Όλα τα Προϊόντα

-

Raian IonescuΥλική ποιότητα πολύ υψηλή. πρέπει να συνεργαστούμε περισσότερο από 10 έτη. Ανταλλάσσουν τα είδη μερών υλικού χάλυβα. Όλο το υλικό ποιοτικό αγαθό. Αυτοί δασμός για όλη την υλική ποιότητα. Πλανίζουμε συνεχιζόμαστε συνεργαζόμαστε με τους στο μέλλον

Raian IonescuΥλική ποιότητα πολύ υψηλή. πρέπει να συνεργαστούμε περισσότερο από 10 έτη. Ανταλλάσσουν τα είδη μερών υλικού χάλυβα. Όλο το υλικό ποιοτικό αγαθό. Αυτοί δασμός για όλη την υλική ποιότητα. Πλανίζουμε συνεχιζόμαστε συνεργαζόμαστε με τους στο μέλλον

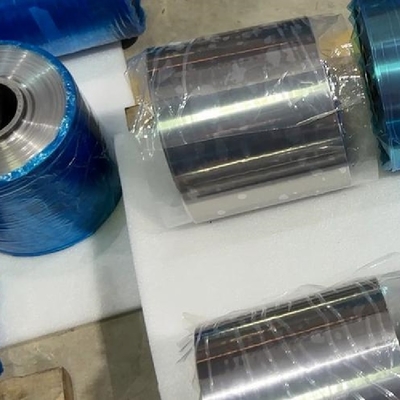

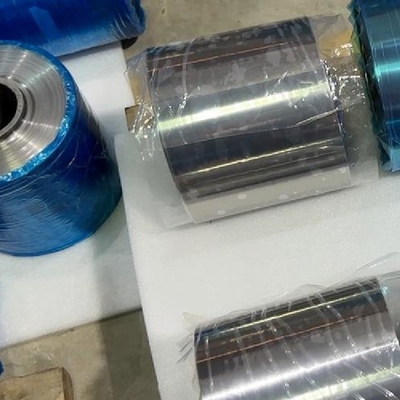

Νικέλιο κράμα C276 ταινία ακρίβειας

| Τόπος καταγωγής | Κίνα |

|---|---|

| Μάρκα | DELTA |

| Πιστοποίηση | ISO |

| Αριθμό μοντέλου | Uns n10276 |

| Ποσότητα παραγγελίας min | 500 κιλά |

| Τιμή | 40-45 USD/Kg |

| Συσκευασία λεπτομέρειες | τυπική συσκευασία για εξαγωγή |

| Χρόνος παράδοσης | 5 - 12 ημέρες με βάση την ποσότητα |

| Όροι πληρωμής | L/C, T/T, Western Union |

| Δυνατότητα προσφοράς | 3 τόνοι την εβδομάδα |

Με ελάτε σε επαφή με δωρεάν δείγματα και δελτία.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Εάν έχετε οποιαδήποτε ανησυχία, παρέχουμε τη 24ωρη σε απευθείας σύνδεση βοήθεια.

xΛεπτομέρειες

| Προϊόντα | Hastelloy C276 λωρίδες | Βαθμός | Uns n10276 |

|---|---|---|---|

| Πάχος | 0,1 - 2,5 χιλιοστά | Πλάτος | 1000 mm 1219 mm 1500 mm |

| Στάνταρ | Astm en | ΥΠΗΡΕΣΙΑ | προσαρμοσμένες λωρίδες κοπής σε οποιοδήποτε πλάτος και πάχος |

| Θύρα φόρτωσης | Λιμάνι της Σαγκάης | Επιφάνεια | 2Β Όχι.1 |

| Επισημαίνω | Καλώδιο C276 από κράμα νικελίου,Τρίχωμα από στερεό νικέλιο ανθεκτικό στη διάβρωση,λεπτή ταινία από κράμα C276 |

