All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

409L Ferritic Stainless Steel Sheet Cost-Effective Solution for High-Temperature Applications

Product Details

| Products | Stainless Steel Plate | Grade | 409L |

|---|---|---|---|

| Thickness | 0.5-50.0mm | Tech | Cold Rolled,hot Rolled , Forged |

| Width | 1000mm 1219mm 1500mm Or Customs As Request | Surface | 2D NO.1 |

| Standard | ASTM GB JIS EN DIN | MOQ | 1 Ton |

| Highlight | 409L ferritic stainless steel sheet,cost-effective stainless steel sheet,high-temperature stainless steel sheet |

||

Product Description

409L Ferritic Stainless Steel Sheet Cost-Effective Solution for High-Temperature Applications

Stainless Steel Plate Specifications

| Name | 409L stainless steel Plate |

| Our Grade |

200 Series: 201 202 300 Series: 301 304,304L,304H,309S,310S,314,316L,316Ti,316H,316LN,317L,321,329,347 400 Series: 409L,410,410S,415,416,420,430,431,436L.439,441,443,444,445,446 Super Stainless Steel: 904L,926,254SMO,654SMO,15-5PH,17-4PH,17-7PH.etc Nickel Alloy: C276, C22,G35,Alloy X,Monel 400,K500,Inconel 600,601,617,625,718,Incoloy 800,800H,800HT,825.etc |

| Technique | Hot Rolled, Cold Rolled,Forged |

| Standard | JIS, AISI, ASTM, DIN, TUV, BV, SUS, etc |

| Thickness | 0.1 – 80.0mm |

| Width range | 10mm – 2000mm |

| Length | Customized |

| Finish | 2B, BA, No.4, 8k, Brushed,Hairline,PVD Coating,Sandblasted |

| Service | Laser Cutting, Bending |

| Sample | Available |

409L Ferritic Stainless Steel Sheet – A Cost-Effective Solution for High-Temperature Applications

Introduction

In industries where thermal stability, corrosion resistance, and budget efficiency intersect—such as automotive manufacturing, exhaust systems, and industrial heat management—409L ferritic stainless steel sheet has emerged as the material of choice. Engineered for performance under extreme conditions without the premium price tag of austenitic grades like 304 or 316, 409L delivers a smart balance of functionality, durability, and affordability.

This technical product overview explores why 409L stainless steel is the go-to solution for high-temperature applications, detailing its composition, mechanical properties, standards compliance, and real-world advantages—all backed by data and industry best practices.

What Is 409L Stainless Steel?

409L (UNS S40903) is a low-carbon, titanium-stabilized ferritic stainless steel. It belongs to the 400-series family and contains approximately 11% chromium, with carbon content strictly limited to ≤ 0.03%. The addition of titanium (Ti)—typically ≥6× the carbon content—prevents chromium carbide precipitation during welding or exposure to elevated temperatures, thereby eliminating sensitization and intergranular corrosion.

Unlike austenitic stainless steels, 409L is magnetic, non-hardenable by heat treatment, and offers lower thermal expansion, making it exceptionally stable in cyclic heating environments.

Why 409L Excels in High-Temperature Applications

Modern exhaust systems, catalytic converters, and industrial ducting routinely operate between 400°C and 650°C (752°F–1202°F). In these conditions, 409L demonstrates:

- Oxidation resistance up to 650°C due to its protective chromium oxide layer

- Thermal fatigue resistance from repeated expansion/contraction cycles

- Structural integrity without warping or scaling under prolonged heat

- Compatibility with emission control technologies (e.g., Euro 6, EPA Tier 3)

Its ferritic microstructure provides lower thermal conductivity than austenitic grades, reducing heat transfer to surrounding components—a critical advantage in compact engine bays.

Key Advantages of 409L Ferritic Stainless Steel

| Feature | Benefit |

|---|---|

| Low Carbon + Ti Stabilization | Prevents weld decay; no post-weld annealing needed |

| Cost-Effective Alloying | No nickel or molybdenum = 30–50% lower cost than 304 stainless |

| Good Formability & Weldability | Easily stamped, bent, and welded using standard equipment |

| Moderate Corrosion Resistance | Outperforms mild steel and aluminized steel in condensate and road-salt exposure |

| Recyclable & Sustainable | >95% recyclability supports circular economy goals |

| Magnetic Nature | Enables automated handling in robotic assembly lines |

Technical Specifications

Chemical Composition (ASTM A240 / JIS G 4305 Compliant)

| Element | Typical Range (%) |

|---|---|

| Carbon (C) | ≤ 0.03 |

| Chromium (Cr) | 10.5 – 11.7 |

| Titanium (Ti) | ≥ 6×C, ≤ 0.75 |

| Manganese (Mn) | ≤ 1.00 |

| Silicon (Si) | ≤ 1.00 |

| Phosphorus (P) | ≤ 0.040 |

| Sulfur (S) | ≤ 0.030 |

| Nickel (Ni) | ≤ 0.50 |

| Iron (Fe) | Balance |

Mechanical Properties (Annealed Condition)

| Property | Value |

|---|---|

| Tensile Strength | 415 – 520 MPa |

| Yield Strength (0.2% offset) | 275 – 380 MPa |

| Elongation | ≥ 20% |

| Hardness | ≤ 85 HRB |

| Density | 7.75 g/cm³ |

| Max Continuous Service Temp | 650°C (1202°F) |

| Thermal Conductivity (100°C) | ~25.8 W/m·K |

| Coefficient of Thermal Expansion (20–100°C) | 10.6 × 10⁻⁶ /K |

Note: Cold-rolled variants offer higher strength; hot-rolled versions provide better high-temp ductility.

