Todos os Produtos

-

Raian IonescuQualidade material muito boa. nós temos cooperar mais de 10 anos. Trocam tipos dos lotes do material de aço. Toda a qualidade material boa. Eles dever para toda a qualidade material. Nós estamos aplanando para continuar a cooperar no futuro com eles

Raian IonescuQualidade material muito boa. nós temos cooperar mais de 10 anos. Trocam tipos dos lotes do material de aço. Toda a qualidade material boa. Eles dever para toda a qualidade material. Nós estamos aplanando para continuar a cooperar no futuro com eles

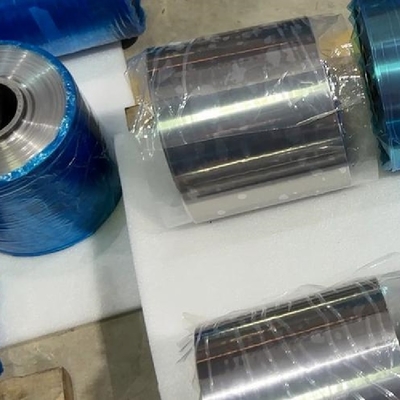

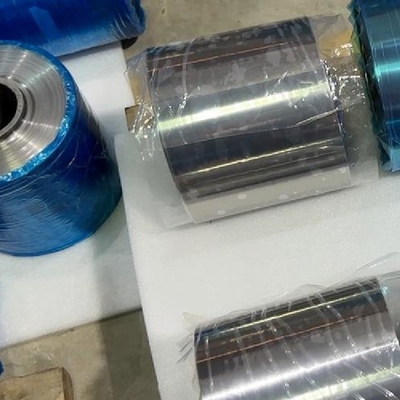

Fita de Precisão de Liga de Níquel C276 | Fita Fina Resistente à Corrosão

| Lugar de origem | China |

|---|---|

| Marca | DELTA |

| Certificação | ISO |

| Número do modelo | UNS N10276 |

| Quantidade de ordem mínima | 500 kgs |

| Preço | 40-45 USD/Kg |

| Detalhes da embalagem | Embalagem padrão para exportação |

| Tempo de entrega | 5 - 12 dias com base na quantidade |

| Termos de pagamento | L/C, T/T, Western Union |

| Habilidade da fonte | 3 toneladas por semana |

Contacte-me para amostras grátis e vales.

whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Se você tem algum interesse, nós fornecemos a ajuda online de 24 horas.

xDetalhes do produto

| Produtos | Tiras Hastelloy C276 | Nota | UNS N10276 |

|---|---|---|---|

| Grossura | 0,1 - 2,5 mm | Largura | 1000 mm 1219 mm 1500 mm |

| Padrão | ASTM EN | SERVIÇO | tiras de corte personalizadas em qualquer largura e espessura |

| Porta de carregamento | Porto de Xangai | Superfície | 2B NÃO.1 |

| Destacar | Banda de precisão de liga de níquel C276,Faixa de liga de níquel resistente à corrosão,Faixa fina de liga C276 |

||

Descrição de produto

Faixa de precisão de liga de níquel C276.

Informações rápidas

| Grau | Hastelloy C276 / 2.4819 | Tipo | Lâmina |

| Espessura | 0.1 - 2,5 mm | Largura | 5 - 1219 mm conforme pedido |

| Superfície | 2B | Diâmetro interno | 508 mm ou conforme pedido |

Mais informações de especificações

| Nome dos produtos | Hastelloy C276 Ligas de liga de níquel |

| Espessura | 0.1 - 2,5 mm |

| Largura | 5 - 1219 mm |

| Superfície | 2B |

| Marca | DELTA |

| Serviço | Processamento de pequenas bobinas |

| MOQ | 2 kg |

| Outros tipos | Barra redonda, folha, chapa, bobina, tubo, etc. |

| Embalagem | Papel impermeável e paletes de madeira, caixa de madeira |

| Porto de carga | Porto de Xangai |

| Prazo do preço | EXW, FOB, CIF, CFR |

| Tempo de entrega | no prazo de 12 dias |

Faixa de precisão de liga de níquel C276.

