-

Striscia di acciaio inossidabile

-

Strato di acciaio inossidabile

-

Piatto di acciaio inossidabile

-

tubo di acciaio inossidabile

-

Acciaio inossidabile Antivari

-

Bobina d'acciaio galvanizzata

-

Piatto d'acciaio

-

tondino d'acciaio

-

lega di nichel

-

Tubo d'acciaio senza cuciture

-

Fascio di acciaio inossidabile

-

Strato del piatto di rame

-

Tondino di rame

-

Raian IonescuQualità materiale molto buona. abbiamo cooperare più di 10 anni. Vendono i generi dei lotti di materiale d'acciaio. Tutta la qualità materiale buona. Essi dovere per tutta la qualità materiale. Stiamo spianando per continuare a cooperare in futuro con loro

Raian IonescuQualità materiale molto buona. abbiamo cooperare più di 10 anni. Vendono i generi dei lotti di materiale d'acciaio. Tutta la qualità materiale buona. Essi dovere per tutta la qualità materiale. Stiamo spianando per continuare a cooperare in futuro con loro

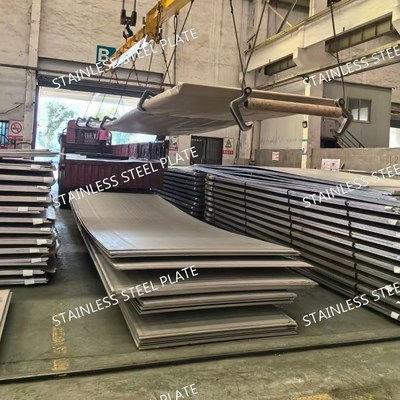

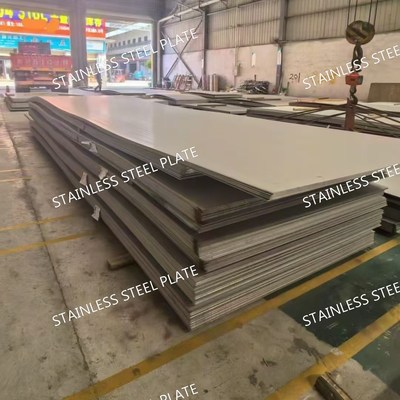

Lamiera in acciaio inossidabile 904L Acciaio legato ad alta resistenza alla corrosione per uso industriale

| Luogo di origine | Cina |

|---|---|

| Marca | BAOSTEEL TISCO |

| Certificazione | ISO |

| Numero di modello | 904L/N08904 |

| Quantità di ordine minimo | 50 kg |

| Prezzo | 8 - 10 USD/Kg |

| Imballaggi particolari | imballaggio standard per l'esportazione |

| Tempi di consegna | 5 - 12 giorni in base alla quantità |

| Termini di pagamento | L/C, T/T, Western Union |

| Capacità di alimentazione | 20ton a settimana |

| Prodotti | lamiere di acciaio inossidabile | Grado | 904L/N08904 |

|---|---|---|---|

| Spessore | 1,0-80,0 mm | Tecnologia | laminato a freddo, laminato a caldo, forgiato |

| Larghezza | 1000mm 1219mm 1500mm o abitudini come richiesta | Superficie | 2B SEDERE No.1 |

| Standard | BACCANO DELL'EN DI ASTM GB JIS | MOQ | 1 tonnellata |

| Evidenziare | 904l lamiera in acciaio inossidabile,lamiere di acciaio legato resistente alla corrosione,Placca di acciaio inossidabile industriale |

||

Piastra in acciaio inossidabile 904L Acciaio legato ad alta resistenza alla corrosione per uso industriale

Specifiche delle lamiere in acciaio inossidabile

| Nome | Piastra in acciaio inossidabile 904L |

| Il nostro grado |

Serie 200: 201 202 Serie 300: 301 304,304L,304H,309S,310S,314,316L,316Ti,316H,316LN,317L,321,329,347 Serie 400: 409L,410,410S,416,420,430,431,436L.439,441,443,444,445,446 Acciaio inossidabile super: 904L,926,254SMO,654SMO,15-5PH,17-4PH,17-7PH.ecc Lega di nichel: C276, C22,G35,Lega X,Monel 400,K500,Inconel 600,601,617,625,718,Incoloy 800,800H,800HT,825.ecc |

| Tecnica | Laminato a caldo, laminato a freddo, forgiato |

| Standard | JIS, AISI, ASTM, DIN, TUV, BV, SUS, ecc. |

| Spessore | 0,1 – 80,0 mm |

| Gamma di larghezza | 10 mm – 2000 mm |

| Lunghezza | Personalizzato |

| Finitura | 2B, BA, No.4, 8k, Spazzolato, Hairline, Rivestimento PVD, Sabbiato |

| Servizio | Taglio laser, piegatura |

| Campione | Disponibile |

Piastra in acciaio inossidabile 904L Acciaio legato ad alta resistenza alla corrosione per uso industriale

La piastra in acciaio inossidabile 904L è una lega premium, completamente austenitica, progettata per ambienti industriali altamente esigenti in cui sono richieste la massima resistenza alla corrosione, un'eccellente formabilità e una lunga durata. Nota per il suo contenuto di carbonio estremamente basso e la composizione della lega migliorata di nichel, cromo, molibdeno e rame, l'acciaio inossidabile 904L offre prestazioni eccezionali in condizioni acide aggressive, sistemi ricchi di cloruri e ambienti che comunemente causano un rapido degrado negli acciai inossidabili convenzionali.

