모든 제품

-

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

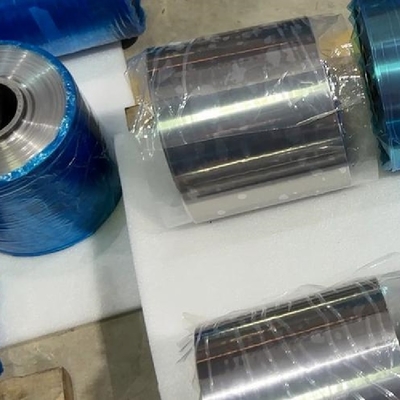

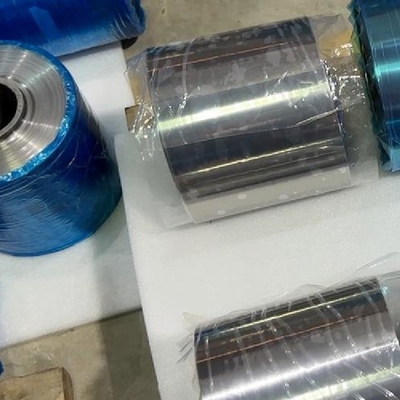

니켈 합금 C276 정밀 스트립

무료샘플과 쿠폰을 위해 나와 연락하세요.

왓츠앱:0086 18588475571

위챗: 0086 18588475571

스카이프: sales10@aixton.com

만약 당신이 어떠한 관심도 가지면, 우리가 24 시간 온라인 도움말을 제공합니다.

x제품 상세 정보

| 제품 | Hastelloy C276 스트립 | 등급 | UNS N10276 |

|---|---|---|---|

| 두께 | 0.1-2.5mm | 너비 | 1000 밀리미터 1219 밀리미터 1500 밀리미터 |

| 표준 | astm en | 서비스 | 모든 너비와 두께의 맞춤형 절단 스트립 |

| 로딩 포트 | 상하이 항구 | 표면 | 2B NO.1 |

| 강조하다 | 니켈 합금 C276 정밀 스트립,내식성 니켈 합금 스트립,얇은 C276 합금 스트립 |

||

제품 설명

니켈 합금 C276 정밀 스트립 | 부식 방지 얇은 스트립

빠른 정보

| 등급 | Hastelloy C276 / 2.4819 | 유형 | 스트립 |

| 두께 | 0.1-2.5mm | 너비 | 요청대로 5-1219mm |

| 표면 | 2B | 인더 직경 | 508mm 또는 요청으로 |

더 많은 사양 정보

| 제품 이름 | Hastelloy C276 니켈 합금 스트립 |

| 두께 | 0.1-2.5mm |

| 너비 | 5-1219mm |

| 표면 | 2B |

| 상표 | 델타 |

| 서비스 | 작은 코일 가공 |

| 모크 | 2kg |

| 다른 유형 | 둥근 막대, 시트, 플레이트, 코일, 파이프 .ETC |

| 포장 | 방수 종이와 나무 팔레트, 나무 상자 |

| 로딩 포트 | 상하이 항구 |

| 가격 기간 | exw, fob, cif, cfr |

| 시간을 전달하십시오 | 12 일 이내에 |

니켈 합금 C276 정밀 스트립 | 부식 방지 얇은 스트립

1. 니켈 합금 C276 정밀 스트립 소개

니켈 합금 C276 (Haynes International의 등록 상표 인 Hastelloy® C276이라고도 함) Precision Strip은 극도의 부식 방지 응용 프로그램을 위해 고성능 얇은 금속 제품입니다. 주로 니켈 (57%최소), 몰리브덴 (15-17.5%), 크롬 (14.5-16.5%) 및 텅스텐 (3-4.5%)으로 구성되어 철, 코발트, 탄소 및 실리콘의 트레이스 양이 산화 환경과 감소하는 것으로 예외적 인 저항성을 나타냅니다.

이름의 "정밀도"는 단단한 제조 공차를 나타냅니다. 두께는 일반적으로 0.01mm ~ 2.0mm, 폭은 5mm ~ 600mm, 특정 응용 분야 요구에 맞게 조정 된 표면 마감재 (예 : 2B, BA 또는 연마)입니다. 얇은 게이지는 우수한 기계적 강도 (최대 1093 ° C/2000 ° F의 높은 온도에서도)와 연성과 결합하여 부식 방지 및 치수 정확도를 모두 필요한 구성 요소에 이상적으로 만듭니다. 표준 금속 스트립과 달리 C276 정밀 스트립은 모든 배치의 일관성을 보장하기 위해 초음파 테스트, 화학 조성 검증 및 기계적 특성 검증을 포함한 엄격한 품질 관리를 겪습니다.

2. 주요 기술 매개 변수

니켈 합금 C276 정밀 스트립의 성능은 재료 및 치수 표준에 대한 엄격한 준수에 의해 정의됩니다. 다음은 핵심 기술 매개 변수입니다.