1Introdução à faixa de precisão de liga de níquel C276

liga de níquel C276 (também conhecida como Hastelloy® C276,uma marca registada da Haynes International) a fita de precisão é um produto de metal fino de alto desempenho concebido para aplicações extremamente resistentes à corrosãoComposto principalmente de níquel (mínimo de 57%), molibdênio (15-17,5%), cromo (14,5-16,5%) e tungstênio (3-4,5%), com vestígios de ferro, cobalto, carbono e silício,Esta liga apresenta uma resistência excepcional a ambientes oxidantes e redutivos, um atributo que a distingue de muitas outras ligas à base de níquel.

A "precisão" no seu nome refere-se às suas tolerâncias de fabrico apertadas: espessura normalmente varia de 0,01 mm a 2,0 mm, largura de 5 mm a 600 mm, e acabamentos de superfície (como 2B, BA,ou polidos) adaptados às necessidades específicas da aplicaçãoO seu diâmetro fino, combinado com uma resistência mecânica superior (mesmo a temperaturas elevadas de até 1093°C/2000°F) e ductilidade,torna-o ideal para componentes que exigem proteção contra corrosão e precisão dimensionalAo contrário das tiras metálicas normais, a tira de precisão C276 é submetida a um rigoroso controlo de qualidade, incluindo testes ultrasónicos, verificação da composição química e validação das propriedades mecânicas,para garantir a consistência em cada lote.

2Parâmetros técnicos essenciais

O desempenho da fita de precisão de liga de níquel C276 é definido pela sua estrita conformidade com os padrões de materiais e dimensões.

| Categoria de parâmetros | Detalhes específicos |

|---|---|

| Composição química | - Níquel (Ni): ≥ 57% - Molibdênio (Mo): 15,0-17,5% - Cromo (Cr): 14,5-16,5% - Tungsténio (W): 3,04,5% - Ferro (Fe): ≤ 5,0% - Cobalto (Co): ≤ 2,5% - Carbono (C): ≤ 0,01% - Silício (Si): ≤ 0,08% - Manganês (Mn): ≤ 1,0% |

| Propriedades mecânicas (condição de aquecimento) | - Resistência à tração: ≥ 690 MPa - Resistência ao rendimento (0,2% de deslocamento): ≥ 275 MPa - alongamento (em 50 mm): ≥ 40% |

| Tolerâncias Dimensionais | - Tolerância de espessura: ±0,001 mm (para tiras de espessura < 0,1 mm); ±2% (para tiras de espessura > 0,1 mm) - Tolerância de largura: ±0,05 mm - Planosidade: ≤ 0,5 mm/m |

| Resistência à corrosão | - Resiste ao ácido sulfúrico (concentração até 90%), ácido clorídrico, ácido fosfórico e água do mar - Nenhuma corrosão por fendas ou fissuras em ambientes ricos em cloretos - Resistência à oxidação até 1093°C (2000°F) |

| Revestimento de superfície | - 2B (matte, laminado a frio): Adequado para utilizações industriais gerais - BA (brilhante, laminado a frio): Ideal para componentes decorativos ou visíveis - Polido (Ra ≤ 0,05 μm): Para aplicações de alta pureza (por exemplo, semicondutores) |

3Normas de conformidade

A fita de precisão de liga de níquel C276 adere aos padrões mundiais da indústria para garantir a interoperabilidade e confiabilidade entre os setores.

-

ASTM Internacional:

- ASTM B575: Especificação padrão para ligas de níquel-cromo-molibdênio-colúbnio (Ni-Cr-Mo-Nb) (UNS N06625) e ligas de níquel-cromo-molibdênio-tungsténio (Ni-Cr-Mo-W) (UNS N06455, UNS N06985,N.o UNS 06986, UNS N06992, UNS N07718) Chapas, folhas e tiras (abrange o C276 como UNS N10276).

