-

Striscia di acciaio inossidabile

-

Strato di acciaio inossidabile

-

Piatto di acciaio inossidabile

-

tubo di acciaio inossidabile

-

Acciaio inossidabile Antivari

-

Bobina d'acciaio galvanizzata

-

Piatto d'acciaio

-

tondino d'acciaio

-

lega di nichel

-

Tubo d'acciaio senza cuciture

-

Fascio di acciaio inossidabile

-

Strato del piatto di rame

-

Tondino di rame

-

Raian IonescuQualità materiale molto buona. abbiamo cooperare più di 10 anni. Vendono i generi dei lotti di materiale d'acciaio. Tutta la qualità materiale buona. Essi dovere per tutta la qualità materiale. Stiamo spianando per continuare a cooperare in futuro con loro

Raian IonescuQualità materiale molto buona. abbiamo cooperare più di 10 anni. Vendono i generi dei lotti di materiale d'acciaio. Tutta la qualità materiale buona. Essi dovere per tutta la qualità materiale. Stiamo spianando per continuare a cooperare in futuro con loro

Grado 439 Spessore della lamiera in acciaio inossidabile da 0,8 a 10,0 mm per i sistemi di scarico automobilistici

| Luogo di origine | Cina |

|---|---|

| Marca | TISCO |

| Certificazione | ISO |

| Numero di modello | 439 |

| Quantità di ordine minimo | 500 kg |

| Prezzo | 1.5 - 2USD/Kg |

| Imballaggi particolari | imballaggio standard per l'esportazione |

| Tempi di consegna | 5 - 12 giorni in base alla quantità |

| Termini di pagamento | L/C, T/T, Western Union |

| Capacità di alimentazione | 20ton a settimana |

| prodotti | Lamiera di acciaio inossidabile | Grado | 439 |

|---|---|---|---|

| Spessore | 0,5 - 10,0 | Tecnologia | Arrotolato a freddo |

| Larghezza | 1219mm | Superficie | 2B 2D N.1 |

| Standard | BACCANO DELL'EN DI ASTM GB JIS | MOQ | 1 tonnellata |

| Evidenziare | Fogli di acciaio inossidabile di grado 439,lamiere di acciaio inossidabile per scarico automobilistico,0.8-10.0 mm lamiera di acciaio inossidabile |

||

Grado 439 Spessore della lamiera in acciaio inossidabile da 0,8 a 10,0 mm per i sistemi di scarico automobilistici

Specificativi delle lamiere in acciaio inossidabile

| Nome | 439 Placca di acciaio inossidabile |

| Il nostro grado |

Serie 200: 201 202 Serie 300: 301 304, 304L, 304H, 309S, 310S,314,316L,316Ti,316H,316LN,317L,321,329,347 Serie 400: 409L410,410S,415,416,420,430,431436 litre.439,441,443,444,445,446 Super acciaio inossidabile: 904L,926254SMO, 654SMO, 15-5PH, 17-4PH, 17-7PH, ecc. Lega di nichel: C276, C22, G35, Lega X, Monel 400, K500, Inconel 600,601,617,625,718Incoloy 800,800H,800HT,825. ecc |

| Tecnica | Rotolato a caldo, laminato a freddo, forgiato |

| Norme | JIS, AISI, ASTM, DIN, TUV, BV, SUS, ecc. |

| Spessore | 0.1 ¢ 80,0 mm |

| Intervallo larghezza | 10 mm 2000 mm |

| Distanze | Personalizzato |

| Finisci. | 2B, 2D, NO.1- No, BA.4, 8k, spazzolato, capelli, rivestimento PVD, sabbiato |

| Servizio | Taglio laser, piegatura |

| Campione | Disponibile |

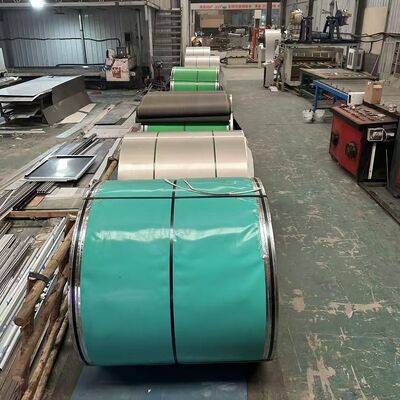

Visualizzazione del prodotto

Perché scegliere il grado 439 per gli scarichi automobilistici?

- Esposizione continua ad alte temperature (fino a 800°C / 1472°F)

- Condensazione di condensati acidi (ad esempio acidi solforico e nitrico)

- Fatica termica da ripetuti cicli di riscaldamento/raffreddamento

- Sale stradale e inquinanti ambientali

- Stabilizzazione con Titanio (Ti): previene la sensibilizzazione durante la saldatura e l'esposizione ad alte temperature mediante il legame del carbonio e dell'azoto, riducendo al minimo la precipitazione di carburo di cromo.

