-

Tira de acero inoxidable

-

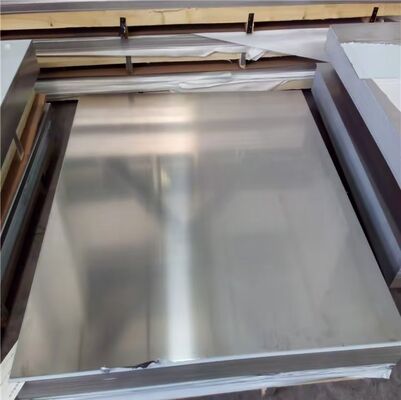

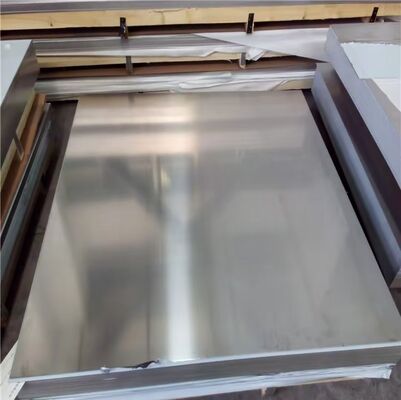

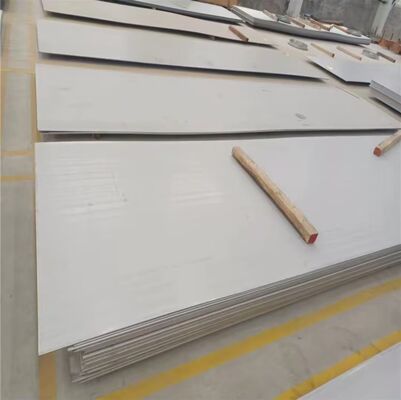

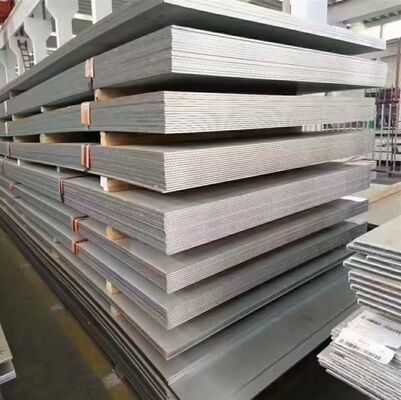

Hoja de acero inoxidable

-

Placa de acero inoxidable

-

tubería de acero inoxidable

-

Barra de acero inoxidable

-

Bobina de acero galvanizada

-

Placa de acero

-

barra redonda de acero

-

aleación de níquel

-

Tubería de acero inconsútil

-

Haz de acero inoxidable

-

Hoja de la placa de cobre

-

Barra redonda de cobre

-

Raian IonescuCalidad material muy buena. tenemos cooperar más de 10 años. Negocian clases de las porciones de material de acero. Toda la calidad material buena. Ellos deber para toda la calidad material. Estamos acepillando para continuar cooperando con ellos en el futuro

Raian IonescuCalidad material muy buena. tenemos cooperar más de 10 años. Negocian clases de las porciones de material de acero. Toda la calidad material buena. Ellos deber para toda la calidad material. Estamos acepillando para continuar cooperando con ellos en el futuro

Hoja de acero inoxidable 439 laminada con precisión y optimizada para su resistencia al calor y durabilidad

| Lugar de origen | Porcelana |

|---|---|

| Nombre de la marca | TISCO |

| Certificación | ISO |

| Número de modelo | 439 |

| Cantidad de orden mínima | 500 kgs |

| Precio | 1.5 - 2USD/Kg |

| Detalles de empaquetado | Embalaje estándar para la exportación |

| Tiempo de entrega | 5 - 12 días basado en la cantidad |

| Condiciones de pago | LC, T/T, Western Union |

| Capacidad de la fuente | 20ton por semana |

| productos | Hoja de acero inoxidable | Calificación | 439 |

|---|---|---|---|

| Espesor | 0,5 - 10,0 | Técnico | Enrollado |

| Ancho | 1219m m | Superficie | 2B 2D NO.1 |

| Estándar | ESTRUENDO DEL EN DE ASTM GB JIS | Cantidad mínima de pedido | 1 tonelada |

| Resaltar | 439 chapa de acero inoxidable resistente al calor,de acero inoxidable laminado con precisión,hojas de acero inoxidable duraderas 439 |

||

Hoja de acero inoxidable 439 laminada con precisión y optimizada para su resistencia al calor y durabilidad