- ASTM B906: Especificação padrão para liga de níquel-ferro-cromo-molibdênio-cobre (UNS N08926) e liga de níquel-cromo-molibdênio-tungsténio (UNS N10276) para sensores de pressão.

-

ISO (Organização Internacional de Normalização):

- ISO 6208: Níquel e ligas de níquel ¢ Placas, folhas e tiras (inclui C276 sob a designação NiMo16Cr15W).

-

DIN (Deutsches Institut für Normung):

- DIN EN 10095: Níquel e ligas de níquel ¢ Placas, folhas e tiras (conforme às normas europeias para C276).

-

UNS (Sistema Unificado de Numeração):

- UNS N10276: A designação oficial da liga para o C276 na América do Norte, garantindo a consistência na identificação do material.

4Aplicações típicas

Graças à sua resistência à corrosão, dimensões precisas e estabilidade a altas temperaturas,A fita de precisão C276 é amplamente utilizada em indústrias onde a falha devido à corrosão ou a uma imprecisão dimensional teria graves consequênciasAs principais aplicações incluem:

-

Processamento químico:

- Acoplamentos, diafragmas e revestimentos de parede fina para reatores que tratam de substâncias químicas agressivas (por exemplo, ácido sulfúrico, ácido clorídrico).

- Casos de sensores e medidores de caudal que exijam resistência à degradação química.

-

Petróleo e Gás:

- Componentes de ferramentas de perfuração (por exemplo, mangas de parede fina) para perfuração offshore, onde a exposição a água salgada e hidrocarbonetos de alta pressão exige uma resistência extrema à corrosão.

- Assentos e vedações de válvulas em tubulações submarinas.

-

Produção farmacêutica e de alimentos:

- Fitas finas para equipamentos estéreis (por exemplo, revestimentos de misturadores, carcaças de filtros) devido às suas propriedades não reativas e capacidade de suportar desinfecção frequente (por vapor ou produtos químicos).

-

Aeronáutica e Defesa:

- Escudos térmicos e revestimentos de câmara de combustão para motores a jato, pois mantém a resistência a altas temperaturas (até 1093 °C).

- Componentes para sistemas de orientação de mísseis, onde a precisão e a resistência a ambientes adversos são críticos.

-

Fabricação de semicondutores:

- Equipamento de manuseio de wafers (por exemplo, garras finas, barras eletrostáticas) que exige superfícies ultralimpas e resistência a ésteres corrosivos (por exemplo, ácido fluorídrico).

-

Engenharia Ambiental:

- Suportes de membrana para instalações de tratamento de água (por exemplo, sistemas de osmose reversa) e depuradores de gases de escape, onde a exposição a cloretos e soluções ácidas é comum.

5Outros produtos de liga de níquel C276

Além da fita de precisão, a liga de níquel C276 é fabricada em várias formas para atender a diversos requisitos de aplicação.Estes produtos aproveitam as mesmas propriedades resistentes à corrosão do núcleo, mas são otimizados para formas e casos de uso específicos:

- C276 Placa e folha: Mais espessa que a fita (normalmente de 2 mm a 100 mm), utilizada para recipientes sob pressão, revestimentos de tanques e componentes estruturais em instalações químicas.

- C276 Tubos e tubos: sem costura ou soldados, utilizados em tubulações para fluidos corrosivos (por exemplo, linhas de transferência de ácidos) e trocadores de calor.

- C276 Fios e folhas: Folhas (mais finas que 0,01 mm) para juntas flexíveis e componentes de baterias; fios para termopares e conectores elétricos em ambientes de alta temperatura.

- C276 Forja e fundição: peças forjadas (por exemplo, corpos de válvulas, rotores de bomba) para equipamentos industriais pesados; fundições para formas complexas que exijam resistência à corrosão uniforme.

- Ferramentas de fixação C276: parafusos, porcas e rolhas utilizados para montar componentes sensíveis à corrosão, garantindo a compatibilidade com os materiais de base C276.

![]()

![]()

![]()

![]()

Produtos recomendados