-

Raian IonescuMaterielle Qualität sehr gut. wir haben, zusammenzuarbeiten mehr als 10 Jahre. Sie handeln Losarten des Stahlmaterials. Alle materielle Qualitätsware. Sie Aufgabe für alle materielle Qualität. Wir planieren fortzufahren, mit ihnen in der Zukunft zusammenzuarbeiten

Raian IonescuMaterielle Qualität sehr gut. wir haben, zusammenzuarbeiten mehr als 10 Jahre. Sie handeln Losarten des Stahlmaterials. Alle materielle Qualitätsware. Sie Aufgabe für alle materielle Qualität. Wir planieren fortzufahren, mit ihnen in der Zukunft zusammenzuarbeiten

Stahlplattendicke 0,8 - 10,0 mm für Automobilabgassysteme

| Herkunftsort | China |

|---|---|

| Markenname | TISCO |

| Zertifizierung | ISO |

| Modellnummer | 439 |

| Min Bestellmenge | 500 kg |

| Preis | 1.5 - 2USD/Kg |

| Verpackung Informationen | Standardverpackung für den Exportieren |

| Lieferzeit | 5 - 12 Tage basierend auf der Menge |

| Zahlungsbedingungen | L/C, T/T, Western Union |

| Versorgungsmaterial-Fähigkeit | 20ton pro Woche |

| Produkte | Edelstahlblech | Grad | 439 |

|---|---|---|---|

| Dicke | 0,5 - 10,0 | Technik | Kalt gerollt |

| Breite | 1219mm | Oberfläche | 2B 2D Nr. 1 |

| Standard | ASTM GB JIS EN-LÄRM | Mindestbestellmenge | 1 Tonne |

| Hervorheben | Bleche aus rostfreiem Stahl der Klasse 439,mit einer Breite von mehr als 20 mm,0.8-10.0mm stainless steel sheet |

||

Edelstahlblech Güte 439 Stärke 0,8 - 10,0 mm für Automobil-Auspuffanlagen

Spezifikationen für Edelstahlplatten

| Name | 439 Edelstahlplatte |

| Unsere Güte |

200er Serie: 201 202 300er Serie: 301 304,304L,304H,309S,310S,314,316L,316Ti,316H,316LN,317L,321,329,347 400er Serie: 409L,410,410S,415,416,420,430,431,436L.439,441,443,444,445,446 Super-Edelstahl: 904L,926,254SMO,654SMO,15-5PH,17-4PH,17-7PH.etc Nickellegierung: C276, C22,G35,Alloy X,Monel 400,K500,Inconel 600,601,617,625,718,Incoloy 800,800H,800HT,825.etc |

| Technik | Warmgewalzt, Kaltgewalzt, Geschmiedet |

| Standard | JIS, AISI, ASTM, DIN, TÜV, BV, SUS, etc. |

| Dicke | 0,1 – 80,0 mm |

| Breitenbereich | 10 mm – 2000 mm |

| Länge | Kundenspezifisch |

| Oberfläche | 2B, 2D, NO.1, BA, No.4, 8k, Gebürstet, Hairline, PVD-Beschichtung, Sandgestrahlt |

| Service | Laserschneiden, Biegen |

| Muster | Verfügbar |

Produktübersicht

Warum Güte 439 für Automobil-Auspuffanlagen wählen?

- Kontinuierliche Exposition gegenüber hohen Temperaturen (bis zu 800°C / 1472°F)

- Kondensation von sauren Kondensaten (z. B. Schwefel- und Salpetersäure)

- Thermische Ermüdung durch wiederholte Heiz-/Kühlzyklen

- Streusalz und Umweltverschmutzung

- Stabilisierung mit Titan (Ti): Verhindert Sensibilisierung während des Schweißens und der Hochtemperaturbelastung durch Bindung von Kohlenstoff und Stickstoff, wodurch die Ausscheidung von Chromkarbiden minimiert wird.

- Geringer Kohlenstoff- und Stickstoffgehalt: Verbessert die Schweißbarkeit und die interkristalline Korrosionsbeständigkeit.

- Chromgehalt von 17–19%: Bietet eine robuste passive Oxidschichtbildung zum Korrosionsschutz.

- Ferritische Struktur: Bietet eine gute Wärmeleitfähigkeit und eine geringere Wärmeausdehnung als austenitische Güten (z. B. 304), wodurch Verformungen reduziert werden.