Especificaciones de las placas de acero inoxidable

| Nombre | 439 Acero inoxidable |

| Nuestra calificación |

Sección 200: 201 202 La serie 300: 301 304, 304 L, 304 H, 309 S, 310 S,314- 316L 316Ti 316H 316LN 317L321,329,347 Serie 400: 409L,410,410S,415,416,420,430,431- ¿Qué es eso?439,441,443,444,445,446 El acero inoxidable super: 904L,926,254SMO,654SMO,15-5PH,17-4PH,17-7PH,etc En el caso de los productos que no estén sujetos a restricciones de los requisitos de seguridad, la autoridad competente podrá decidir que los productos que no estén sujetos a restricciones de seguridad no cumplan los requisitos de seguridad establecidos en el anexo II.601,617,625,718Incoloy 800,800H,800HT,825.etc. |

| Técnica | Rollado en caliente, laminado en frío, forjado |

| Estándar | El valor de las emisiones de gases de efecto invernadero es el valor de las emisiones de gases de efecto invernadero, que es el valor de las emisiones de gases de efecto invernadero. |

| El grosor | 0.1 80 mm |

| Rango de ancho | 10 mm 2000 mm |

| Duración | Personalizado |

| Acaba. | 2B, 2D, no.1No, BA, no4, 8k, cepillado, línea del cabello, revestimiento PVD, chorro de arena |

| Servicio | Cortar con láser y doblar |

| Muestra | Disponible |

Resumen del producto

Por qué importa el rodamiento preciso

- Reducción en frío de varios pasos con espacios de rodadura controlados por ordenador

- Anulación continua en atmósferas de hidrógeno-nitrógeno para suavidad y limpieza

- Limpieza y decapado electrolítico de superficies libres de óxidos

- Medición por láser en línea para el seguimiento del grosor en tiempo real

Diseñados para condiciones extremas

Estable hasta 800 °C (1472 °F) debido a una capa Cr2O3 densa y autocurante que resiste la escamación y la espallación.

El Ti se une al carbono y al nitrógeno, evitando el agotamiento del cromo en los límites del grano, eliminando la corrosión intergranular después de la soldadura o la exposición prolongada a altas temperaturas.

La estructura ferrítica ofrece una expansión un 30% más baja que los grados austeníticos, reduciendo la deformación y la fatiga articular en aplicaciones de calefacción cíclica.

Resiste el agujero de la sal de carretera, los condensados ácidos (H2SO4, HNO3) y los gases de escape ricos en azufre, lo que prolonga la vida útil del componente en 2 × 3 en comparación con el acero suave o el acero inoxidable 409.

A pesar de su resistencia a temperatura, mantiene una elongación >25% para el dibujo profundo, la flexión y la hidroformación sin grietas.

Especificaciones técnicas

| Parámetro | Detalles |

|---|---|

| Grado | Las emisiones de gases de efecto invernadero de los gases de efecto invernadero de los gases de efecto invernadero de los gases de efecto invernadero de los gases de efecto invernadero de los gases de efecto invernadero de los gases de efecto invernadero de los gases de efecto invernadero de los gases de efecto invernadero de los gases de efecto invernadero |

| Formulario | Hojas laminadas en frío de precisión |

| Rango de espesor | 0.8 mm 10.0 mm (tolerancias personalizadas disponibles) |

| Tolerancia estándar | ± 0,02 mm (para 0,8 ∼ 3,0 mm); ± 0,05 mm (para > 3,0 mm) |

| Anchos | 600~2000 mm (estándar); se puede cortar a medida |

| Duración | Cortado a la longitud (por ejemplo, 2438 mm / 8 ft) o en bobina |

| Finalización de la superficie | 2B (estándar), BA, Hairline o especificado por el cliente |

| Las normas | Las medidas de ensayo se aplicarán en el caso de los productos de la categoría A, B, C, D, E, F, G, H o H. |

| Certificaciones | Se proporcionan las normas ISO 9001, IATF 16949, RoHS; EN 10204 3.1 MTR |

