-

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

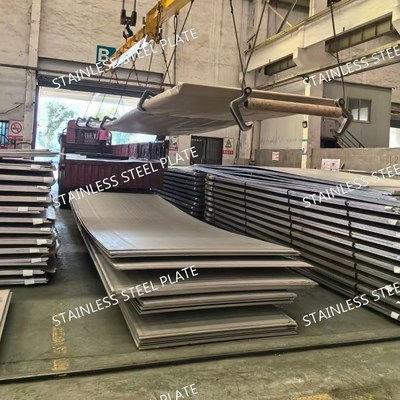

904L 스테인리스강 판재 고내식성 합금강 시트 산업용

| 제품 | 스테인레스 강판 | 등급 | 904L / N08904 |

|---|---|---|---|

| 두께 | 1.0-80.0mm | 기술 | 냉간압연, 열간압연, 단조 |

| 너비 | 1000 밀리미터 1219 밀리미터 1500 밀리미터 또는 요구로서의 세관 | 표면 | 2B BA No.1 |

| 기준 | ASTM GB JIS EN DIN | MOQ | 1톤 |

| 강조하다 | 904l 스테인레스 스틸 판,고성질의 합금강판,산업용 스테인레스 스틸 판 |

||

904L 스테인리스강 판재 고내식성 합금강판 산업용

스테인리스강판 사양

| 이름 | 904L 스테인리스강 판재 |

| 당사 등급 |

200 시리즈: 201 202 300 시리즈: 301 304,304L,304H,309S,310S,314,316L,316Ti,316H,316LN,317L,321,329,347 400 시리즈: 409L,410,410S,416,420,430,431,436L.439,441,443,444,445,446 슈퍼 스테인리스강: 904L,926,254SMO,654SMO,15-5PH,17-4PH,17-7PH 등 니켈 합금: C276, C22,G35,합금 X,Monel 400,K500,Inconel 600,601,617,625,718,Incoloy 800,800H,800HT,825 등 |

| 기술 | 열간 압연, 냉간 압연, 단조 |

| 표준 | JIS, AISI, ASTM, DIN, TUV, BV, SUS 등 |

| 두께 | 0.1 – 80.0mm |

| 폭 범위 | 10mm – 2000mm |

| 길이 | 맞춤형 |

| 마감 | 2B, BA, No.4, 8k, 브러시, 헤어라인, PVD 코팅, 샌드블라스트 |

| 서비스 | 레이저 절단, 벤딩 |

| 샘플 | 사용 가능 |

904L 스테인리스강 판재 고내식성 합금강판 산업용

904L 스테인리스강 판재는 최대 내식성, 뛰어난 성형성 및 장기 내구성이 요구되는 매우 까다로운 산업 환경을 위해 설계된 프리미엄, 완전 오스테나이트계 합금입니다. 매우 낮은 탄소 함량과 니켈, 크롬, 몰리브덴 및 구리의 향상된 합금 조성을 특징으로 하는 904L 스테인리스강은 공격적인 산성 조건, 염화물 풍부 시스템 및 기존 스테인리스강에서 급격한 열화를 유발하는 환경에서 탁월한 성능을 제공합니다.

다음은 더 명확한 이해를 위해 설명 텍스트와 자세한 표로 구성된 포괄적인 제품 개요(구조, 특성, 응용 분야, 기술 사양 및 성능 데이터)입니다.

1. 제품 개요

904L 스테인리스강 판재(UNS N08904)는 화학, 석유화학, 해양 및 제약 산업에서 일반적으로 사용되는 고합금, 비안정화 오스테나이트계 등급입니다. 우수한 화학 조성은 피팅, 틈새 부식 및 응력 부식 균열에 대한 뛰어난 저항성을 제공합니다. 높은 니켈 및 몰리브덴 함량은 황산과 같은 환원산에 대한 저항성을 크게 향상시켜 904L을 급속 부식 없이 가혹한 산성 환경을 견딜 수 있는 몇 안 되는 스테인리스강 중 하나로 만듭니다.

