Hoja de acero inoxidable ferrítico 409L: Solución rentable para aplicaciones de alta temperatura

Especificaciones de la placa de acero inoxidable

| Nombre |

Placa de acero inoxidable 409L |

| Nuestro grado |

Serie 200: 201 202

Serie 300: 301 304,304L,304H,309S,310S,314,316L,316Ti,316H,316LN,317L,321,329,347

Serie 400: 409L,410,410S,415,416,420,430,431,436L.439,441,443,444,445,446

Acero inoxidable súper: 904L,926,254SMO,654SMO,15-5PH,17-4PH,17-7PH.etc

Aleación de níquel: C276, C22,G35,Aleación X,Monel 400,K500,Inconel 600,601,617,625,718,Incoloy 800,800H,800HT,825.etc

|

| Técnica |

Laminado en caliente, laminado en frío, forjado |

| Estándar |

JIS, AISI, ASTM, DIN, TUV, BV, SUS, etc. |

| Espesor |

0.1 – 80.0 mm |

| Rango de ancho |

10 mm – 2000 mm |

| Longitud |

Personalizado |

| Acabado |

2B, BA, No.4, 8k, Cepillado, Línea fina, Recubrimiento PVD, Chorro de arena |

| Servicio |

Corte por láser, doblado |

| Muestra |

Disponible |

Hoja de acero inoxidable ferrítico 409L – Una solución rentable para aplicaciones de alta temperatura

Introducción

En industrias donde la estabilidad térmica, la resistencia a la corrosión y la eficiencia presupuestaria se cruzan, como la fabricación de automóviles, los sistemas de escape y la gestión del calor industrial, la hoja de acero inoxidable ferrítico 409L se ha convertido en el material de elección. Diseñado para un rendimiento en condiciones extremas sin la etiqueta de precio premium de los grados austeníticos como el 304 o el 316, el 409L ofrece un equilibrio inteligente de funcionalidad, durabilidad y asequibilidad.

Esta descripción general técnica del producto explora por qué el acero inoxidable 409L es la solución ideal para aplicaciones de alta temperatura, detallando su composición, propiedades mecánicas, cumplimiento de estándares y ventajas en el mundo real, todo respaldado por datos y las mejores prácticas de la industria.

¿Qué es el acero inoxidable 409L?

El 409L (UNS S40903) es un acero inoxidable ferrítico de bajo carbono estabilizado con titanio. Pertenece a la familia de la serie 400 y contiene aproximadamente un 11% de cromo, con un contenido de carbono estrictamente limitado a ≤ 0.03%. La adición de titanio (Ti), típicamente ≥6 × el contenido de carbono, evita la precipitación de carburo de cromo durante la soldadura o la exposición a temperaturas elevadas, eliminando así la sensibilización y la corrosión intergranular.

A diferencia de los aceros inoxidables austeníticos, el 409L es magnético, no se endurece mediante tratamiento térmico y ofrece una menor expansión térmica, lo que lo hace excepcionalmente estable en entornos de calentamiento cíclico.

Por qué el 409L sobresale en aplicaciones de alta temperatura

Los sistemas de escape modernos, los convertidores catalíticos y los conductos industriales operan rutinariamente entre 400 °C y 650 °C (752 °F–1202 °F). En estas condiciones, el 409L demuestra:

- Resistencia a la oxidación hasta 650 °C debido a su capa protectora de óxido de cromo

- Resistencia a la fatiga térmica de los ciclos repetidos de expansión/contracción

- Integridad estructural sin deformaciones ni incrustaciones bajo calor prolongado

- Compatibilidad con tecnologías de control de emisiones (por ejemplo, Euro 6, EPA Tier 3)

Su microestructura ferrítica proporciona una conductividad térmica más baja que los grados austeníticos, lo que reduce la transferencia de calor a los componentes circundantes, una ventaja crítica en los compartimentos de motor compactos.

