Todos os Produtos

-

Raian IonescuQualidade material muito boa. nós temos cooperar mais de 10 anos. Trocam tipos dos lotes do material de aço. Toda a qualidade material boa. Eles dever para toda a qualidade material. Nós estamos aplanando para continuar a cooperar no futuro com eles

Raian IonescuQualidade material muito boa. nós temos cooperar mais de 10 anos. Trocam tipos dos lotes do material de aço. Toda a qualidade material boa. Eles dever para toda a qualidade material. Nós estamos aplanando para continuar a cooperar no futuro com eles

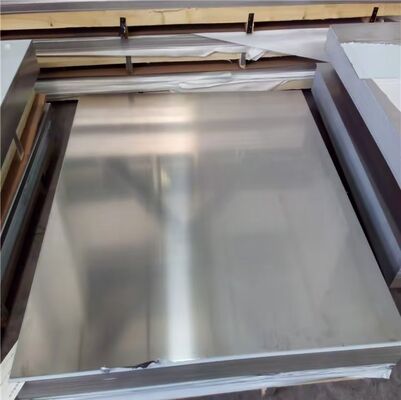

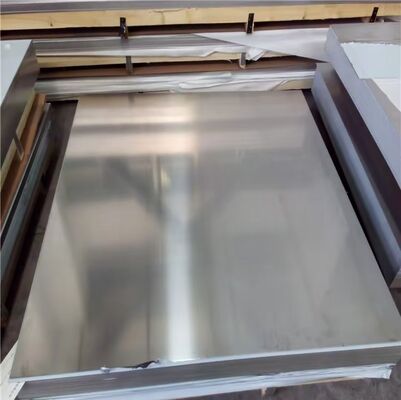

Chapa de aço inoxidável 439 laminada com precisão e otimizada para resistência ao calor e durabilidade

| Lugar de origem | China |

|---|---|

| Marca | TISCO |

| Certificação | ISO |

| Número do modelo | 439 |

| Quantidade de ordem mínima | 500 kgs |

| Preço | 1.5 - 2USD/Kg |

| Detalhes da embalagem | Embalagem padrão para exportação |

| Tempo de entrega | 5 - 12 dias com base na quantidade |

| Termos de pagamento | L/C, T/T, Western Union |

| Habilidade da fonte | 20ton por semana |

Detalhes do produto

| produtos | Chapa de aço inoxidável | Nota | 439 |

|---|---|---|---|

| Grossura | 0,5 - 10,0 | Tecnologia | Cold rolou |

| Largura | 1219mm | Superfície | 2B 2D NO.1 |

| Padrão | RUÍDO DO EN DE ASTM GB JIS | Quantidade mínima | 1 tonelada |

| Destacar | 439 Chapa de aço inoxidável resistente ao calor,Chapas de aço inoxidável laminadas de precisão,chapa de aço inoxidável durável 439 |

||

Descrição de produto

Chapa de aço inoxidável 439 laminada com precisão e otimizada para resistência ao calor e durabilidade

Especificações das chapas de aço inoxidável

| Nome | 439 Placas de aço inoxidável |

| A nossa nota |

Série 200: 201 202 Série 300: 301 304,304L,304H,309S,310S,314,316L,316Ti,316H,316LN,317L,321,329,347 Série 400: 409L410,410S,415,416,420,430,431436 litros.439,441,443,444,445,446 Super aço inoxidável: 904L,926254SMO, 654SMO, 15-5PH, 17-4PH, 17-7PH, etc. Liga de níquel: C276, C22, G35, Liga X, Monel 400, K500, Inconel 600,601,617,625,718Incoloy 800,800H,800HT,825etc. |

| Técnica | Enrolados a quente, enrolados a frio, forjados |

| Padrão | JIS, AISI, ASTM, DIN, TUV, BV, SUS, etc. |

| Espessura | 0.1 80 mm |

| Faixa de largura | 10 mm 2000 mm |

| Duração | Personalizado |

| Acaba. | 2B, 2D, NÃO.1BA, não.4, 8k, escovado, linha do cabelo, revestimento PVD, arejado |

| Serviço | Corte a laser, dobra |

| Amostra | Disponível |

Folha de aço inoxidável 439 laminada com precisão Optimizada para resistência ao calor e durabilidade

Visão geral do produto

A chapa de aço inoxidável de grau 439 laminada de precisão é uma chapa de aço inoxidável ferrítico de alto desempenho estabilizada com titânio, concebida para aplicações que exigem uma resistência ao calor excepcional,durabilidade a longo prazoIdeal para sistemas de escape de automóveis, trocadores de calor industriais, caixas de conversores catalíticos e blindagem térmica.Este material combina a metalurgia avançada com uma laminação a frio de alta tolerância para proporcionar propriedades mecânicas consistentes e qualidade da superfície..