||

Περιγραφή προϊόντων

Νικέλιο κράμα C276 ταινία ακρίβειας

Γρήγορες πληροφορίες

| Αξία | Χάστελλοι C276 / 2.4819 | Τύπος | ράβδοι |

| Δάχος | 0.1 - 2,5 mm | Διάμετρο | 5 - 1219 mm κατά αίτηση |

| Επιφάνεια | 2Β | Εσωτερική διάμετρος | 508mm ή κατόπιν αιτήματος |

Περισσότερες πληροφορίες προδιαγραφών

| Ονομασία των προϊόντων | Τρίχες από κράμα νικελίου Hastelloy C276 |

| Δάχος | 0.1 - 2,5 mm |

| Διάμετρο | 5 - 1219 mm |

| Επιφάνεια | 2Β |

| Ετικέτα | ΔΕΛΤΑ |

| Υπηρεσία | Επεξεργασία μικρών κυλίνδρων |

| Τροποποιημένο | 2 κιλά |

| Άλλος τύπος | στρογγυλή ράβδο, φύλλο, πλάκα, σπείρα, σωλήνα κλπ. |

| Συσκευή | υδατοασφαλές χαρτί και ξύλινες παλέτες, ξύλινο κουτί |

| Λιμένας φόρτωσης | Λιμάνι της Σαγκάης |

| Όρος τιμής | Επικαιροποιημένα προϊόντα |

| Χρόνος παράδοσης | εντός 12 ημερών |

Νικέλιο κράμα C276 ταινία ακρίβειας

1. Εισαγωγή στο νικελικό κράμα C276

Νικελικό κράμα C276 (γνωστό επίσης ως Hastelloy® C276,ένα καταχωρισμένο εμπορικό σήμα της Haynes International) η ταινία ακριβείας είναι ένα λεπτό μεταλλικό προϊόν υψηλών επιδόσεων που έχει σχεδιαστεί για εφαρμογές εξαιρετικής αντοχής στη διάβρωσηΑποτελείται κυρίως από νικέλιο (57% τουλάχιστον), μολυβδένιο (15-17.5%), χρώμιο (14.5-16.5%) και βολφράμιο (3-4.5%), με ίχνη σιδήρου, κοβάλτου, άνθρακα και πυριτίου,Αυτό το κράμα παρουσιάζει εξαιρετική αντοχή τόσο σε περιβάλλοντα οξείδωσης όσο και σε περιβάλλοντα μείωσης, ένα χαρακτηριστικό που το διακρίνει από πολλά άλλα κράματα με βάση το νικέλιο..

Η "ακριβότητα" στο όνομά του αναφέρεται στις αυστηρές ανοχές κατασκευής: το πάχος κυμαίνεται συνήθως από 0,01 mm έως 2,0 mm, το πλάτος από 5 mm έως 600 mm και τα επιφανειακά φινίρισμα (όπως 2B, BA,ή γυαλισμένα) προσαρμοσμένα στις ειδικές ανάγκες εφαρμογήςΗ λεπτή του διάμετρος, σε συνδυασμό με την ανώτερη μηχανική αντοχή (ακόμη και σε υψηλές θερμοκρασίες έως 1093°C/2000°F) και την ευελιξία,το καθιστά ιδανικό για στοιχεία που απαιτούν τόσο προστασία από τη διάβρωση όσο και ακρίβεια διαστάσεωνΣε αντίθεση με τις τυπικές μεταλλικές ταινίες, η ταινία ακριβείας C276 υποβάλλεται σε αυστηρό έλεγχο ποιότητας, συμπεριλαμβανομένων των υπερήχων δοκιμών, της επαλήθευσης της χημικής σύνθεσης και της επικύρωσης των μηχανικών ιδιοτήτων,για να εξασφαλίζεται η συνέπεια σε κάθε παρτίδα.

2Βασικές τεχνικές παραμέτρους

Οι επιδόσεις της ταινίας ακριβείας C276 από κράμα νικελίου καθορίζονται από την αυστηρή συμμόρφωσή της με τα πρότυπα υλικών και διαστάσεων.

| Κατηγορία παραμέτρου | Ειδικές λεπτομέρειες |

|---|---|

| Χημική σύνθεση | - Νικέλιο (Ni): ≥ 57% - Μολυβδένιο (Mo): 15,0-17,5% - Χρώμιο (Cr): 14,5-16,5% - Βόλφραμ (W): 3,0-4,5% - Σίδηρος (Fe): ≤ 5,0% - Κοβάλτιο (Co): ≤ 2,5% - Άνθρακας (C): ≤ 0,01% - Σίλην (Si): ≤ 0,08% - Μαγγάνιο (Mn): ≤ 1,0% |

