Όλα τα Προϊόντα

-

Raian IonescuΥλική ποιότητα πολύ υψηλή. πρέπει να συνεργαστούμε περισσότερο από 10 έτη. Ανταλλάσσουν τα είδη μερών υλικού χάλυβα. Όλο το υλικό ποιοτικό αγαθό. Αυτοί δασμός για όλη την υλική ποιότητα. Πλανίζουμε συνεχιζόμαστε συνεργαζόμαστε με τους στο μέλλον

Raian IonescuΥλική ποιότητα πολύ υψηλή. πρέπει να συνεργαστούμε περισσότερο από 10 έτη. Ανταλλάσσουν τα είδη μερών υλικού χάλυβα. Όλο το υλικό ποιοτικό αγαθό. Αυτοί δασμός για όλη την υλική ποιότητα. Πλανίζουμε συνεχιζόμαστε συνεργαζόμαστε με τους στο μέλλον

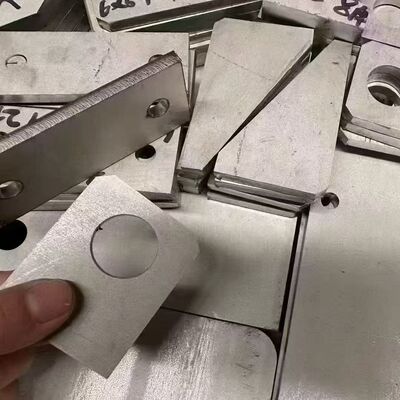

Laser Cutting Duplex 2205 2507 Stainless Steel Plate Hot Rolled Thickness 3.0 - 40.0mm

| Τόπος καταγωγής | Κίνα |

|---|---|

| Μάρκα | DELTA |

| Πιστοποίηση | ISO |

| Αριθμό μοντέλου | 2205 2507 |

| Ποσότητα παραγγελίας min | 500 κιλά |

| Τιμή | 3200 - 3600 USD/Ton |

| Συσκευασία λεπτομέρειες | ξύλινες παλέτες + αδιάβροχο χαρτί |

| Χρόνος παράδοσης | 5 - 12 ημέρες με βάση την ποσότητα |

| Όροι πληρωμής | L/C, T/T, Western Union |

| Δυνατότητα προσφοράς | 5 τόνοι την εβδομάδα |

Με ελάτε σε επαφή με δωρεάν δείγματα και δελτία.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Εάν έχετε οποιαδήποτε ανησυχία, παρέχουμε τη 24ωρη σε απευθείας σύνδεση βοήθεια.

xΛεπτομέρειες

| Προϊόντα | πλάκα από ανοξείδωτο χάλυβα | Βαθμός | 2205 2507 |

|---|---|---|---|

| Τυπικό μέγεθος | 1500*6000mm | Πάχος | 2,0 - 40,0 mm |

| Μάρκα | TISCO BAOSTEEL POSCO LISCO | Λιμάνι φόρτωσης | Λιμάνι της Σαγκάης |

| MOQ | 500 κιλά | Συσκευασία | ξύλινες παλέτες + αδιάβροχο χαρτί |

| Επισημαίνω | Laser cutting duplex 2205 stainless steel plate,Hot rolled 2507 stainless steel plate,Stainless steel plate thickness 3.0-40.0mm |

||

Περιγραφή προϊόντων

Laser Cutting Duplex 2205 2507 Stainless Steel Plate Hot Rolled Thickness 3.0 - 40.0mm

Products Specification

| Products | Duplex Stainless Steel Plate |

| Thickness | 1.0- 40.0mm |

| Width | 1000mm 1219mm 1500mm 1800mm 2000mm or other width as request |

| Length | 2000mm 2438mm 3000mm 6000mm or other length as request |

| Grade | 201 202 301 304 304L 304H 309S 310S 316L 316Ti 317L 321 347 409L 410 420 430 431 436L 439 441 443 444 2205 2507 904L 600 625 800 825 718 253MA 254SMO.etc |

| Service | Laser Cutting, Surface processing, bending |

| Brand | TISCO BAOSTEEL POSCO LISCO JISCO |

| Standard | ASTM JIS GB DIN EN BS |

| Certificate | ISO MTC C/O F/E |

| Packing | Wooden pallets and waterproof paper |

| Deliver time | 5 - 15 days |

| Loading port | Shanghai Port |

Laser Cutting Duplex 2205 & 2507 Stainless Steel Plate – Hot Rolled, Thickness 3.0–40.0mm