Di seguito è riportata una panoramica completa del prodotto: struttura, proprietà, applicazioni, specifiche tecniche e dati sulle prestazioni, organizzati sia in testo descrittivo che in tabelle dettagliate per una comprensione più chiara.

1. Panoramica del prodotto

La piastra in acciaio inossidabile 904L (UNS N08904) è un grado austenitico ad alta lega, non stabilizzato, comunemente utilizzato nelle industrie chimiche, petrolchimiche, marine e farmaceutiche. La sua composizione chimica superiore offre un'eccezionale resistenza alla vaiolatura, alla corrosione interstiziale e alla tensocorrosione. L'alto contenuto di nichel e molibdeno migliora significativamente la resistenza agli acidi riducenti come l'acido solforico, rendendo il 904L uno dei pochi acciai inossidabili in grado di resistere ad ambienti acidi aggressivi senza una rapida corrosione.

Questo grado mantiene un'elevata tenacità e duttilità anche a temperature sotto zero, offrendo al contempo un'eccellente saldabilità e lavorabilità. Nelle applicazioni in cui l'acciaio inossidabile 316L o 317L può cedere a causa dell'attacco dei cloruri o delle condizioni acide, il 904L si distingue come la scelta affidabile e duratura.

2. Caratteristiche e vantaggi principali

Eccezionale resistenza alla corrosione

-

Elevata resistenza agli acidi solforico, fosforico e acetico

-

Prestazioni eccellenti in ambienti contenenti cloruri (acqua di mare, sistemi di salamoia, lavorazione del sale)

-

Resistenza superiore alla tensocorrosione rispetto agli acciai inossidabili della serie 300

Composizione ad alta lega

-

Il basso contenuto di carbonio previene la precipitazione di carburi durante la saldatura

-

L'alto contenuto di nichel e molibdeno migliora la resistenza alle condizioni riducenti e alla vaiolatura

-

L'aggiunta di rame migliora le prestazioni nelle applicazioni con acido solforico

Durabilità meccanica

-

Elevata resistenza alla trazione e durata anche a temperature elevate

-

Buona resistenza agli urti

-

La struttura austenitica stabile garantisce tenacità in un ampio intervallo di temperature

Buone proprietà di fabbricazione e saldatura

-

Facile da piegare, arrotolare, tagliare e formare

-

Saldabile con metodi standard (TIG, MIG, SMAW)

-

Generalmente non è richiesto il trattamento termico post-saldatura

3. Composizione chimica

| Elemento | Percentuale (%) |

|---|---|

| Carbonio (C) | ≤ 0,020 |

| Cromo (Cr) | 19,0 – 23,0 |

| Nichel (Ni) | 23,0 – 28,0 |

| Molibdeno (Mo) | 4,0 – 5,0 |

| Rame (Cu) | 1,0 – 2,0 |

| Manganese (Mn) | ≤ 2,0 |

| Silicio (Si) | ≤ 1,0 |

| Zolfo (S) | ≤ 0,035 |

| Fosforo (P) | ≤ 0,045 |

| Ferro (Fe) | Equilibrio |

Questa composizione bilanciata è progettata per offrire una resistenza superiore ai meccanismi di corrosione che comunemente colpiscono le apparecchiature e le infrastrutture industriali.

4. Proprietà meccaniche

| Proprietà | Valore |

|---|---|

| Resistenza alla trazione | ≥ 490 MPa |

| Resistenza allo snervamento | ≥ 220 MPa |

| Allungamento | ≥ 35% |

| Durezza (Brinell) | ≤ 190 HB |

| Densità | 8,0 g/cm³ |

| Intervallo di fusione | 1350–1400°C |

La piastra in acciaio inossidabile 904L è rinomata per le sue prestazioni meccaniche stabili, anche in condizioni estreme come temperature criogeniche o lavorazione chimica ad alta temperatura.

5. Proprietà fisiche

| Proprietà | Valore |

|---|---|

| Modulo di elasticità | 200 GPa |

| Conducibilità termica | 12 W/m·K (a 100°C) |

| Resistività elettrica | 0,94 μΩ·m |

| Coefficiente di dilatazione termica | 15 µm/m·°C (0–100°C) |

Queste caratteristiche supportano un'eccezionale stabilità dimensionale e affidabilità in ambienti critici di precisione.