Fabricadas de acordo com padrões rigorosos em espessuras de 0,8 mm a 10,0 mm, as nossas folhas 439 laminadas com precisão apresentam tolerância de espessura de ±0,02 mm, estrutura de grãos uniforme,e defeitos de superfície mínimos, garantindo um desempenho óptimo em altas temperaturas, ambientes de elevada corrosão onde a fiabilidade não é negociável.

Por que é importante a precisão do rolamento

Diferentemente dos produtos laminados a frio normais a quente ou a frio com controlo fraco, os aços inoxidáveis 439 laminados a precisão são submetidos a:

- Redução a frio de múltiplos passos com espaços de rolagem controlados por computador

- Requeijão contínua em atmosferas de hidrogénio-nitrogénio para suavidade e limpeza

- Limpeza e decapagem eletrolítica de superfícies sem óxido

- Medimento a laser em linha para monitorização da espessura em tempo real

O resultado? folhas com uma planitud superior, resposta mecânica consistente e formabilidade melhorada - críticos para estampagem automatizada, soldadura robótica e fabricação de alto rendimento.

Projetado para condições extremas

O grau 439 se destaca onde as temperaturas excedem 650 ° C (1200 ° F) e condensados corrosivos estão presentes.

✅ Excelente resistência à oxidação

Estável até 800 °C (1472 °F) devido a uma camada Cr2O3 densa e auto-curável que resiste a escamação e espalhamento.

Estável até 800 °C (1472 °F) devido a uma camada Cr2O3 densa e auto-curável que resiste a escamação e espalhamento.

✅ Estabilização de titânio

O Ti liga o carbono e o nitrogénio, evitando o esgotamento do cromo nos limites dos grãos, eliminando a corrosão intergranular após soldagem ou exposição prolongada a altas temperaturas.

O Ti liga o carbono e o nitrogénio, evitando o esgotamento do cromo nos limites dos grãos, eliminando a corrosão intergranular após soldagem ou exposição prolongada a altas temperaturas.

✅ Baixa expansão térmica

A estrutura ferrítica oferece uma expansão 30% menor do que as classes austeníticas, reduzindo a deformação e o cansaço das articulações em aplicações de aquecimento cíclico.

A estrutura ferrítica oferece uma expansão 30% menor do que as classes austeníticas, reduzindo a deformação e o cansaço das articulações em aplicações de aquecimento cíclico.

✅ Alta durabilidade

Resiste a saltos de estrada, condensados ácidos (H2SO4, HNO3) e gases de escape ricos em enxofre, prolongando a vida útil dos componentes em 2×3× em comparação com o aço leve ou 409 inoxidável.

Resiste a saltos de estrada, condensados ácidos (H2SO4, HNO3) e gases de escape ricos em enxofre, prolongando a vida útil dos componentes em 2×3× em comparação com o aço leve ou 409 inoxidável.

✅ Excelentes características de fabricação

Apesar de sua resistência à temperatura, mantém > 25% de alongamento para desenho profundo, dobra e hidroformação sem rachaduras.

Apesar de sua resistência à temperatura, mantém > 25% de alongamento para desenho profundo, dobra e hidroformação sem rachaduras.

Especificações técnicas

| Parâmetro | Detalhes |

|---|---|

| Grau | UNS S43035 / ASTM A240 Tipo 439 / EN 1.4510 / JIS SUS 439 |

| Formulário | Folhas laminadas a frio de precisão |

| Faixa de espessura | 0.8 mm 10.0 mm (tolerâncias personalizadas disponíveis) |

| Tolerância padrão | ± 0,02 mm (para 0,8 ∼ 3,0 mm); ± 0,05 mm (para > 3,0 mm) |

| Largura | 600~2000 mm (padrão); disponível corte sob medida |

| Durações | Corte em comprimento (por exemplo, 2438 mm / 8 ft) ou em espiral |

| Revestimento de superfície | 2B (padrão), BA, Hairline ou especificado pelo cliente |

| Normas | ASTM A240, EN 10088-2, JIS G4305, GB/T 4237 |

| Certificações | ISO 9001, IATF 16949, RoHS; EN 10204 3.1 MTR fornecidos |

Composição química (típica, em peso%)

| Elementos | C | Sim | - Não | P | S | Cr | Não. | N | Ti |

|---|---|---|---|---|---|---|---|---|---|

| Max/intervalo | ≤ 0.03 | ≤ 1.0 | ≤ 1.0 | ≤ 0.04 | ≤ 0.03 | 17.0 ¢ 19.0 | ≤ 0.5 | ≤ 0.04 | ≥ 0,2 + 4 × ((C+N); ≤ 1.10 |

Nota: O controlo rigoroso do C+N (< 0,05%) e do Ti garante a máxima eficiência de estabilização.

