모든 제품

-

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

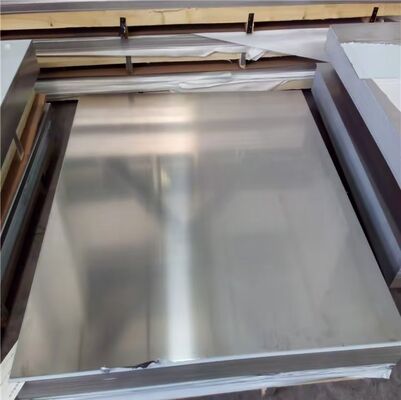

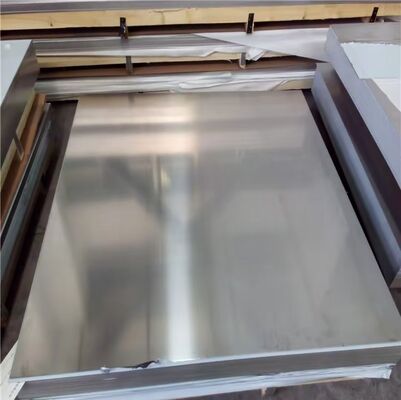

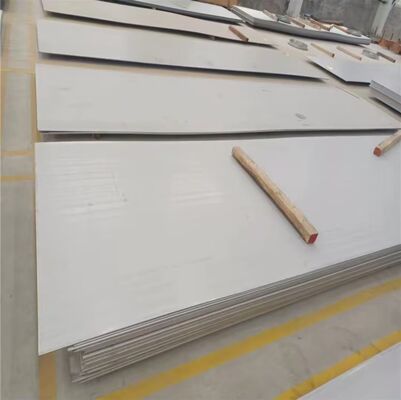

정밀 으로 롤링 된 439 장 스테인레스 스틸 은 열 저항성 과 내구성 을 위해 최적화 되어 있다

제품 상세 정보

| 제품 | 스테인레스 스틸 시트 | 등급 | 439 |

|---|---|---|---|

| 두께 | 0.5 - 10.0 | 기술 | 콜드 롤 |

| 너비 | 1219 밀리미터 | 표면 | 2B 2D NO.1 |

| 기준 | ASTM GB JIS EN DIN | MOQ | 1톤 |

| 강조하다 | 439 열 저항성 스테인레스 스틸 엽,정밀 롤링 스테인레스 스틸 엽,내구성 있는 스테인레스 스틸 판 439 |

||

제품 설명

정밀 으로 롤링 된 439 장 스테인레스 스틸 은 열 저항성 과 내구성 을 위해 최적화 되어 있다

스테인레스 스틸 판 사양

| 이름 | 439 스테인레스 스틸 판 |

| 우리 의 등급 |

200 시리즈: 201 202 300 시리즈: 301 304,304L,304H,309S,310S,314316L,316Ti,316H,316LN,317L321,329,347 400 시리즈: 409L,410,410S415,416,420,430,431436리터439,441,443,444,445,446 슈퍼 스테인리스 스틸: 904L,926254SMO, 654SMO, 15-5PH, 17-4PH, 17-7PH 등 니켈 합금: C276, C22, G35, 합금 X, 모넬 400, K500, 인코넬 600,601,617,625,718인콜로이 800,800H,800HT825등등 |

| 기술 | 핫 롤링, 콜드 롤링, 위장 |

| 표준 | JIS, AISI, ASTM, DIN, TUV, BV, SUS 등 |

| 두께 | 0.1 80mm |

| 너비 범위 | 10mm 2000mm |

| 길이 | 맞춤형 |

| 끝내 | 2B, 2D, NO1B.A, 아니4, 8K, 빗, 헤어 라인, PVD 코팅, 샌드 블래스트 |

| 서비스 | 레이저 절단, 굽기 |

| 표본 | 사용 가능 |

정밀 롤 439 스테인레스 스틸 엽 ∼ 열 저항성 과 내구성 에 최적화 되어 있다

제품 개요

정밀 롤링 439급 스테인리스 스틸은 고성능, 티타늄 안정화 페리트 스테인리스 스틸로,장기적인 내구성자동차 배기가스 시스템, 산업용 열 교환기, 촉매 변환기 가구 및 열 차단기이 재료는 첨단 금속공학과 엄격한 내성 냉 lamination을 결합하여 일관된 기계적 특성과 표면 품질을 제공합니다..

0.8mm에서 10.0mm까지의 두께에서 엄격한 표준에 따라 제조 된 우리의 정밀 롤 439 장은 ± 0.02mm 두께 허용, 균일한 곡물 구조,고온에서 최적의 성능을 보장하는, 신뢰성이 협상 불가능한 고성질 환경

왜 정확 한 롤링 이 중요 합니까?