Common Product Forms & Finishes

409L is available in multiple formats to suit diverse manufacturing needs:

| Form | Thickness Range | Typical Finish | Primary Use |

|---|---|---|---|

| Hot-Rolled Sheet/Plate | 2.0 – 12.0 mm | NO.1 (matte, descaled) | Exhaust manifolds, muffler shells |

| Cold-Rolled Sheet | 0.3 – 4.0 mm | 2B (smooth, semi-bright) | Catalytic converter housings, tailpipes |

| Coil | 0.4 – 6.0 mm | 2D or 2B | High-volume stamping operations |

All products comply with ASTM A240, JIS G 4304 (hot-rolled), JIS G 4305 (cold-rolled), EN 10088-2, and ISO 15510.

Real-World Applications

409L stainless steel is the backbone of modern emission-compliant vehicle design:

- Passenger Cars & Light Trucks:

- Exhaust manifolds

- Flex pipes and intermediate pipes

- Mufflers and resonators

- Catalytic converter outer shells

- Commercial & Off-Highway Vehicles:

- Diesel particulate filter (DPF) housings

- Selective catalytic reduction (SCR) system components

- Industrial Uses:

- Heat exchangers (non-seawater)

- Furnace fixtures

- Agricultural machinery exhausts

Each vehicle typically uses 40–65 kg of 409L, making it one of the most widely consumed stainless grades globally.

Fabrication Guidelines

Welding

- Easily welded via TIG, MIG, or resistance spot welding

- No preheating or post-weld heat treatment required

- Use ER409L or ER430 filler wire for optimal results

Forming

- Excellent cold formability for bending radii ≥ 2× thickness

- Avoid sharp notches or excessive stretching at edges

Machining

- Moderate machinability; use sharp tools and adequate lubrication

- Not ideal for high-precision threading

Heat Exposure

- Stable up to 650°C continuous service

- Short-term peaks to 750°C acceptable but may cause surface scaling

Cost Comparison vs. Alternatives

| Material | Relative Cost (Index) | Max Temp | Corrosion Resistance | Notes |

|---|---|---|---|---|

| 409L Stainless | 1.0 (baseline) | 650°C | Moderate | Best value for exhaust systems |

| Aluminized Steel | 0.7 | 550°C | Low-Moderate | Cheaper but shorter lifespan |

| 304 Stainless | 2.0–2.5 | 870°C | High | Over-engineered for many exhaust uses |

| 439 Stainless | 1.4 | 800°C | Good | Used in premium/high-performance systems |

409L offers the lowest total cost of ownership in mid-range temperature applications.

Quality Assurance & Certification

Every batch undergoes:

- Spectrometric chemical analysis

- Tensile and hardness testing

- Ultrasonic or eddy current inspection (on request)

- Surface quality verification under ISO lighting standards

Mill Test Certificates (MTCs) per EN 10204 3.1 are provided, ensuring full traceability and compliance.

Environmental Impact

- 98% recyclable at end-of-life

- Enables lighter vehicle designs, reducing CO₂ emissions

- Eliminates need for frequent replacement → lower resource consumption

- Supports OEM sustainability targets (e.g., Ford’s “Carbon Neutral by 2050” initiative)

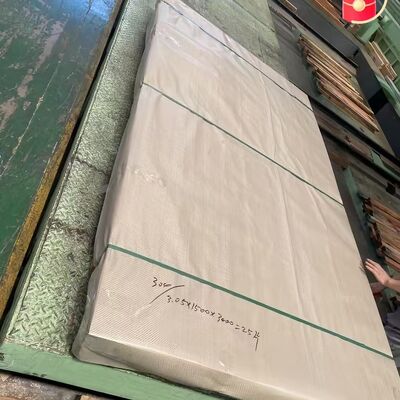

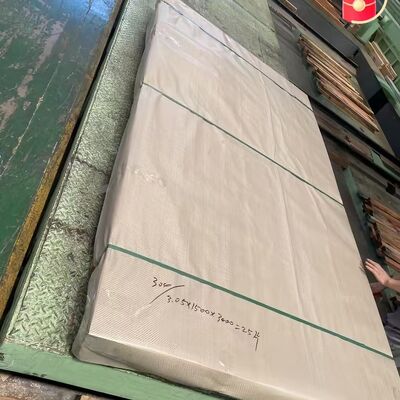

Packaging & Delivery

- Sheets/coils protected with VCI anti-corrosion paper

- Edges reinforced with plastic corner guards

- Palletized and strapped for secure inland or ocean transport

- Custom cutting (slitting, blanking, leveling) available

Standard Sizes:

- Width: 1000–1500 mm

- Length: 2000–6000 mm (or coil)

- Thickness: 0.3–12.0 mm (depending on process)

Conclusion

For engineers and procurement teams seeking a reliable, economical, and future-ready material for high-temperature environments, 409L ferritic stainless steel sheet stands unmatched. It bridges the gap between low-cost carbon steel and high-performance—but expensive—austenitic alloys, delivering proven durability, ease of fabrication, and regulatory compliance at an accessible price point.

Trusted by global automakers and industrial leaders for decades, 409L isn’t just a material—it’s a strategic advantage.

Contact us today for samples, technical support, or volume pricing—and build smarter, hotter, and more sustainably with 409L.

409L ferritic stainless steel sheet, cost-effective stainless steel for high temp, 409L exhaust material, titanium-stabilized stainless steel, S40903 stainless steel, automotive 409L sheet, high-temperature stainless steel, 409L vs 304 cost, ferritic stainless steel 409L, UNS S40903, JIS G 4305 409L, ASTM A240 409L, oxidation resistant stainless steel, low carbon stainless steel sheet.

Recommended Products