Wichtige Spezifikationen

| Eigenschaft | Wert / Bereich |

|---|---|

| Güte | UNS S43035 / ASTM 439 / EN 1.4510 |

| Dicke | 0,8 mm – 10,0 mm |

| Breite | 600 mm – 2000 mm (anpassbar) |

| Länge | Nach Kundenwunsch (Coils oder Bleche in Zuschnitten) |

| Oberflächenausführung | 2B, BA (hellgeglüht), No.1, Hairline oder kundenspezifisch |

| Standards | ASTM A240, EN 10088-2, JIS G4305, GB/T 4237 |

| Lieferzustand | Geglüht & gebeizt, kaltgewalzt |

| Zertifizierungen | ISO 9001, IATF 16949 (Qualitätsmanagement für die Automobilindustrie), RoHS, Materialprüfberichte (MTR) verfügbar |

Chemische Zusammensetzung (typisch, Gew.-%)

| Element | C | Si | Mn | P | S | Cr | Ni | N | Ti |

|---|---|---|---|---|---|---|---|---|---|

| Max/Bereich | ≤0,03 | ≤1,0 | ≤1,0 | ≤0,04 | ≤0,03 | 17,0–19,0 | ≤0,5 | ≤0,04 | ≥0,2 + 4(C+N); ≤1,10 |

Mechanische Eigenschaften (geglühter Zustand)

| Eigenschaft | Typischer Wert |

|---|---|

| Zugfestigkeit | 450–600 MPa |

| Streckgrenze (0,2 % Dehnung) | ≥280 MPa |

| Dehnung | ≥25 % (in 50 mm) |

| Härte (HRB) | ≤88 |

| Dichte | 7,70 g/cm³ |

| Schmelzbereich | ~1425–1510°C |

Anwendungen in Automobil-Auspuffanlagen

- Auspuffkrümmer

Beständig gegen thermische Ermüdung und Zunderbildung bei erhöhten Temperaturen. - Katalysatorgehäuse

Behält die strukturelle Integrität unter kontinuierlicher Hitze- und Chemikalienbelastung bei. - Schalldämpfer & Resonatoren

Bekämpft innere Korrosion durch Kondensat und äußeres Streusalz. - Endrohre & Zwischenrohre

Bietet ästhetische Haltbarkeit und langfristige Rostbeständigkeit.

Vorteile gegenüber konkurrierenden Güten

| Merkmal | Güte 439 | Güte 409 | Güte 430 | Güte 304 |

|---|---|---|---|---|

| Chrom (%) | 17–19 | 10,5–11,75 | 16–18 | 18–20 |

| Stabilisiert (Ti/Nb) | Ja (Ti) | Ja (Ti) | Nein | Nein (es sei denn 321) |

| Max. Betriebstemperatur (°C) | ~800 | ~650 | ~700 | ~870 |

| Korrosionsbeständigkeit | Ausgezeichnet | Moderat | Gut | Ausgezeichnet |

| Kosteneffizienz | Hoch | Sehr hoch | Hoch | Niedrig |

| Schweißbarkeit | Gut | Gut | Mäßig | Ausgezeichnet |

Herstellung & Qualitätssicherung

- Ultraschallprüfung (optional für kritische Anwendungen)

- Oberflächeninspektion über automatisierte Bildverarbeitungssysteme

- Genauigkeitskontrolle der Abmessungen (Toleranz von ±0,02 mm auf die Dicke)

- Vollständige Werksprüfzeugnisse (MTRs) mit chemischen und mechanischen Daten

Verpackung & Logistik

- Bleche werden mit kratzfestem Papier zwischengelegt

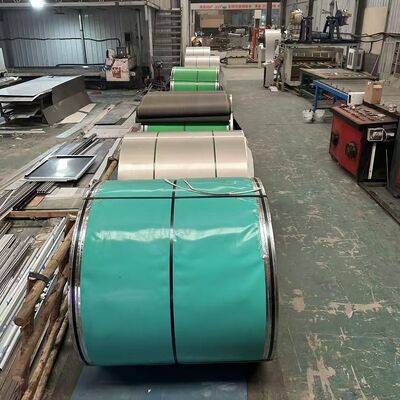

- Coils werden in wasserdichte VCI-Folie gewickelt und auf Eisenpaletten gesichert

- Exportfertige Verpackung gemäß ISO- und kundenspezifischen Anforderungen

- Weltweiter Versand über FOB-, CIF- oder EXW-Bedingungen

Umwelt- & Nachhaltigkeitsvorteile

- 100 % recycelbar: Edelstahl behält seinen Wert am Ende der Lebensdauer

- Leichtbaupotenzial: Geringere Stärken (z. B. 0,8–1,2 mm) reduzieren das Fahrzeuggewicht und verbessern den Kraftstoffverbrauch

- Lange Lebensdauer: Reduziert die Austauschhäufigkeit und den Ressourcenverbrauch

Technische Unterstützung & Anpassung

- Beratung zur Materialauswahl

- Unterstützung bei der Prototypenentwicklung

- Kundenspezifische Stärken, Breiten und Oberflächenausführungen

- Laserschneiden, Spalten und Zuschneiden

Fazit