Overview

Duplex stainless steels have become indispensable in demanding industrial environments where high strength, excellent corrosion resistance, and cost-efficiency are critical. Among the most widely used grades are Duplex 2205 (UNS S32205/S31803) and Super Duplex 2507 (UNS S32750). These alloys combine the best attributes of austenitic and ferritic stainless steels—offering roughly twice the yield strength of standard austenitic grades like 304 or 316, along with superior resistance to stress corrosion cracking, pitting, and crevice corrosion—especially in chloride-rich environments.

Our laser-cut Duplex 2205 and 2507 hot-rolled stainless steel plates, available in thicknesses from 3.0 mm to 40.0 mm, are engineered for precision applications across oil & gas, chemical processing, marine engineering, desalination plants, and offshore platforms. With advanced CNC laser cutting capabilities, we deliver components with tight tolerances, smooth edges, and minimal heat-affected zones—ensuring structural integrity and performance in harsh service conditions.

Why Choose Laser-Cut Duplex Stainless Steel Plates?

Laser cutting offers unmatched precision, repeatability, and edge quality for duplex stainless steel. Unlike plasma or flame cutting, fiber laser technology minimizes thermal distortion and oxidation, preserving the material’s dual-phase microstructure (approximately 50% austenite + 50% ferrite)—which is essential for maintaining mechanical and corrosion-resistant properties.

Key advantages include:

- High dimensional accuracy (±0.1 mm tolerance achievable)

- Clean, burr-free edges requiring little to no post-processing

- Complex geometries without tooling costs

- Material efficiency through optimized nesting software

- Preservation of corrosion resistance due to controlled heat input

Material Comparison: Duplex 2205 vs. Super Duplex 2507

| Property | Duplex 2205 (S32205/S31803) | Super Duplex 2507 (S32750) |

|---|---|---|

| Composition (Typical wt%) | Cr: 22%, Ni: 5.5%, Mo: 3.2%, N: 0.17% | Cr: 25%, Ni: 7%, Mo: 4%, N: 0.28% |

| PREN (Pitting Resistance Equivalent Number)* | 34–38 | 40–45 |

| Yield Strength (Rp0.2) | ≥450 MPa | ≥550 MPa |

| Tensile Strength (Rm) | 620–750 MPa | 750–950 MPa |

| Elongation at Break | ≥25% | ≥25% |

| Max Service Temp (Continuous) | ~300°C | ~280°C |

| Chloride SCC Resistance | Excellent (2–3× better than 316L) | Exceptional (2× better than 2205) |

| Common Applications | Chemical tanks, heat exchangers, pipelines | Offshore risers, seawater systems, FGD scrubbers |

*PREN = %Cr + 3.3×%Mo + 16×%N — higher values indicate greater pitting resistance.

Product Specifications

| Feature | Details |

|---|---|

| Material Grades | Duplex 2205 (UNS S32205 / S31803), Super Duplex 2507 (UNS S32750) |

| Form | Hot-rolled plate (as-rolled or pickled & passivated upon request) |

| Thickness Range | 3.0 mm to 40.0 mm |

| Standard Sizes | 2000×6000 mm, 2500×6000 mm (custom sizes available) |

| Surface Finish | Hot-rolled mill finish (Ra ~6.3–12.5 µm); optional pickling for improved corrosion resistance |

| Certifications | EN 10217-7, ASTM A240/A240M, NORSOK M-650 (for 2507), Mill Test Reports (EN 10204 3.1/3.2) |