- Basso contenuto di carbonio e azoto: migliora la saldabilità e la resistenza alla corrosione intergranulare.

- Contenuto di cromo del 1719%: fornisce una robusta formazione di strato di ossido passivo per la protezione dalla corrosione.

- Struttura ferritica: offre una buona conduttività termica e una minore espansione termica rispetto ai gradi austenitici (ad esempio, 304), riducendo la distorsione.

Specificità principali

| Immobili | Valore / Intervallo |

|---|---|

| Grado | UNS S43035 / ASTM 439 / EN 1.4510 |

| Spessore | 00,8 mm 10,0 mm |

| Larghezza | 600 mm ️ 2000 mm (personalizzabile) |

| Distanze | Conformemente alle esigenze del cliente (coil o fogli tagliati in lunghezza) |

| Finitura superficiale | 2B, BA (Bright Annealed), n.1, Linea dei capelli, o Custom |

| Norme | ASTM A240, EN 10088-2, JIS G4305, GB/T 4237 |

| Condizione di consegna | Rilasciati e sottaceti, laminati a freddo |

| Certificazioni | ISO 9001, IATF 16949 (gestione della qualità automobilistica), RoHS, rapporti di prova dei materiali (MTR) disponibili |

Composizione chimica (tipico, in p.p.)

| Elemento | C | - Sì. | M | P | S | Cr | Ni | N | Ti |

|---|---|---|---|---|---|---|---|---|---|

| Max/intervallo | ≤ 0.03 | ≤ 1.0 | ≤ 1.0 | ≤ 0.04 | ≤ 0.03 | 17.019.0 | ≤ 0.5 | ≤ 0.04 | ≥ 0,2 + 4 ((C+N); ≤ 1.10 |

Proprietà meccaniche (condizione di annelamento)

| Immobili | Valore tipico |

|---|---|

| Resistenza alla trazione | 450 ∼ 600 MPa |

| Forza del rendimento (0,2% di compensazione) | ≥ 280 MPa |

| L'allungamento | ≥ 25% (in 50 mm) |

| Durezza (HRB) | ≤ 88 |

| Densità | 70,70 g/cm3 |

| Distanza di fusione | ¥1425 ¥1510°C |

Applicazioni nei sistemi di scarico automobilistici

- Manifold di scarico

Resiste alla stanchezza termica e alla scalabilità a temperature elevate. - Casche per convertitori catalizzati

Mantiene l'integrità strutturale sotto elevato calore e esposizione chimica continua. - Muffler e risonatori

Combatte la corrosione interna da condensato e sale stradale esterno. - Tubi di scarico e tubi intermedi

Offre durabilità estetica e resistenza alla ruggine a lungo termine.

Vantaggi rispetto ai gradi concorrenti

| Caratteristica | Classe 439 | Grado 409 | Grado 430 | Classe 304 |

|---|---|---|---|---|

| Cromo (%) | 17 ¢19 | 10.5 ¢ 11.75 | 16 ¢ 18 | 18 ¢ 20 |

| Stabilizzato (Ti/Nb) | Sì (Ti) | Sì (Ti) | - No, no. | No (salvo 321) |

| Temperatura di servizio massima (°C) | ¥800 | ¥650 | ¥ 700 | ¥870 |

| Resistenza alla corrosione | Eccellente. | Moderato | - Bene. | Eccellente. |

| Efficienza dei costi | Altezza | Molto elevato | Altezza | Basso |

| Saldabilità | - Bene. | - Bene. | Giusto. | Eccellente. |

Produzione e garanzia della qualità

- Test ad ultrasuoni (facoltativo per applicazioni critiche)

- Ispezione superficiale mediante sistemi di visione automatizzati

- Controllo della precisione dimensionale (tolleranza di spessore ± 0,02 mm)

- Rapporti completi di prova di mulino (MTR) con dati chimici e meccanici

Imballaggio e logistica

- I fogli sono intrecciati con carta antirrottatura

- Le bobine sono avvolte in pellicola impermeabile VCI e fissate su pallet di ferro

- Imballaggi pronti all'esportazione conformi alle norme ISO e ai requisiti specifici del cliente

- Spedizione globale su FOB, CIF o EXW

Benefici ambientali e di sostenibilità

- 100% riciclabile: l'acciaio inossidabile conserva il suo valore alla fine della sua vita

- Potenziale di leggerezza: calibri più sottili (ad esempio, 0,8×1,2 mm) riducono il peso del veicolo, migliorando il risparmio di carburante

- Lunga durata di vita: riduce la frequenza di sostituzione e il consumo di risorse

Supporto tecnico e personalizzazione

- Consultazione sulla selezione dei materiali

- Sostegno allo sviluppo di prototipi

- Spessori, larghezze e finiture superficiali su misura

- Servizi di taglio, taglio e spazzatura a laser

Conclusioni