-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

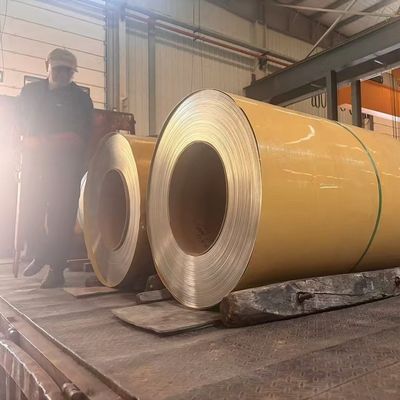

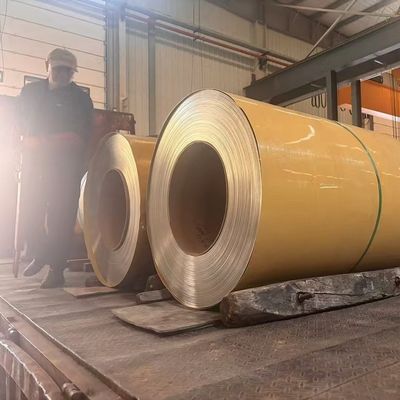

EN 10095 1999 Grade 1.4828 Stainless Steel Sheet 0.5 - 20.0mm Alloy 1.4828 Plate

| Products | Stainless Steel Plate | Grade | 1.4828 |

|---|---|---|---|

| Width | 1500mm 1219mm 1000mm | Surface | NO.1 2B |

| Brand | POSCO TISCO BAOSTEEL | Standard | EN 10095:1999 |

| Loading Port | Shanghai Port | Thickness | 0.4 - 20.0mm |

| Highlight | Alloy 1.4828 Stainless Steel Sheet,1.4828 Stainless Steel Sheet,20.0mm Stainless Steel Sheet |

||

EN 10095:1999 Grade 1.4828 Stainless Steel Sheet 0.5 - 20.0mm Alloy 1.4828 Plate

Products Specification

| Product name | 1.4828 Stainless steel Sheet / plate |

| Standard | EN 10095:1999 |

| Thickness | 0.4 - 20.0mm |

| Width | 1219, 1500mm, or as your requirements |

| Length | 2438, 3000,6000mm, or as your requirements |

| MOQ | 1MT |

| Surface | 2B NO.1 |

| Packing | standard export packing (inside:water proof paper,outside:steel covered with strips and pallets) |

| Similar Grade We Can Supply | 321, 310S |

| Delivery Time | About 5-7 days after receive the deposit. |

Regular Size of 1.4828 Stainless Steel Sheet / Plate in Stock

| 0.4*1219*2438mm | 0.5*1219*2438mm | 0.6*1219*2438mm | 0.8*1219*2438mm |

| 1.0*1219*2438mm | 1.2*1219*2438mm | 1.5*1219*2438mm | 2.0*1219*2438mm |

| 2.5*1219*2438mm | 3.0*1219*2438mm | 4.0*1500*6000mm | 5.0*1500*6000mm |

| 6.0*1500*6000mm | 8.0*1500*6000mm | 10.0*1500*6000mm | 12.0*1500*6000mm |

| 14.0*1500*6000mm | 16.0*1500*6000mm | 20.0*1500*6000mm |

Stainless Steel DIN 1.4828

Stainless Steel DIN 1.4828 stands out as a high-performance alloy, renowned for its exceptional heat and corrosion resistance. Often known as AISI 309 or UNS S30900, this material is highly valued in industries that demand resilience against extreme temperatures and harsh environments. Its balanced chromium and nickel composition, combined with silicon, significantly enhances its resistance to oxidation while allowing it to maintain structural integrity at elevated temperatures. This alloy is ideal for both continuous and intermittent high-temperature applications, offering versatility across a wide range of industrial uses.

Chemical and Physical Properties

Overview of DIN 1.4828 (AISI 309) Stainless Steel Alloy

DIN 1.4828, or AISI 309, is a stainless steel alloy renowned for its remarkable strength and resistance to heat and corrosion. This makes it a preferred choice for various demanding industrial applications.

Chemical Composition

- Chromium (Cr): Present at 19-21%, chromium is key to the alloy’s superb resistance to rust and heat.

- Nickel (Ni): At 11-13%, nickel enhances the alloy’s ability to withstand high temperatures and maintain its structure.

- Carbon (C): Controlled levels between 0.08% and 0.20% help maintain the alloy’s strength at high temperatures.

- Silicon (Si): Ranging from 1-2.5%, silicon improves the alloy’s ability to handle thermal stress.

- Manganese (Mn): At 1.5-2.5%, manganese enhances the alloy’s mechanical properties.

- Phosphorus (P) and Sulfur (S): Both are kept low to maintain toughness and weldability.

- Nitrogen (N): Up to 0.11%, nitrogen boosts strength without sacrificing corrosion resistance.

- Molybdenum (Mo) and Copper (Cu): Each up to 0.75%, they improve corrosion resistance in specific settings.

Physical Properties

- Density: Approximately 7.9 g/cm³, striking a balance between strength and weight.

- Hardness: Levels ensure it can handle high heat without losing machinability.

- Tensile and Yield Strength: With tensile strength up to 750 MPa and yield strength around 205 MPa, this alloy is both strong and flexible.

- Elongation and Formability: Its 30-50% elongation means it’s highly ductile and easy to shape.

- Thermal Properties: Require careful handling during machining and welding.

- Electrical Resistance: Suits applications where conductivity isn’t critical.

Mechanical Properties and Processing Behavior

- Machinability and Weldability: The alloy is easy to machine and weld, with standard techniques ensuring minimal stress.

- Formability and Heat Treatment: It handles cold forming well, and solution annealing restores its properties after working.

Key Properties Supporting Applications

- Scale Resistance: Withstands temperatures up to 1000°C without scaling.

- Mechanical Strength: Maintains high tensile and proof stress even at elevated temperatures.

- Corrosion Resistance: Excels in environments with carburizing and nitrogen-rich gases, especially at lower temperatures.

- Weldability: Offers excellent weldability without the need for preheating or post-weld treatment.

DIN 1.4828’s versatility and resilience make it indispensable for industries requiring materials that endure high temperatures and mechanical stress.

![]()

![]()

![]()

![]()