이 등급은 극저온에서도 높은 인성과 연성을 유지하는 동시에 뛰어난 용접성 및 가공성을 제공합니다. 316L 또는 317L 스테인리스강이 염화물 공격 또는 산성 조건으로 인해 실패할 수 있는 응용 분야에서 904L은 신뢰할 수 있고 오래 지속되는 선택으로 두각을 나타냅니다.

2. 주요 특징 및 장점

탁월한 내식성

-

황산, 인산 및 아세트산에 대한 높은 저항성

-

염화물 환경(해수, 염수 시스템, 염 처리)에서 우수한 성능

-

300 시리즈 스테인리스강에 비해 응력 부식 균열에 대한 우수한 저항성

고합금 조성

-

낮은 탄소 함량은 용접 중 탄화물 석출을 방지합니다.

-

높은 니켈 및 몰리브덴은 환원 및 피팅 조건에 대한 저항성을 향상시킵니다.

-

구리 첨가는 황산 응용 분야에서 성능을 향상시킵니다.

기계적 내구성

-

고온에서도 높은 인장 강도와 내구성

-

우수한 충격 저항성

-

안정적인 오스테나이트 구조는 광범위한 온도 범위에서 인성을 보장합니다.

우수한 제작 및 용접 특성

-

쉽게 구부리고, 압연하고, 절단하고, 성형할 수 있습니다.

-

표준 방법(TIG, MIG, SMAW)으로 용접 가능

-

용접 후 열처리는 일반적으로 필요하지 않습니다.

3. 화학 조성

| 원소 | 백분율(%) |

|---|---|

| 탄소(C) | ≤ 0.020 |

| 크롬(Cr) | 19.0 – 23.0 |

| 니켈(Ni) | 23.0 – 28.0 |

| 몰리브덴(Mo) | 4.0 – 5.0 |

| 구리(Cu) | 1.0 – 2.0 |

| 망간(Mn) | ≤ 2.0 |

| 규소(Si) | ≤ 1.0 |

| 황(S) | ≤ 0.035 |

| 인(P) | ≤ 0.045 |

| 철(Fe) | 나머지 |

이 균형 잡힌 조성은 산업 장비 및 인프라에 일반적으로 영향을 미치는 부식 메커니즘에 대한 우수한 저항성을 제공하도록 설계되었습니다.

4. 기계적 특성

| 특성 | 값 |

|---|---|

| 인장 강도 | ≥ 490 MPa |

| 항복 강도 | ≥ 220 MPa |

| 신율 | ≥ 35% |

| 경도(브리넬) | ≤ 190 HB |

| 밀도 | 8.0 g/cm³ |

| 융점 범위 | 1350–1400°C |

904L 스테인리스강 판재는 극저온 또는 고온 화학 처리와 같은 극한 조건에서도 안정적인 기계적 성능으로 유명합니다.

5. 물리적 특성

| 특성 | 값 |

|---|---|

| 탄성 계수 | 200 GPa |

| 열전도율 | 12 W/m·K (100°C에서) |

| 전기 저항 | 0.94 μΩ·m |

| 열팽창 계수 | 15 µm/m·°C (0–100°C) |

이러한 특성은 정밀도가 중요한 환경에서 뛰어난 치수 안정성과 신뢰성을 지원합니다.

6. 사용 가능한 크기 및 치수

응용 분야 요구 사항에 따라 맞춤형 크기, 절단 길이 시트 및 CNC 가공 부품을 제공할 수 있습니다.

| 두께(mm) | 폭(mm) | 길이(mm) | 마감 |

|---|---|---|---|

| 3 – 6 | 1000–2000 | 2000–6000 | 2B / BA |

| 6 – 12 | 1000–2500 | 2000–8000 | No.1 / 2B |

| 12 – 50 | 1500–3000 | 3000–12000 | No.1 |

| > 50 | 맞춤형 | 맞춤형 | 열간 압연 |

표면 마감에는 2B, BA, No.1, No.4, HL(헤어라인) 및 맞춤형 질감 표면이 포함됩니다.