Composición química (típica, en peso%)

| El elemento | C. Las | Sí, sí. | En | P | El S | Crónica | ¿ Qué? | No | Ti |

|---|---|---|---|---|---|---|---|---|---|

| Max/rango | ≤ 003 | ≤ 10 | ≤ 10 | ≤ 004 | ≤ 003 | 17.0 ¢19.0 | ≤ 05 | ≤ 004 | ≥ 0,2 + 4 × ((C + N); ≤ 1.10 |

Propiedades mecánicas y físicas (condición de recocido)

| Propiedad | Valor típico |

|---|---|

| Resistencia a la tracción | 450 ∼ 600 MPa |

| Fuerza de rendimiento (0,2% de compensación) | ≥ 280 MPa |

| Elongado | ≥ 25% (en 50 mm) |

| Dureza (HRB) | ≤ 88 años |

| Densidad | 70,70 g/cm3 |

| Conductividad térmica (100 °C) | 26 W/m·K |

| Coeficiente de expansión térmica (20-100°C) | 10.4 × 10−6 /°C |

| Temperatura máxima de funcionamiento continuo | Se trata de un sistema de control de las emisiones. |

Aplicaciones

- Automóviles: colectores de escape, capas de convertidores catalíticos, silenciadores, tubos de escape

- Industriales: tubos de quemadores, conductos de gases de combustión, unidades de recuperación de calor

- Aplicaciones: fornos, depósitos de lavavajillas, tambores de secadores

- Energía: componentes de calderas de biomasa, receptores solares térmicos

Ventajas sobre las calificaciones estándar

| Características | Las demás máquinas y aparatos | El estándar 409 | Las demás materias del capítulo 9 |

|---|---|---|---|

| Tolerancia de espesor | ± 0,02 mm | ±0,10 mm o más | ± 0,20 mm |

| Calidad de la superficie | Limpios, sin defectos | Escala, pozos comunes | Rápido, oxidado |

| Consistencia de la formabilidad | Alto (grano uniforme) | Variable | Los pobres. |

| Rendimiento posterior a la fabricación | > 95 por ciento | El 80% y el 85% | < el 80% |

| Desempeño de alta velocidad | Es excelente. | Moderado | Es justo. |

Proceso de garantía de calidad

- Verificación espectrométrica de la química

- Pruebas de tracción y dureza por lote

- Inspección automatizada de superficies (cámaras CCD detectan microdefectos)

- Profilamiento del espesor láser a través de ancho y longitud

- Trazabilidad completa desde la identificación de la fusión hasta el envío final

Sostenibilidad y valor del ciclo de vida

- 60~80% contenido reciclado

- Completamente reciclable al final de su vida útil

- Permite diseños más delgados (por ejemplo, 1,2 mm frente a 1,5 mm) → ahorro de peso → menores emisiones de CO2

- La larga vida útil reduce la frecuencia de reemplazo y el consumo de recursos

Embalaje y entrega

- Hojas: entrelazadas con papel antirrastre, sujetas a palets de exportación

- Las bobinas: envueltas en VCI, impermeables, montadas en núcleos de hierro

- Logística global por mar, aire o tierra

- Tiempo de entrega: 715 días (en existencias); 3045 días (pedidos a medida)

Socio con confianza

- Consultoría técnica para la selección de materiales y la optimización de procesos

- Apoyo al prototipo con entrega rápida de muestras

- Servicios de valor añadido: corte, blanqueo, corte láser, acondicionamiento de bordes

- Programas de inventario justo a tiempo (JIT) para clientes de gran volumen