| Laser Cutting Capability | Fiber laser up to 25 mm; CO₂ laser for thicker sections (up to 40 mm) |

| Tolerances (Cut Parts) | ±0.1 mm (for <10 mm), ±0.2 mm (10–25 mm), ±0.5 mm (>25 mm) |

| Edge Quality | ISO 9013 Class 2–3 (smooth, dross-free) |

Performance Advantages in Critical Environments

1. Resistance to Chloride Stress Corrosion Cracking (SCC)

Both 2205 and 2507 excel where standard austenitic steels fail. In seawater, brine, or chemical processing plants with chlorides >1000 ppm, 2205 provides reliable service up to 60–80°C. For more aggressive conditions (e.g., >80°C or higher chloride concentrations), 2507 is preferred due to its higher chromium, molybdenum, and nitrogen content.

2. High Strength-to-Weight Ratio

With yield strengths nearly double that of 316L, duplex plates allow for thinner designs, reducing weight and material costs—especially valuable in offshore platforms and pressure vessels.

3. Thermal & Mechanical Stability

The balanced ferritic-austenitic structure ensures good toughness down to -50°C and stable performance under cyclic loading—ideal for dynamic marine or subsea applications.

Laser Cutting Process Considerations

Cutting duplex stainless steel requires optimized parameters to avoid:

- Excessive heat input, which can form harmful intermetallic phases (e.g., sigma phase) above 300°C during slow cooling.

- Nitrogen loss in the cut zone, potentially reducing local corrosion resistance.

Our process includes:

- High-pressure nitrogen assist gas to prevent oxide formation and maintain clean edges.

- Controlled cutting speeds to limit heat accumulation.

- Post-cut inspection via visual and dye-penetrant testing for critical applications.

For thicknesses >25 mm, we recommend stress-relief annealing at 1020–1100°C followed by rapid quenching if the part will be used in highly corrosive environments—though this is rarely needed for laser-cut components due to minimal HAZ.

Typical Applications

| Industry | Application Examples |

|---|---|

| Oil & Gas | Subsea manifolds, flowlines, Christmas trees, separators |

| Chemical Processing | Reactors, storage tanks, piping systems handling acids/chlorides |

| Marine & Offshore | Seawater piping, ballast systems, FPSO components |

| Desalination | High-pressure reverse osmosis membranes, brine heaters |

| Pulp & Paper | Digesters, bleach towers, recovery boilers |

| Power Generation | Flue gas desulfurization (FGD) ducts, heat exchangers |

Ordering Information

We supply laser-cut parts or full plates based on your CAD drawings (DXF, DWG, STEP). Minimum order quantity: 1 piece. Lead time: 5–15 working days depending on complexity and volume.

Available Finishes:

- As-cut (standard)

- Pickled & passivated (enhanced corrosion resistance)

- Beveled edges (for welding prep)

Quality Assurance:

- Full traceability via heat number

- PMI (Positive Material Identification) available

- Ultrasonic testing (UT) for plates >20 mm upon request

Sustainability & Lifecycle Value

Duplex stainless steels offer long service life with minimal maintenance—reducing downtime and replacement costs. Their high recyclability (>90%) aligns with circular economy principles. While initial material cost is higher than 316L, the total cost of ownership is often lower due to extended lifespan and reduced wall thickness requirements.

Conclusion

Whether you need cost-effective corrosion resistance (2205) or maximum performance in extreme environments (2507), our laser-cut hot-rolled duplex stainless steel plates deliver precision, reliability, and engineering value. Backed by stringent quality control and global material standards, these products are trusted by leading EPC contractors and OEMs worldwide.

laser cut duplex stainless steel plate, 2205 stainless steel laser cutting, 2507 super duplex plate, hot rolled duplex steel 3mm to 40mm, PREN 40 stainless steel, chloride resistant steel plate, CNC laser cut 2205, offshore grade stainless steel, high strength corrosion resistant plate, S32750 laser cutting service.

Συνιστώμενα προϊόντα