7. 904L 스테인리스강 판재의 응용 분야

뛰어난 내식성과 기계적 강도 덕분에 904L 스테인리스강 판재는 다음과 같은 분야에서 널리 사용됩니다.

화학 및 석유화학 처리

-

황산 생산 공장

-

인산 저장 탱크

-

아세트산 반응기

-

열교환기, 증발기, 응축기

해양 산업

-

담수화 장비

-

해양 플랫폼 구성 요소

-

조선 구조 요소

-

해수 냉각 시스템

석유 및 가스 부문

-

파이프라인 시스템

-

정유 장비

-

가스 세정 시스템

제약 및 식품 가공

-

위생 저장 탱크

-

공정 배관

-

세척 및 살균 장비

환경 장비

-

배연 탈황(FGD) 시스템

-

폐수 처리 장치

고급 엔지니어링 및 건축

-

고급 장비 구성 요소

-

공격적인 실외 환경에 노출된 장식 구조 요소

8. 내식성 성능

904L 스테인리스강은 다음과 같은 향상된 저항성으로 두각을 나타냅니다.

-

피팅 부식 염화물 풍부 환경에서

-

틈새 부식 좁은 공간에서

-

응력 부식 균열 인장 하중 하에서

-

입계 부식 낮은 탄소 함량으로 인해

-

일반 부식 산성 매체에서

표준 스테인리스강이 빠르게 열화되는 낮은 농도에서 높은 농도까지의 황산에서 특히 효과적입니다. 구리 첨가는 이 성능을 크게 향상시킵니다.

9. 가공 및 제작

절단 및 가공

-

레이저 절단, 플라즈마 절단 및 워터젯 절단

-

적절한 공구로 우수한 가공성

용접

-

TIG/MIG/SMAW 공정과 호환

-

904L 또는 고니켈 합금과 같은 필러 금속 권장

-

용접 후 열처리 불필요

성형 및 벤딩

-

오스테나이트 구조로 인한 높은 연성 및 성형성

-

딥 드로잉, 압연, 접기 및 스탬핑에 적합

10. 포장 및 배송

고가 합금 표면을 보호하기 위해 904L 스테인리스강 판재는 다음과 같이 포장됩니다.

-

방수 포장 필름

-

방청지

-

강철 보강 팔레트 또는 나무 상자

-

플라스틱 가장자리 보호대

해상, 항공 또는 육로를 통한 글로벌 배송 가능

11. 품질 보증

각 904L 스테인리스강 판재는 다음과 같은 엄격한 품질 테스트를 거칩니다.

-

화학 조성 분석

-

기계적 특성 테스트

-

초음파 검사

-

표면 조도 제어

-

치수 정확도 확인

-

PMI(재료 긍정 식별)

ASTM B625, ASTM A240, JIS G4304/G4305, EN 1.4539 및 GB/T 사양과 같은 국제 표준 준수는 신뢰성과 일관성을 보장합니다.

12. 결론

904L 스테인리스강 판재는 극한의 환경 조건에서 고급 내식성, 장기 내구성 및 우수한 기계적 성능이 필요한 산업에 이상적인 솔루션입니다. 우수한 합금 조성과 공격적인 산 및 염화물 풍부 환경에 대한 탁월한 저항성으로 316L 또는 317L과 같은 기존 스테인리스강 등급보다 훨씬 뛰어난 성능을 발휘합니다.

화학 처리 시스템, 해양 공학, 석유 및 가스 장비 또는 고순도 산업 응용 분야에 사용되든 904L 스테인리스강 판재는 비교할 수 없는 안정성, 신뢰성 및 수명을 제공합니다.

![]()

![]()

![]()

![]()