6. Dimensioni e dimensioni disponibili

È possibile fornire dimensioni personalizzate, lamiere tagliate a misura e componenti lavorati a CNC in base alle esigenze applicative.

| Spessore (mm) | Larghezza (mm) | Lunghezza (mm) | Finitura |

|---|---|---|---|

| 3 – 6 | 1000–2000 | 2000–6000 | 2B / BA |

| 6 – 12 | 1000–2500 | 2000–8000 | No.1 / 2B |

| 12 – 50 | 1500–3000 | 3000–12000 | No.1 |

| > 50 | Personalizzato | Personalizzato | Laminato a caldo |

Le finiture superficiali includono 2B, BA, No.1, No.4, HL (Hairline) e superfici strutturate personalizzate.

7. Applicazioni della piastra in acciaio inossidabile 904L

Grazie all'eccezionale resistenza alla corrosione e alla resistenza meccanica, la piastra in acciaio inossidabile 904L è ampiamente utilizzata in:

Lavorazione chimica e petrolchimica

-

Impianti di produzione di acido solforico

-

Serbatoi di stoccaggio di acido fosforico

-

Reattori di acido acetico

-

Scambiatori di calore, evaporatori, condensatori

Industria marittima

-

Apparecchiature di dissalazione

-

Componenti di piattaforme offshore

-

Elementi strutturali per la costruzione navale

-

Sistemi di raffreddamento ad acqua di mare

Settore petrolifero e del gas

-

Sistemi di tubazioni

-

Apparecchiature di raffineria

-

Sistemi di depurazione dei gas

Lavorazione farmaceutica e alimentare

-

Serbatoi di stoccaggio igienici

-

Tubazioni di processo

-

Apparecchiature di pulizia e sterilizzazione

Apparecchiature ambientali

-

Sistemi di desolforazione dei fumi (FGD)

-

Unità di trattamento delle acque reflue

Ingegneria e architettura di fascia alta

-

Componenti di apparecchiature di lusso

-

Elementi strutturali decorativi esposti ad ambienti esterni aggressivi

8. Prestazioni di resistenza alla corrosione

L'acciaio inossidabile 904L si distingue per la sua maggiore resistenza a:

-

Corrosione per vaiolatura in ambienti ricchi di cloruri

-

Corrosione interstiziale in spazi ristretti

-

Tensocorrosione sotto carico di trazione

-

Corrosione intergranulare a causa del basso contenuto di carbonio

-

Corrosione generale in mezzi acidi

È particolarmente efficace in concentrazioni di acido solforico da basse ad alte, dove gli acciai inossidabili standard si degradano rapidamente. L'aggiunta di rame migliora significativamente questa prestazione.

9. Lavorazione e fabbricazione

Taglio e lavorazione

-

Taglio laser, taglio al plasma e taglio a getto d'acqua

-

Buona lavorabilità con utensili adeguati

Saldatura

-

Compatibile con i processi TIG/MIG/SMAW

-

Si consigliano metalli d'apporto come 904L o leghe ad alto contenuto di nichel

-

Non è necessario il trattamento termico post-saldatura

Formatura e piegatura

-

Elevata duttilità e formabilità grazie alla struttura austenitica

-

Adatto per imbutitura profonda, laminazione, piegatura e stampaggio

10. Imballaggio e consegna

Per proteggere la superficie della lega di alto valore, le piastre in acciaio inossidabile 904L sono confezionate con:

-

Film di avvolgimento impermeabile

-

Carta antiruggine

-

Pallet rinforzati in acciaio o casse di legno

-

Protezioni per bordi in plastica

La spedizione globale è disponibile via mare, aerea o terrestre.

11. Garanzia di qualità

Ogni piastra in acciaio inossidabile 904L è sottoposta a rigorosi test di qualità, tra cui:

-

Analisi della composizione chimica

-

Test delle proprietà meccaniche

-

Ispezione a ULTRASUONI

-

Controllo della rugosità superficiale

-

Verifica dell'accuratezza dimensionale

-

PMI (Identificazione positiva del materiale)

La conformità agli standard internazionali come ASTM B625, ASTM A240, JIS G4304/G4305, EN 1.4539 e le specifiche GB/T garantisce affidabilità e coerenza.

12. Conclusione

La piastra in acciaio inossidabile 904L è la soluzione ideale per le industrie che richiedono una resistenza alla corrosione avanzata, una lunga durata e prestazioni meccaniche eccellenti in condizioni ambientali estreme. Con la sua composizione in lega superiore e l'eccezionale resistenza agli acidi aggressivi e agli ambienti ricchi di cloruri, supera di gran lunga i gradi di acciaio inossidabile convenzionali come 316L o 317L.

Sia che venga utilizzata in sistemi di lavorazione chimica, ingegneria marittima, apparecchiature petrolifere e del gas o applicazioni industriali di elevata purezza, la piastra in acciaio inossidabile 904L offre stabilità, affidabilità e durata senza pari.

![]()

![]()

![]()

![]()