표준 열불 또는 느슨하게 제어 된 냉불 제품과 달리 정밀 롤 439 스테인레스 스틸은 다음과 같은 과정을 거칩니다.

- 컴퓨터로 제어되는 롤 틈을 가진 다발 냉소

- 부드러움과 청결성을 위해 수소-질소 대기에서 연속 굽기

- 산화물 없는 표면의 전해질 청소 및 비클링

- 실시간 두께 모니터링을 위한 라인 레이저 측정

그 결과, 우수한 평면성, 일관성 있는 기계적 반응, 그리고 자동 스탬핑, 로봇 용접, 그리고 고출력 제조에 필수적인 향상된 형태성.

극단적 인 조건 을 위해 설계 된 것

등급 439은 온도가 650 ° C (1200 ° F) 를 초과하고 부식성 응고물이있는 곳에서 우수합니다. 주요 성능 특성은 다음을 포함합니다.

✅ 탁월 한 산화 저항성

800°C (1472°F) 까지 안정성 있는 밀도가 높고 자기 치유 Cr2O3 층으로 인해 껍질이 쪼개지거나 쪼개지는 것을 견딜 수 있다.

800°C (1472°F) 까지 안정성 있는 밀도가 높고 자기 치유 Cr2O3 층으로 인해 껍질이 쪼개지거나 쪼개지는 것을 견딜 수 있다.

✅ 티타늄 안정화

Ti는 탄소와 질소를 결합하여 곡물 경계에서 크롬의 고갈을 방지합니다.

Ti는 탄소와 질소를 결합하여 곡물 경계에서 크롬의 고갈을 방지합니다.

✅ 낮은 열 확장

페리트 구조는 오스텐이트 등급보다 30% 더 낮은 팽창을 제공하며, 순환 난방 응용 프로그램에서 변형 및 관절 피로를 줄입니다.

페리트 구조는 오스텐이트 등급보다 30% 더 낮은 팽창을 제공하며, 순환 난방 응용 프로그램에서 변형 및 관절 피로를 줄입니다.

✅ 높은 내구성

도로 소금, 산성 응고물 (H2SO4, HNO3) 및 황이 풍부한 배기가스에서 구덩이를 견딜 수 있습니다. 부드러운 철강 또는 409 스테인리스에 비해 부품 수명을 2 × 3 × 늘립니다.

도로 소금, 산성 응고물 (H2SO4, HNO3) 및 황이 풍부한 배기가스에서 구덩이를 견딜 수 있습니다. 부드러운 철강 또는 409 스테인리스에 비해 부품 수명을 2 × 3 × 늘립니다.

✅ 우수한 제조 특성

온도에서 강함에도 불구하고, 그것은 크래킹없이 깊은 드래잉, 구부러기 및 수소 형성에 대한> 25% 연장도를 유지합니다.

온도에서 강함에도 불구하고, 그것은 크래킹없이 깊은 드래잉, 구부러기 및 수소 형성에 대한> 25% 연장도를 유지합니다.

기술 사양

| 매개 변수 | 세부 사항 |

|---|---|

| 등급 | UNS S43035 / ASTM A240 타입 439 / EN 1.4510 / JIS SUS 439 |

| 양식 | 정밀 냉장판 |

| 두께 범위 | 0.8 mm ∙ 10.0 mm (자격 허용도 가능) |

| 표준 허용량 | ±0.02mm (0.8~3.0mm의 경우) ±0.05mm (>3.0mm의 경우) |

| 너비 | 600~2000mm (표준) 의 맞춤 절단 가능 |

| 길이 | 길이에 따라 절단 (예를 들어, 2438 mm / 8 ft) 또는 코일 |

| 표면 마감 | 2B (표준), BA, Hairline 또는 고객 지정 |

| 표준 | ASTM A240, EN 10088-2, JIS G4305, GB/T 4237 |

| 인증서 | ISO 9001, IATF 16949, RoHS, EN 10204 3.1 MTR |

화학 성분 (유형, wt%)

| 원소 | C | 네 | 원 | P | S | Cr | 니 | N | 티 |

|---|---|---|---|---|---|---|---|---|---|

| 최대/범위 | ≤0.03 | ≤1.0 | ≤1.0 | ≤0.04 | ≤0.03 | 170.0190 | ≤0.5 | ≤0.04 | ≥0.2 + 4×(C+N); ≤1.10 |

참고: C+N (<0.05%) 및 Ti의 엄격한 통제는 최대 안정화 효율을 보장합니다.

