300 Série 300 Série |

| Superfície | BA 2B NO.4 HL 8K NO.1 |

| Padrão | ASTM EN GB JIS |

| Embalagem | estrutura de madeira e papel à prova d'água |

Especializados na fabricação de tiras de aço inoxidável de alto desempenho para aplicações em molas, nossos produtos apresentam as ligas 301 e 304 em várias condições de têmpera: Recozido Macio (SA), 1/4 Duro (1/4H), 1/2 Duro (1/2H), 3/4 Duro (3/4H) e Duro Total (FH). Projetadas para atender às exigências rigorosas da fabricação de molas, essas tiras oferecem elasticidade excepcional, resistência à fadiga e estabilidade dimensional.

A liga 301 é renomada por sua alta resistência à tração e conformabilidade em aplicações de molas, enquanto a 304 oferece resistência superior à corrosão para ambientes que exigem durabilidade. Os processos controlados de recozimento e trabalho a frio garantem níveis precisos de dureza, tornando-as ideais para molas de compressão, molas de torção, molas de extensão e componentes de molas de precisão em setores como automotivo, eletrônico, aeroespacial e dispositivos médicos.

| Parâmetro | Detalhes |

|---|---|

| Graus de Material | 301 (UNS S30100), 304 (UNS S30400) (padrões AISI/ASME) |

| Condições de Têmpera | Recozido Macio (SA), 1/4 Duro (1/4H), 1/2 Duro (1/2H), 3/4 Duro (3/4H), Duro Total (FH) |

| Espessura | 0.1mm - 2.0mm (Tolerância: ±0.01mm para espessura ≤1mm; ±0.02mm para >1mm) |

| Largura | 10mm - 610mm (Tolerância de corte por fenda: ±0.1mm para largura ≤200mm; ±0.2mm para >200mm) |

| Dureza (HV) | SA: 140-200 1/4H: 250-320 1/2H: 320-380 3/4H: 380-450 FH: 450-550 |

| Resistência à Tração (MPa) | 301: SA: 520-750 1/4H: 750-1000 1/2H: 1000-1300 3/4H: 1300-1500 FH: 1500-1700 304: SA: 550-800 1/2H: 850-1100 FH: 1100-1350 |

| Alongamento na Ruptura | SA: ≥35% (301), ≥40% (304) FH: ≥10% (301), ≥15% (304) |

| Acabamento da Superfície | 2B (Padrão), BA (Recozido Brilhante), Polimento No.4, Revestimento Anti-Impressão Digital |

| Qualidade da Borda | Sem rebarbas, borda lisa (Ra ≤1.6μm) com tecnologia de corte por fenda de precisão |

- Peso da Bobina: 50kg - 1500kg por bobina (Personalizável para aplicações de arame de mola)

- Diâmetro Interno: 305mm (Tiras estreitas) / 508mm (Tiras largas)

- Diâmetro Externo: Até 1200mm (Sujeito à espessura e têmpera)

- Comprimento das Tiras Retas: 500mm - 6000mm (Corte de precisão para peças de mola)

| Grau | Têmpera | Propriedades Chave | Aplicações Típicas de Molas |

|---|---|---|---|

| 301 | SA | Alta ductilidade para formar formatos de mola complexos | Pré-formação de molas de compressão |

| 301 | 1/4H-3/4H | Elasticidade e conformabilidade equilibradas | Molas de torção, molas de válvulas automotivas |

| 301 | FH | Resistência à tração máxima e resiliência da mola | Molas industriais pesadas, molas aeroespaciais |

| 304 | SA-1/2H | Resistência à corrosão com elasticidade moderada | Molas de dispositivos médicos, molas de grau marinho |

| 304 | FH | Resistência à corrosão de alta resistência | Molas em ambientes químicos ou processamento de alimentos |

- Controle de Têmpera de Precisão: Dureza consistente em toda a largura e comprimento da tira garante desempenho uniforme da mola. Graus de têmpera personalizados disponíveis para corresponder aos requisitos específicos de projeto da mola.

- Propriedades Superiores da Mola: Limite elástico alto e resistência à fadiga (≥1 milhão de ciclos sob carga padrão para 301 FH). Baixa taxa de relaxamento sob estresse prolongado.

- Precisão Dimensional: Tolerâncias apertadas de espessura e largura reduzem o desperdício na fabricação de molas. Tolerância de planicidade: ≤3mm/m para tiras ≥0.5mm de espessura.

- Qualidade da Superfície: Superfícies lisas e sem defeitos minimizam as concentrações de tensão durante o enrolamento da mola. Revestimentos anti-impressão digital opcionais disponíveis.

- Conformabilidade: Temperas Recozido Macio e 1/4H permitem enrolamento e modelagem intrincados sem rachaduras. A têmpera Duro Total mantém a forma após a formação.

- Padrões de Material: ASTM A666, ASTM A313, JIS G4313, EN 10270-3

- Certificações: Certificados de Teste de Fábrica (MTC), incluindo composição química, propriedades mecânicas e conformidade com a têmpera. Relatórios de inspeção de terceiros opcionais disponíveis.

- Proteção Anti-Ferrugem: Embalado com papel VCI ou filme PE. As tiras de alta têmpera têm bordas protegidas por espuma.

- Embalagem Segura: Bobinas ≤500kg em caixas de papelão reforçadas; >500kg paletizadas em caixas de madeira com cintas de aço.

- Rotulagem: Identificação clara do grau, têmpera, espessura, largura e número do lote. Rótulos personalizados disponíveis.

- Garantia de Qualidade: Inspeção de 100% para dureza, precisão dimensional e defeitos de superfície. Testes de desempenho da mola disponíveis.

- Garantia: Garantia de 12 meses contra inconsistência de têmpera, falhas de superfície ou não conformidade dimensional.

- Suporte Técnico: Consulta de projeto de mola e orientação de processamento disponíveis.

- Devolução e Substituição: Reembolso total ou substituição gratuita para produtos não conformes confirmados por inspeção conjunta.

Para requisitos de tiras de mola personalizadas ou para solicitar amostras, entre em contato com nossa equipe de vendas técnicas com suas especificações de projeto de mola (por exemplo, diâmetro do fio, tipo de mola, requisitos de carga). Somos especializados em fornecer soluções personalizadas que aprimoram a confiabilidade e o desempenho da mola nas aplicações mais exigentes.