-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

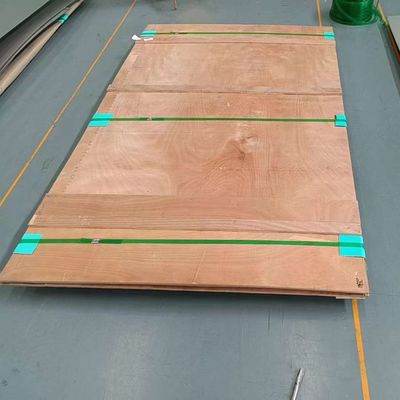

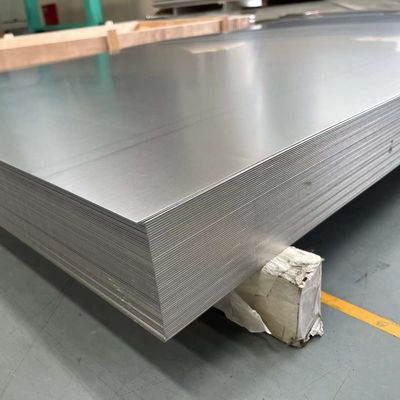

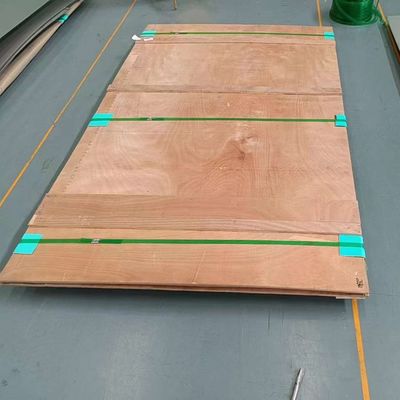

Hot Rolled Stainless Steel Plate 310 / 310S / 310H Heat Resistant Steel Plates Laser Cutting

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | 304 316L 309S 310S 321 347 904L 2205 2507 254SMO |

| Minimum Order Quantity | 400 kgs |

| Price | 2200 -3220 USD/Ton |

| Packaging Details | wooden pallets + waterproof paper |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 10 Ton per week |

| Products | Stainless Steel Plates | Grade | 304 316L 309S 310S 321 347 904L 2205 2507 254SMO |

|---|---|---|---|

| Standard Size | 1000*2000mm 1219*2438mm 1500*6000mm | Thickness | 1.0 - 30.0mm |

| Brand | TISCO BAOSTEEL POSCO LISCO | Loading Port | Shanghai Port |

| MOQ | 200 Kgs | Packing | Wooden Pallets + Waterproof Paper |

| Highlight | Laser Cutting Stainless Steel Plate,310H Stainless Steel Plate,310S Stainless Steel Plate |

||

Hot Rolled Stainless Steel Plate 310 / 310S / 310H Heat Resistant Steel Plates Laser Cutting

|

Material

|

200 300 400 Series stainless steel

|

|

Grade

|

201 202 301 303 304 304L 2205 2507 309 309S 310 310S 314 316L 316Ti 317L 321 2205 2507 409 409l 410 410S 420 420J1 420J2 430 441 444 904L

|

|

Standard

|

AISI ASTM JIS DIN EN BS

|

|

Tech

|

Cold rolled / Hot rolled

|

|

Thickness

|

Hot rolled: 3mm-16mm 16-150mm

Normal: 3.0 4.0 5.0 6.0 8.0 10.0 12.0 14.0 16.0

As per customer's request: 16-150mm Cold rolled: 0.3-6mm

Normal:0.3/0.4/0.5/0.6/0.7/0.8/0.9/1.0/1.2/1.5/2.0/2.5/3.0 As per customer's request: 4.0/5.0/6.0 |

|

Width&Length

|

1000mm-6000mm, or as per customer's request

Hot rolled: 1250*3000mm (4.1*10ft) 1500*3000mm (5*10ft) 1250*6000mm (4.1*19.6ft) 1500*6000mm (5*19.6ft) 1800*6000mm (5.9*19.6ft) 2000*6000mm(6.5*19.6ft) Cold rolled: 1000*2000mm (3.2*6.5ft) 1219*2438mm (4*8ft) 1500*3000mm (5*10ft) 1800 available 2000 available |

|

Place of Origin

|

Jiangsu China

|

|

Processing Service

|

Bending, Welding, Recoiling, Punching, Cutting

|

|

Tolerance

|

±1%

|

|

Surface Treatment

|

N0.1,2B,BA,6K, 8K, 12k, N0.4, HL, Mirrored,checkered etc

|

|

Payment

|

T/T terms, 30% pre-payment, 70% balance see B/L copy LC Western Union Paypal

|

|

Delivery Time

|

5-15 days for ordinary orders (standard orders <=50 ton); specified orders needs final confirmation as per customer's request

|

Grade 310, 310S, 310H

Grade 310 (UNS S31000) and its various subgrades combine excellent high temperature properties with good ductility and weldability.

Grade 310H (UNS S31009) has a carbon content restricted to exclude the lower end of the 310 range, so is the grade of choice for high temperature applications.

Grade 310S (UNS S31008) is used when the application environment involves moist corrodents in a temperature range lower than that which is normally considered "high temperature" service. The lower carbon content of 310S does reduce its high temperature strength compared to 310H.

Grade 310L is a series of proprietary grades, generally with a 0.03% maximum carbon and sometimes used for very specific corrosive environments such as urea production.