| 매개 변수 범주 | 구체적인 세부 사항 |

|---|---|

| 화학 성분 | - 니켈 (NI) : ≥57% - Molybdenum (MO) : 15.0-17.5% - 크롬 (CR) : 14.5-16.5% - 텅스텐 (W) : 3.0-4.5% - 철 (FE) : ≤5.0% - 코발트 (CO) : ≤2.5% - 탄소 (C) : ≤0.01% - 실리콘 (SI) : ≤0.08% - 망간 (MN) : ≤1.0% |

| 기계적 특성 (어닐링 된 상태) | - 인장 강도 : ≥690 MPa - 항복 강도 (0.2% 오프셋) : ≥275 MPa - 신장 (50mm) : ≥40% |

| 치수 공차 | - 두께 내성 : ± 0.001 mm (스트립 <0.1 mm 두께); ± 2% (스트립> 0.1 mm 두께) - 폭 내성 : ± 0.05 mm - 평탄도 : ≤0.5 mm/m |

| 부식 저항 | - 황산 (최대 90% 농도), 염산, 인산 및 해수에 저항 - 염화물이 풍부한 환경에서는 구덩이 또는 틈새 부식이 없습니다 - 최대 1093 ° C (2000 ° F)의 산화 저항 |

| 표면 마감 | -2B (매트, 콜드 롤링) : 일반적인 산업용 사용에 적합합니다 -BA (밝고 냉간 롤링) : 장식 또는 가시 구성 요소에 이상적입니다. - 연마 (RA ≤0.05 μm) : 고급 응용 분야 (예 : 반도체) |

3. 준수 표준

니켈 합금 C276 정밀 스트립은 글로벌 산업 표준을 준수하여 부문 간의 상호 운용성 및 신뢰성을 보장합니다. 주요 표준은 다음과 같습니다.

-

ASTM International :

- ASTM B575 : Nickel-Chromium-Molybdenum-Columbium (NI-CR-MO-NB) 합금 (UNS N06625) 및 니켈-크롬-몰리브덴-텅스텐 (NI-CR-MO-W) 합금 (UNS N06455, UNS N06985, UNS N06986, N0692, UNS N0691)에 대한 표준 사양. 시트 및 스트립 (C276을 UN110276으로 덮음).

- ASTM B906 : 압력 센서에 대한 니켈-아이언-크로미늄-몰리 늄-코퍼 합금 (UNS N08926) 및 니켈-크롬-몰리브덴-텅스텐 합금 (UNS N10276) 스트립에 대한 표준 사양.

-

ISO (국제 표준화기구) :

- ISO 6208 : 니켈 및 니켈 합금 - 플레이트, 시트 및 스트립 (명칭 NIMO16CR15W에 따라 C276 포함).

-

DIN (Deutsches Institut für Normung) :

- DIN EN 10095 : 니켈 및 니켈 합금 - 플레이트, 시트 및 스트립 (C276의 유럽 표준을 준수).

-

UN (Unified Numbering System) :

- UNS N10276 : 북미 지역의 C276에 대한 공식 합금 지정으로 재료 식별의 일관성을 보장합니다.

4. 일반적인 응용 프로그램

부식성, 정밀 치수 및 고온 안정성 덕분에 C276 정밀 스트립은 부식 또는 차원 부정확성으로 인한 고장이 심각한 결과를 초래하는 산업에서 널리 사용됩니다. 주요 응용 프로그램에는 다음이 포함됩니다.

-

화학적 처리 :

- 공격적인 화학 물질 (예 : 황산, 염산)을 처리하는 반응기를위한 개스킷, 다이어프램 및 얇은 벽 라이너.

- 화학 분해에 대한 저항이 필요한 센서 하우징 및 유량계.

-

석유 및 가스 :

- 바닷물 및 고압 탄화수소에 노출되면 해양 시추를위한 다운 홀 도구 구성 요소 (예 : 얇은 벽 소매)는 극도의 부식 저항이 필요합니다.

- 해저 파이프 라인의 밸브 시트 및 씰.

-

제약 및 식품 가공 :

- 비 반응성 특성과 빈번한 소독을 견딜 수있는 능력으로 인해 멸균 장비 (예 : 블렌더 라이너, 필터 하우징)를위한 얇은 스트립 (증기 또는 화학 물질을 통해).

-

항공 우주 및 방어 :

- 제트 엔진 용 열 방패 및 연소 챔버 라이너는 고온 (최대 1093 ° C)에서 강도를 유지하므로 제트 엔진 용.

- 가혹한 환경에 대한 정밀도와 저항이 중요한 미사일 안내 시스템의 구성 요소.

-

반도체 제조 :

- 웨이퍼 취급 장비 (예 : 얇은 발톱, 정전기 척)는 초고속 표면과 부식성 에테치에 대한 저항 (예 : Hydrofluoric Acid)이 필요합니다.

-

환경 공학 :

- 막은 수처리 식물 (예 : 역삼 투스 시스템) 및 배기 가스 세정기를지지하며, 클로라이드 및 산성 용액에 대한 노출이 일반적입니다.

5. 기타 니켈 합금 C276 제품

정밀 스트립 이외에도 니켈 합금 C276은 다양한 응용 프로그램 요구 사항을 충족하기 위해 다양한 형태로 제조됩니다. 이 제품들은 동일한 코어 부식 내성 특성을 활용하지만 특정 모양 및 사용 사례에 최적화됩니다.

- C276 플레이트 및 시트 : 압력 용기, 탱크 라이너 및 화학 식물의 구조 성분에 사용되는 스트립보다 두껍고 (일반적으로 2mm ~ 100mm).

- C276 파이프 및 튜브 : 원활하거나 용접, 부식성 유체 (예 : 산성 전이선) 및 열교환기를 위해 파이프 라인에 사용됩니다.

- C276 와이어 및 포일 : 유연한 개스킷 및 배터리 구성 요소의 호일 (0.01mm보다 얇음); 고온 환경에서 열전대 및 전기 커넥터 용 와이어.

- C276 Forting & Castings : 중장비 산업 장비를위한 단조 부품 (예 : 밸브 바디, 펌프 임펠러); 균일 한 부식 저항이 필요한 복잡한 모양을위한 주물.

- C276 패스너 : 부식에 민감한 구성 요소를 조립하는 데 사용되는 볼트, 너트 및 와셔.

![]()

![]()

![]()

![]()

추천된 제품