-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Grade 926 Super Austenitic Stainless Steel Strip UNS N08926 for Marine Applications

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products | Stainless Steel Strip | Thickness | 0.5-8.0mm |

|---|---|---|---|

| Width | Within 1500mm | MOQ | 500 Kgs |

| Grade | 200 Series 300 Series 300 Series | Surface | BA 2B NO.4 HL 8K NO.1 |

| Standard | ASTM EN GB JIS | Packing | Wooden Frame And Water Proof Paper |

| Highlight | Super Austenitic Stainless Steel Strip,926 Super Austenitic Stainless Steel Strip |

||

| Attribute | Value |

|---|---|

| Products | stainless steel strip |

| Thickness | 0.5-8.0mm |

| Width | within 1500mm |

| MOQ | 500 kgs |

| Grade | 200 series 300 series 300 series |

| Surface | BA 2B NO.4 HL 8K NO.1 |

| Standard | ASTM EN GB JIS |

| Packing | wooden frame and water proof paper |

Grade 926 Super Austenitic Stainless Steel Strip UNS N08926 Standard SS Strip

| Product Name | Stainless Steel Strips |

|---|---|

| Length | As required |

| Width | 3mm-1219mm or as required |

| Thickness | 0.15 - 3.0mm or as required |

| Standard | AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc. |

| Technique | Hot rolled / cold rolled |

| Surface Treatment | 2B or according to customer requirement |

| Thickness tolerance | ±0.01mm |

| Material | 201, 202, 301, 302, 303, 304, 304L, 304H, 310S, 316, 316L, 317L, 321,310S 309S, 410, 410S,420, 430, 431,434, 440A,904L,2205,2507,926 |

| Application | It is widely used in high temperature applications, medical devices, building materials, chemistry, food industry, agriculture, ship components.It also applies to food, beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, and screen. |

| MOQ | 1tons.We also can accept sample order. |

| Shipment time | Within 15-20 workdays after receiving deposit or L/C |

| Export packing | Waterproof paper, and steel strip packed.Standard Export Seaworthy Package.Suit for all kinds of transport,or as required |

| Capacity | 250,000 tons/year |

Alloy 926 is a super-austenitic stainless steel enhanced with high molybdenum (6.0-7.0%), nitrogen (0.15-0.25%), and nickel (24-26%). Designed for extreme corrosive environments, it bridges the gap between standard austenitic steels (e.g., 316L) and high-cost nickel alloys. Its key features include:

- Exceptional corrosion resistance in chloride-rich media (e.g., seawater, acids)

- High strength and ductility due to nitrogen strengthening

- Applications span marine engineering, chemical processing, and pollution control systems

| Element | Composition (%) | Role |

|---|---|---|

| Ni | 24.0-26.0 | Stabilizes austenite; boosts acid resistance |

| Cr | 19.0-21.0 | Forms passive oxide layer |

| Mo | 6.0-7.0 | Enhances pitting/crevice corrosion resistance |

| N | 0.15-0.25 | Increases strength; improves localized corrosion resistance |

| Cu | 0.5-1.5 | Resists sulfuric acid |

| Fe | Balance | Base material |

Minor elements: C ≤0.02%, Mn ≤2.0%, Si ≤0.5%

| Property | Value |

|---|---|

| Density | 8.1 g/cm³ |

| Melting Point | 1320-1390 °C |

| Tensile Strength (Rm) | ≥650 MPa |

| Yield Strength (RP0.2) | ≥295 MPa |

| Elongation (A5%) | ≥35% |

| Hardness (RB) | ≤86 |

Data at room temperature (after solution annealing)

| Environment | Performance |

|---|---|

| Seawater/Chlorides | Resists pitting/crevice corrosion (PREN >40) |

| Acids | Excellent in H2SO4, H3PO4, organic acids |

| Stress Corrosion Cracking (SCC) | Resists Cl--induced SCC |

Validated in FGD systems (Cl- 10,000-70,000 ppm, 50-68°C)

Alloy 926 strip complies with global standards for chemical composition, mechanical properties, and fabrication:

| Standard Type | Applicable Codes |

|---|---|

| Material Standards | ASTM B168 (plate/sheet), ASTM B906 (strip), EN 1.4529, UNS N08926 |

| Fabrication Certifications | ASME Sec. VIII, VdTÜV (196-400°C) |

| Welding Fillers | ERNiCrMo-3 (Alloy 625), ERNiCrMo-12 |

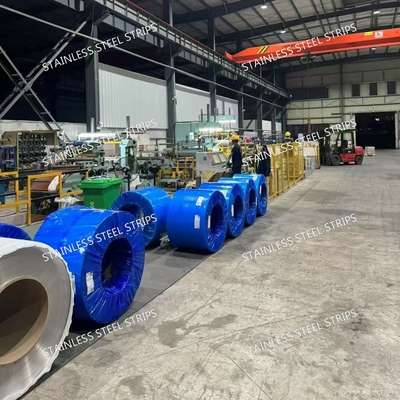

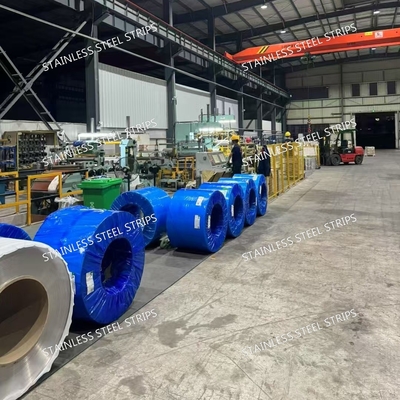

926 stainless steel strip is supplied in cold-rolled, solution-annealed, and descaled conditions. Common dimensions include:

| Parameter | Range |

|---|---|

| Thickness | 0.1-5.0 mm |

| Width | 10-2000 mm |

| Surface Finish | No. 1 (annealed), 2B (smooth), BA (bright annealed) |

Other forms: Sheets, coils, foil (custom widths/lengths available)

- Corrosion Superiority: Outperforms 904L, 316L, and duplex steels in chloride/sulfide media

- Cost Efficiency: Economical alternative to nickel alloys (e.g., Hastelloy) in marine/chemical systems

- Mechanical Robustness: 35% elongation enables deep drawing; high strength allows thinner sections

- Weldability: Maintains corrosion resistance post-welding with proper fillers

Alloy 926 strip is critical in:

| Industry | Specific Use Cases |

|---|---|

| Marine Engineering | Seawater piping, desalination plants (RO membranes), shipboard systems |

| Pollution Control | FGD scrubbers, ducting, chimneys |

| Chemical Processing | Heat exchangers, reactors, acid storage tanks |

| Oil & Gas | Polished rods for corrosive wells, subsea components |

| Energy | Condensers using wastewater cooling |

- Key Suppliers: Shanghai Baoyuan Steel, Shanghai Weili Metal

- Handling Tips:

- Avoid sulfur contamination during heat treatment (max 0.1% in fuel)

- Cold working >15% requires re-solution annealing

For detailed specifications or testing reports, consult manufacturer datasheets or standards (e.g., ASTM B168, EN 1.4529).