| Μηχανικές ιδιότητες (καύση) | - Δυνατότητα τέντωσης: ≥ 690 MPa - Δυνατότητα απόδοσης (0,2% Offset): ≥275 MPa - Επιμήκυνση (σε 50 mm): ≥ 40% |

| Ανεκτικότητα διαστάσεων | - Δυνατότητα ανοχής πάχους: ±0,001 mm (για ταινίες < 0,1 mm) ±2% (για ταινίες > 0,1 mm) - Ανοχή πλάτους: ±0,05 mm - επίπεδα: ≤ 0,5 mm/m |

| Αντίσταση στη διάβρωση | - Αντιστέκεται στο θειικό οξύ (έως 90% συγκέντρωση), στο υδροχλωρικό οξύ, στο φωσφορικό οξύ και στο θαλάσσιο νερό - Απαγορεύεται η διάβρωση σε ορυχεία ή σχισμές σε περιβάλλοντα πλούσια σε χλωρίδια - Αντίσταση στην οξείδωση έως 1093°C (2000°F) |

| Τελεία επιφάνειας | - 2Β (ματ, έλασης κρύου): Κατάλληλο για γενικές βιομηχανικές χρήσεις - BA (φωτεινά, ψυχρά κυλούμενα): Ιδανικό για διακοσμητικά ή ορατά στοιχεία - Λάμψη (Ra ≤ 0,05 μm): Για εφαρμογές υψηλής καθαρότητας (π.χ. ημιαγωγούς) |

3. Πρότυπα συμμόρφωσης

Η ταινία ακριβείας Nickel Alloy C276 συμμορφώνεται με τα παγκόσμια βιομηχανικά πρότυπα για τη διασφάλιση της διαλειτουργικότητας και της αξιοπιστίας σε όλους τους τομείς.

-

Διεθνής ASTM:

- ASTM B575: Τυποποιημένη προδιαγραφή για κράματα νικελίου-χρωμίου-μολυβδενίου-κολμβίου (Ni-Cr-Mo-Nb) (UNS N06625) και κράματα νικελίου-χρωμίου-μολυβδενίου-τουγκστίνου (Ni-Cr-Mo-W) (UNS N06455, UNS N06985,Αριθμός UNS N06986, UNS N06992, UNS N07718) Πλάκα, φύλλα και ταινίες (καλύπτει το C276 ως UNS N10276).

- Η ASTM B906: Τυποποιημένη προδιαγραφή για κράμα νικελίου-σιδήρου-χρωμίου-μολυβδενίου- χαλκού (UNS N08926) και κράμα νικελίου-χρωμίου-μολυβδενίου-τουγκστάνου (UNS N10276) για ανιχνευτές πίεσης.

-

ISO (Διεθνής Οργάνωση Τυποποίησης):

- ISO 6208: Νικέλιο και κράματα νικελίου ∆ πλάκες, φύλλα και ταινίες (περιλαμβάνει το C276 με την ονομασία NiMo16Cr15W).

-

DIN (Γερμανικό Ινστιτούτο Τυποποίησης):

- DIN EN 10095: Νικέλιο και κράματα νικελίου ∙ Πλάκες, φύλλα και ταινίες (συμμορφούμενες με τα ευρωπαϊκά πρότυπα για το C276).

-

ΕΝΣ (Ενοποιημένο Σύστημα Αριθμολόγησης):

- UNS N10276: Η επίσημη ονομασία κράματος για το C276 στη Βόρεια Αμερική, εξασφαλίζοντας τη συνέπεια στην ταυτοποίηση του υλικού.

4Τυπικές εφαρμογές

Χάρη στην αντοχή της στη διάβρωση, τις ακριβείς διαστάσεις και τη σταθερότητα σε υψηλές θερμοκρασίες,Η ταινία ακρίβειας C276 χρησιμοποιείται ευρέως σε βιομηχανίες όπου η βλάβη λόγω διάβρωσης ή ανακριβείας των διαστάσεων θα είχε σοβαρές συνέπειεςΟι βασικές εφαρμογές περιλαμβάνουν:

-

Χημική μεταποίηση:

- Συμπληρώματα, διαφράγματα και στρώσεις λεπτών τοιχωμάτων για αντιδραστήρες που χειρίζονται επιθετικές χημικές ουσίες (π.χ. θειικό οξύ, υδροχλωρικό οξύ).

- Οικισμοί αισθητήρων και μετρητές ροής που απαιτούν αντοχή σε χημική αποδόμηση.