Ventajas clave del acero inoxidable ferrítico 409L

| Característica |

Beneficio |

| Bajo carbono + estabilización con Ti |

Previene la degradación de la soldadura; no se necesita recocido posterior a la soldadura |

| Aleación rentable |

Sin níquel ni molibdeno = 30–50% menos de costo que el acero inoxidable 304 |

| Buena conformabilidad y soldabilidad |

Fácilmente estampado, doblado y soldado con equipos estándar |

| Resistencia moderada a la corrosión |

Supera al acero dulce y al acero aluminizado en exposición a condensados y sal de carretera |

| Reciclable y sostenible |

>95% de reciclabilidad apoya los objetivos de la economía circular |

| Naturaleza magnética |

Permite la manipulación automatizada en líneas de montaje robóticas |

Especificaciones técnicas

Composición química (Cumple con ASTM A240 / JIS G 4305)

| Elemento |

Rango típico (%) |

| Carbono (C) |

≤ 0.03 |

| Cromo (Cr) |

10.5 – 11.7 |

| Titanio (Ti) |

≥ 6×C, ≤ 0.75 |

| Manganeso (Mn) |

≤ 1.00 |

| Silicio (Si) |

≤ 1.00 |

| Fósforo (P) |

≤ 0.040 |

| Azufre (S) |

≤ 0.030 |

| Níquel (Ni) |

≤ 0.50 |

| Hierro (Fe) |

Balance |

Propiedades mecánicas (Condición recocida)

| Propiedad |

Valor |

| Resistencia a la tracción |

415 – 520 MPa |

| Límite elástico (0.2% de desplazamiento) |

275 – 380 MPa |

| Alargamiento |

≥ 20% |

| Dureza |

≤ 85 HRB |

| Densidad |

7.75 g/cm³ |

| Temperatura máxima de servicio continuo |

650 °C (1202 °F) |

| Conductividad térmica (100 °C) |

~25.8 W/m·K |

| Coeficiente de expansión térmica (20–100 °C) |

10.6 × 10⁻⁶ /K |

Nota: Las variantes laminadas en frío ofrecen mayor resistencia; las versiones laminadas en caliente proporcionan mejor ductilidad a alta temperatura.

Formas y acabados comunes del producto

El 409L está disponible en múltiples formatos para adaptarse a diversas necesidades de fabricación:

| Forma |

Rango de espesor |

Acabado típico |

Uso principal |

| Hoja/placa laminada en caliente |

2.0 – 12.0 mm |

NO.1 (mate, descalado) |

Colectores de escape, carcasas de silenciadores |

| Hoja laminada en frío |

0.3 – 4.0 mm |

2B (liso, semibrillante) |

Carcasas de convertidores catalíticos, tubos de escape |

| Bobina |

0.4 – 6.0 mm |

2D o 2B |

Operaciones de estampado de alto volumen |

Todos los productos cumplen con ASTM A240, JIS G 4304 (laminado en caliente), JIS G 4305 (laminado en frío), EN 10088-2 e ISO 15510.

Aplicaciones del mundo real

El acero inoxidable 409L es la columna vertebral del diseño moderno de vehículos que cumplen con las emisiones:

- Automóviles de pasajeros y camiones ligeros:

- Colectores de escape

- Tuberías flexibles y tuberías intermedias

- Silenciadores y resonadores

- Carcasas exteriores de convertidores catalíticos

- Vehículos comerciales y todoterreno:

- Carcasas de filtros de partículas diésel (DPF)

- Componentes del sistema de reducción catalítica selectiva (SCR)

- Usos industriales:

- Intercambiadores de calor (no agua de mar)

- Accesorios de horno

- Escapes de maquinaria agrícola

Cada vehículo suele utilizar entre 40 y 65 kg de 409L, lo que lo convierte en uno de los grados de acero inoxidable más consumidos a nivel mundial.

Directrices de fabricación

Soldadura

- Fácilmente soldable mediante soldadura TIG, MIG o por puntos por resistencia

- No se requiere precalentamiento ni tratamiento térmico posterior a la soldadura

- Utilice alambre de relleno ER409L o ER430 para obtener resultados óptimos

Formación

- Excelente conformabilidad en frío para radios de curvatura ≥ 2 × espesor

- Evite muescas afiladas o estiramientos excesivos en los bordes

Mecanizado

- Mecanizabilidad moderada; utilice herramientas afiladas y lubricación adecuada

- No es ideal para roscado de alta precisión

Exposición al calor

- Estable hasta 650 °C de servicio continuo

- Picos a corto plazo de hasta 750 °C aceptables, pero pueden causar incrustaciones en la superficie

Comparación de costos frente a alternativas

| Material |

Costo relativo (Índice) |

Temperatura máxima |

Resistencia a la corrosión |

Notas |

| Acero inoxidable 409L |

1.0 (línea de base) |

650 °C |

Moderada |

La mejor relación calidad-precio para sistemas de escape |

| Acero aluminizado |

0.7 |

550 °C |

Baja-Moderada |

Más barato pero con una vida útil más corta |

| Acero inoxidable 304 |

2.0–2.5 |

870 °C |

Alta |

Sobrediseñado para muchos usos de escape |

| Acero inoxidable 439 |

1.4 |

800 °C |

Buena |

Utilizado en sistemas premium/de alto rendimiento |

El 409L ofrece el menor costo total de propiedad en aplicaciones de temperatura media.