Propriedades mecânicas e físicas (condição de aquecimento)

| Imóveis | Valor típico |

|---|---|

| Resistência à tração | 450 600 MPa |

| Força do rendimento (0,2% de compensação) | ≥ 280 MPa |

| Extensão | ≥ 25% (em 50 mm) |

| Dureza (HRB) | ≤ 88 |

| Densidade | 70,70 g/cm3 |

| Conductividade térmica (100°C) | 26 W/m·K |

| Coeficiente de expansão térmica (20 ̊100°C) | 10.4 × 10−6 /°C |

| Temperatura máxima de funcionamento contínuo | 800°C (1472°F) |

Aplicações

- Automóveis: colectores de escape, capas de conversores catalíticos, silenciadores, tubos de escape

- Indústria: tubos de queimadores, condutas de gases de combustão, unidades de recuperação de calor

- Aparelhos: revestimentos de fornos, reservatórios de máquinas de lavar louça, tambores de secadores

- Energia: componentes de caldeiras de biomassa, receptores solares térmicos

O 439 laminado de precisão é especialmente valorizado em sistemas críticos em termos de emissões, onde a falha do material coloca em risco a não conformidade regulamentar ou reivindicações de garantia.

Vantagens em relação às notas padrão

| Características | Fabricação a partir de metais de ferro ou aço | Padrão 409 | Outros, de peso superior a 200 g/m2 |

|---|---|---|---|

| Tolerância de espessura | ± 0,02 mm | ± 0,10 mm ou inferior | ± 0,20 mm |

| Qualidade da superfície | Suave, sem defeitos | Escala, poços comuns | Óleos essenciais |

| Consistência de formabilidade | Alto (grão uniforme) | Variavel | Pobre. |

| Rendimento pós-fabricação | > 95% | 80 ∼ 85% | < 80% |

| Desempenho em alta velocidade | Excelente. | Moderado | É justo. |

Esta consistência traduz-se em taxas de sucata mais baixas, tempos de ciclo mais rápidos e retrabalho reduzido.

Processo de garantia da qualidade

Cada bobina/folha é submetida a:

- Verificação espectrométrica da química

- Ensaios de tração e dureza por lote

- Inspecção automatizada de superfícies (câmaras CCD detectam micro-defeitos)

- Profil de espessura do laser em largura e comprimento

- Rastreamento completo desde a identificação da fusão até à remessa final

Todos os produtos cumprem a norma IATF 16949, a norma global de qualidade automotiva.

Sustentabilidade e valor do ciclo de vida

- 60~80% de conteúdo reciclado

- Totalmente reciclável no final da vida útil

- Permite projetos mais finos (por exemplo, 1,2 mm versus 1,5 mm) → redução de peso → emissões de CO2 mais baixas

- Uma longa vida útil reduz a frequência de substituição e o consumo de recursos

Um verdadeiro material "verde" para uma fabricação sustentável.

Embalagem e entrega

- Folhas: entrelaçadas com papel anti-arranhões, amarradas a paletes de exportação

- Empilhadeiras: revestidas com VCI, impermeáveis, montadas em núcleos de ferro

- Logística global por via marítima, aérea ou terrestre

- Prazo de entrega: 715 dias (estoque); 3045 dias (encomendas personalizadas)

Parceiro Com Confiança

Oferecemos mais do que material:

- Consultoria técnica para selecção de materiais e otimização de processos

- Apoio ao protótipo com entrega rápida de amostras

- Serviços de valor acrescentado: corte, blanqueamento, corte a laser, condicionamento de bordas

- Programas de inventário just-in-time (JIT) para clientes de grande volume

Conclusão

A chapa de aço inoxidável de grau 439 laminada de precisão estabelece uma nova referência para resistência ao calor, precisão dimensional e durabilidade a longo prazo em ambientes extremos.Combinando a tecnologia avançada de laminação com a química comprovada do aço inoxidável ferrítico estabilizado com titânio, oferece uma fiabilidade incomparável para componentes de missão crítica.

Chapa de aço inoxidável 439 laminada a altas temperaturas, chapa de aço inoxidável resistente ao calor do grau 439, chapa de aço inoxidável ferrítico estabilizada com titânio, chapa de aço inoxidável 439 laminada a frio de precisão ASTM 439,aço inoxidável resistente à oxidação, folha de aço inoxidável de escape automotivo, placa de precisão EN 1.4510, resistente 439 inoxidável para colectores, fornecedor 439 certificado pela IATF 16949, tolerância de inoxidável ± 0,02 mm.

Produtos recomendados