-

Πετρέλαιο & Αέριο:

- Συσκευάσματα εργαλείων με χαμηλό τρύπο (π.χ. λεπτές τοιχοειδείς μανίκες) για γεωτρήσεις υπεράκτιων περιοχών, όπου η έκθεση σε αλμυρό νερό και υδρογονάνθρακες υψηλής πίεσης απαιτεί εξαιρετική αντοχή στη διάβρωση.

- Κεφάλαια βαλβίδων και σφραγίδες σε υποθαλάσσιους αγωγούς.

-

Φαρμακευτική και Τροφίμων:

- Πενιχρές λωρίδες για αποστειρωμένο εξοπλισμό (π.χ. στρώσεις μπλέντερ, περιβλήματα φίλτρων) λόγω των μη αντιδραστικών ιδιοτήτων τους και της ικανότητάς τους να αντέχουν σε συχνές απολυμαντικές επεξεργασίες (μέσω ατμού ή χημικών ουσιών).

-

Αεροδιαστημική και Άμυνα:

- Θερμικές ασπίδες και στρώσεις θαλάμου καύσης για κινητήρες αεριωθούμενων, καθώς διατηρεί αντοχή σε υψηλές θερμοκρασίες (έως 1093 °C).

- Συστατικά για συστήματα καθοδήγησης πυραύλων, όπου η ακρίβεια και η αντοχή σε σκληρά περιβάλλοντα είναι κρίσιμες.

-

Κατασκευή ημιαγωγών:

- Εξοπλισμός χειρισμού πλακιδίων (π.χ. λεπτά νύχια, ηλεκτροστατικά τσιμπήματα) που απαιτεί εξαιρετικά καθαρές επιφάνειες και αντοχή σε διαβρωτικά ετρωτικά (π.χ. υδροφθορικό οξύ).

-

Μηχανική Περιβάλλοντος:

- Υποστηρίγματα μεμβράνης για εγκαταστάσεις επεξεργασίας νερού (π.χ. συστήματα αντίστροφης όσμωσης) και καθαριστικά καυσαερίων, όπου η έκθεση σε χλωρίδια και όξινα διαλύματα είναι συχνή.

5Άλλα προϊόντα από κράμα νικελίου C276

Πέρα από την ταινία ακριβείας, το κράμα νικελίου C276 κατασκευάζεται σε διάφορες μορφές για να ανταποκρίνεται σε διαφορετικές απαιτήσεις εφαρμογής.Τα προϊόντα αυτά αξιοποιούν τις ίδιες ιδιότητες αντιδράσεως στη διάβρωση, αλλά είναι βελτιστοποιημένα για συγκεκριμένα σχήματα και περιπτώσεις χρήσης.:

- C276 Πλάκα και φύλλο: Πιο παχύ από ταινία (συνήθως 2 mm έως 100 mm), χρησιμοποιείται για δοχεία υπό πίεση, επενδύσεις δεξαμενών και δομικά στοιχεία σε χημικές εγκαταστάσεις.

- C276 Σωλήνες και σωλήνες: Χωρίς συγκόλληση ή συγκόλληση, χρησιμοποιούνται σε αγωγούς για διαβρωτικά υγρά (π.χ. γραμμές μεταφοράς οξέων) και ανταλλακτές θερμότητας.

- C276 Σύρμα και φύλλο: Φόλιο (δυνατότερο από 0,01 mm) για ευέλικτες συμπλέκτες και εξαρτήματα μπαταριών· σύρμα για θερμοσύντομα και ηλεκτρικούς συνδέσμους σε περιβάλλοντα υψηλής θερμοκρασίας.

- C276 Σφυρηλατήσεις και χύτευση: Σφυρηλατημένα μέρη (π.χ. σωλήνες βαλβίδων, τροχούς αντλίας) για βαρέα βιομηχανικά εξοπλισμούς· χύτευση για σύνθετα σχήματα που απαιτούν ομοιόμορφη αντοχή στη διάβρωση.

- C276 Σύνδεσμοι: Στροφές, νάτσες και πλέγματα που χρησιμοποιούνται για την συναρμολόγηση συστατικών ευαίσθητων στη διάβρωση, εξασφαλίζοντας τη συμβατότητα με τα βασικά υλικά C276.

![]()

![]()

![]()

![]()

Συνιστώμενα προϊόντα