기계적 및 물리적 특성 (연금 상태)

| 재산 | 전형적 가치 |

|---|---|

| 팽창 강도 | 450~600 MPa |

| 수익성 (Yield Strength) (0.2% 오프셋) | ≥280 MPa |

| 길쭉함 | ≥25% (50mm) |

| 강도 (HRB) | ≤ 88 |

| 밀도 | 7.70g/cm3 |

| 열전도성 (100°C) | 26W/m·K |

| 열 확장 계수 (20~100°C) | 10.4 × 10−6 /°C |

| 최대 연속 서비스 온도 | 800°C (1472°F) |

신청서

- 자동차: 배기가스 매니폴트, 촉매 변환기 껍데기, 소음 차단기, 배기가스 파이프

- 산업용: 연소관, 연소 가스 통, 열 회수 장치

- 가전: 오븐 라인, 식기 세척기 탱크, 드라이어 드럼

- 에너지: 바이오매스 보일러 부품, 태양 열 수신기

정밀 롤링 439은 특히 물질 고장이 규제 불충분 또는 보증 청구의 위험을 초래하는 중요한 배출 시스템에서 가치가 있습니다.

표준 학위 보다 더 좋은 점수

| 특징 | 정밀 롤링 439 | 표준 409 | 핫 롤 430 |

|---|---|---|---|

| 두께 허용 | ±0.02mm | ±0.10mm 이상 | ±0.20mm |

| 표면 품질 | 부드럽고 결함 없는 | 비늘, 덩어리 일반 | 거친, 산화 |

| 형태성 일관성 | 높은 (일률적인 곡물) | 변수 | 가난한 사람 |

| 제조 후 생산량 | >95% | 80~85% | < 80% |

| 하이 템프 공연 | 훌륭해요 | 중간 | 공평하다 |

이러한 일관성은 더 낮은 폐기율, 더 빠른 사이클 시간, 그리고 더 적은 재작업으로 이어집니다.

품질 보장 과정

각 롤/플릿은 다음과 같은 테스트를 받습니다.

- 분광 화학 검증

- 매트당 튼성 및 경직성 검사

- 자동 표면 검사 (CCD 카메라로 미세 결함을 감지)

- 레이저 두께 프로파일 너비와 길이를 통해

- 용해 ID에서 최종 운송까지의 완전한 추적성

모든 제품은 IATF 16949을 준수합니다. 세계 자동차 품질 표준입니다.

지속가능성 및 라이프사이클 가치

- 60~80% 재활용 함유

- 사용후 완전히 재활용 가능

- 더 얇은 디자인 (예를 들어, 1.2 mm 대 1.5 mm) → 무게 절감 → 낮은 CO2 배출

- 긴 사용 기간은 교체 빈도와 자원 소비를 줄입니다.

지속가능한 제조를 위한 진정한 친환경 물질입니다.

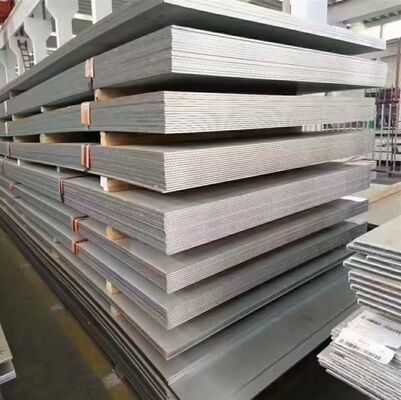

포장 및 배달

- 잎: 스크래치 방지용 종이에 겹쳐져 있으며, 수출 팔렛에 묶여 있습니다.

- 코일: VCI로 싸여, 방수, 철핵에 장착

- 해상, 공중 또는 육상으로 전 세계 물류

- 납품 시간: 7~15일 (주류); 30~45일 (세종 주문)

자신감 있는 동반자

우리는 자료를 제공하는 것 이상의 것을 제공합니다.

- 재료 선택 및 프로세스 최적화 기술 컨설팅

- 신속한 샘플 제공으로 프로토타입 지원

- 부가가치 서비스: 썰기, 빗, 레이저 절단, 가장자리 컨디셔닝

- 저-인타임 (JIT) 인벤토리 프로그램

결론

정밀 롤링 439등급 스테인리스 스틸 시트는 열 저항성, 차원 정확성, 극한 환경에서의 장기 내구성에 대한 새로운 기준을 설정합니다.첨단 롤링 기술과 티타늄 안정화 된 페리틱 스테인리스 스틸의 검증 된 화학 물질을 결합하여미션 크리티컬 컴포넌트에서 비교할 수 없는 신뢰성을 제공합니다.

정밀 롤드 439 스테인레스 스틸 장판, 439 등급 열 저항성 스테인레스, 티타늄 안정화 페리트 스테인레스 스틸, 고온 439 장판, ASTM 439 정밀 냉불,산화 저항성 스테인레스 스틸, 자동차 배기가스 스테인레스 시트, EN 1.4510 정밀판, 내구성 439 스테인레스 소매체, IATF 16949 인증 439 공급자, ± 0.02mm 스테인레스 허용.

추천된 제품