Garantía de calidad y certificación

Cada lote se somete a:

- Análisis químico espectrométrico

- Pruebas de tracción y dureza

- Inspección por ultrasonidos o corrientes de Foucault (bajo petición)

- Verificación de la calidad de la superficie según las normas de iluminación ISO

Se proporcionan certificados de prueba de fábrica (MTC) según EN 10204 3.1, lo que garantiza la trazabilidad y el cumplimiento total.

Impacto ambiental

- 98% reciclable al final de su vida útil

- Permite diseños de vehículos más ligeros, reduciendo las emisiones de CO₂

- Elimina la necesidad de reemplazo frecuente → menor consumo de recursos

- Apoya los objetivos de sostenibilidad de los OEM (por ejemplo, la iniciativa “Carbono neutral para 2050” de Ford)

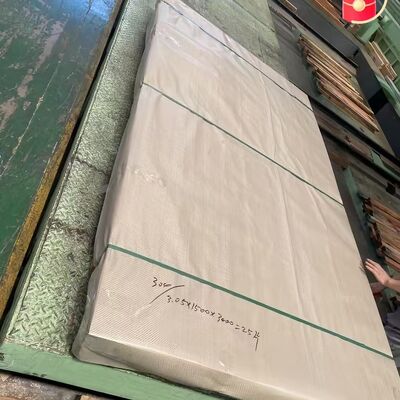

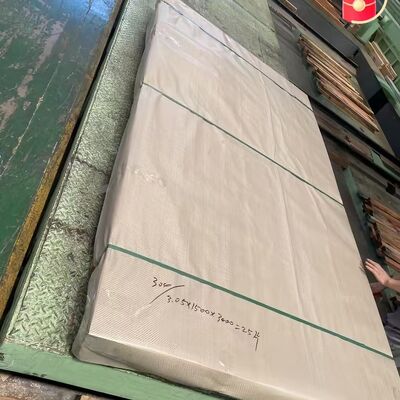

Embalaje y entrega

- Hojas/bobinas protegidas con papel anticorrosión VCI

- Bordes reforzados con protectores de esquina de plástico

- Paletizado y flejado para transporte terrestre u oceánico seguro

- Corte personalizado (corte longitudinal, corte en blanco, nivelación) disponible

Tamaños estándar:

- Ancho: 1000–1500 mm

- Longitud: 2000–6000 mm (o bobina)

- Espesor: 0.3–12.0 mm (según el proceso)

Conclusión

Para los ingenieros y los equipos de adquisiciones que buscan un material confiable, económico y preparado para el futuro para entornos de alta temperatura, la hoja de acero inoxidable ferrítico 409L es inigualable. Cierra la brecha entre el acero al carbono de bajo costo y las aleaciones austeníticas de alto rendimiento, pero costosas, ofreciendo durabilidad probada, facilidad de fabricación y cumplimiento normativo a un precio accesible.

Con la confianza de los fabricantes de automóviles y líderes industriales mundiales durante décadas, el 409L no es solo un material, sino una ventaja estratégica.

Contáctenos hoy para obtener muestras, soporte técnico o precios por volumen, y construya de manera más inteligente, más caliente y de manera más sostenible con 409L.

Hoja de acero inoxidable ferrítico 409L, acero inoxidable rentable para altas temperaturas, material de escape 409L, acero inoxidable estabilizado con titanio, acero inoxidable S40903, hoja 409L para automoción, acero inoxidable para altas temperaturas, costo 409L vs 304, acero inoxidable ferrítico 409L, UNS S40903, JIS G 4305 409L, ASTM A240 409L, acero inoxidable resistente a la oxidación, hoja de acero inoxidable con bajo contenido de carbono.

Raian IonescuCalidad material muy buena. tenemos cooperar más de 10 años. Negocian clases de las porciones de material de acero. Toda la calidad material buena. Ellos deber para toda la calidad material. Estamos acepillando para continuar cooperando con ellos en el futuro

Raian IonescuCalidad material muy buena. tenemos cooperar más de 10 años. Negocian clases de las porciones de material de acero. Toda la calidad material buena. Ellos deber para toda la calidad material. Estamos acepillando para continuar cooperando con ellos en el futuro