Like other austenitic grades the 310 family have excellent toughness, even down to cryogenic temperatures, although other grades are normally used in sub-zero environments.

Corrosion Resistance

The high chromium content - intended to increase high temperature properties – also gives these grades good aqueous corrosion resistance. The PRE is approximately 25, and sea water

resistance about 22°C, similar to that of Grade 316. In high temperature service they exhibit good resistance to oxidising and carburising atmospheres. Resist fuming nitric acid at room temperature and fused nitrates up to 425°C.

The high carbon contents of all except 310L do make these grades susceptible to sensitisation and hence intergranular corrosion after elevated temperature exposure or welding.

310 is subject to stress corrosion cracking but more resistant than Grades 304 or 316.

Heat Resistance

310H has good resistance to oxidation in intermittent service in air at temperatures up to 1040°C and 1150°C in continuous service. Good resistance to thermal fatigue and cyclic heating. Widely used where sulphur dioxide gas is encountered at elevated temperatures. Continuous use in 425- 860°C range not recommended due to carbide precipitation, if subsequent aqueous corrosion

resistance is needed, but it often performs well in temperatures fluctuating above and below this range. Prone to sigma phase embrittlement in the temperature range 650 – 900°C.

Grade 310H is generally used at temperatures starting from about 800 or 900°C - above the temperatures at which 304H and 321 are effective.

Heat Treatment

Solution Treatment (Annealing)

Heat to 1040-1150°C and cool rapidly for maximum corrosion resistance. This treatment

is also recommended to restore ductility after each 1000 hours of service above 650°C, due to long term precipitation of brittle sigma phase.

These grades cannot be hardened by thermal treatment.

Welding

Good characteristics suited to all standard methods. Grade 310S electrodes generally

recommended for fusion welding. AS 1554.6 pre-qualifies welding of 310 with Grade 310 rods or electrodes.

“Dual Certification”

310H and 310S are often produced in "Dual Certified" form – mainly in plate and pipe. These items have chemical and mechanical properties complying with both 310H and 310S specifications.

Product complying with 310 only or dual certified 310 and 310S may have a carbon content below 0.04% which will not be acceptable for some high temperature applications.

Typical Applications

Furnace parts. Oil burner parts. Carburising boxes. Heat Treatment baskets and jigs. Heat exchangers. Welding filler wire and electrodes.

Specified Properties

These properties are specified for flat rolled product (plate, sheet and coil) in ASTM A240/A240M (310S and 310H) and ASTM A167 (310). Similar but not necessarily identical properties are

specified for other products such as pipe and bar in their respective specifications.

Composition Specification (%) (Single values are maxima)

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 310 | min. max. |

- 0.25 |

- 2.00 |

- 1.50 |

- 0.045 |

- 0.030 |

24.0 26.0 | - | 19.0 22.0 | - |

| 310S | min. max. |

- 0.08 |

- 2.00 |

- 1.50 |

- 0.045 |

- 0.030 |

24.0 26.0 | - | 19.0 22.0 | - |

| 310H | min. max. | 0.04 0.10 |

- 2.00 |

- 0.75 |

- 0.045 |

- 0.030 |

24.0 26.0 | - | 19.0 22.0 | - |

Mechanical Property Specification

| Grade |

Tensile Strength (MPa) min. |

Yield Strength 0.2% Proof (MPa) min. |

Elongation (% in 50mm) min. |

Hardness | |

|

Rockwell B (HR B) max. |

Brinell (HB) max. |

||||

| 310 | 515 | 205 | 40 | 95 | 217 |

| 310S | 515 | 205 | 40 | 95 | 217 |

| 310H | 515 | 205 | 40 | 95 | 217 |

Physical Properties (Typical values in the annealed condition)

| Grade | Density (kg/m3) |

Elastic Modules (GPa) |

Mean Coefficient of Thermal Expansion |

Thermal Conductivity |

Specific Heat | Electrical Resistivity | |||

| 0-100°C (µm/m/°C) | 0-315°C (µm/m/°C) | 0-538°C (µm/m/°C) | at 100°C (W/m.K) | at 500°C (W/m.K) | 0-100°C (J/kg.K) | (nΩ.m) | |||

| 310/S/H | 7750 | 200 | 15.9 | 16.2 | 17.0 | 14.2 | 18.7 | 500 | 720 |

Grade Specification Comparison

| Grade | UNS No | Euronorm | Swedish SS | Japanese JIS | |

| No | Name | ||||

| 310S | S31008 | 1.4845 | X8CrNi25-21 | 2361 | SUS 310S |

|

There are no known international specification equivalents to ASTM grades 310, 310H etc. These comparisons are approximate only. The list is intended as a comparison of functionally similar materials not as a schedule of contractual equivalents. If exact equivalents are needed original specifications must be consulted. Heat resistant grades have poor agreement between different specification systems. |

|||||

Possible Alternative Grades

| Grade | Why it might be chosen instead of 310, 310S, 310H |

| 3CR12 | Heat resistance is needed, but only to about 600°C. |

| 304H | Heat resistance is needed, but only to about 800°C. |

| 321 | Heat resistance is needed, but only to about 900°C. Subsequent aqueous corrosion resistance also required. |

|

253MA (UNS S30815) |

A slightly higher temperature resistance is needed than can be provided by 310. Better resistance to reducing sulphide atmosphere needed. Higher immunity from sigma phase embrittlement is required. |

![]()

![]()

![]()

![]()