Todos los productos

-

Tira de acero inoxidable

-

Hoja de acero inoxidable

-

Placa de acero inoxidable

-

tubería de acero inoxidable

-

Barra de acero inoxidable

-

Bobina de acero galvanizada

-

Placa de acero

-

barra redonda de acero

-

aleación de níquel

-

Tubería de acero inconsútil

-

Haz de acero inoxidable

-

Hoja de la placa de cobre

-

Barra redonda de cobre

-

Raian IonescuCalidad material muy buena. tenemos cooperar más de 10 años. Negocian clases de las porciones de material de acero. Toda la calidad material buena. Ellos deber para toda la calidad material. Estamos acepillando para continuar cooperando con ellos en el futuro

Raian IonescuCalidad material muy buena. tenemos cooperar más de 10 años. Negocian clases de las porciones de material de acero. Toda la calidad material buena. Ellos deber para toda la calidad material. Estamos acepillando para continuar cooperando con ellos en el futuro

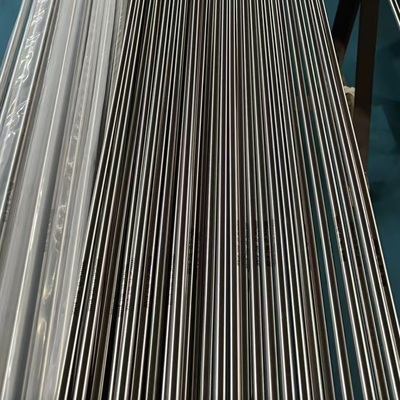

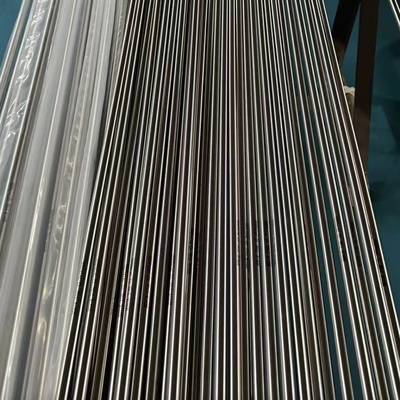

Hastelloy C276 Pipe Bright Annealed Precision Hollow Tube For Instruments And Apparatus

| Lugar de origen | China. |

|---|---|

| Nombre de la marca | DELTA |

| Certificación | ISO |

| Número de modelo | Hastelloy C276 |

| Cantidad de orden mínima | 10 kg |

| Precio | 40 - 50 USD/Kg |

| Detalles de empaquetado | Embalaje estándar para la exportación |

| Tiempo de entrega | 5 - 12 días basado en la cantidad |

| Condiciones de pago | L/C, T/T, Western Union |

| Capacidad de la fuente | 3 toneladas por semana |

Éntreme en contacto con gratis las muestras y los vales.

whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Si usted tiene alguna preocupación, proporcionamos ayuda en línea de 24 horas.

xDatos del producto

| Productos | Hastelloy C276 tuberías | Calificación | Hastelloy C276 |

|---|---|---|---|

| Diámetro | 6 - 219 mm | Longitud | corte personalizado de cualquier longitud a petición |

| Estándar | ASTM EN | SERVICIO | Corte |

| Puerto de carga | Puerto de Shanghai | Superficie | Brillante |

| Resaltar | Hastelloy C276 precision hollow tube,Bright annealed nickel alloy pipe,Hastelloy C276 instrument tubing |

||

Descripción de producto

Hastelloy C276 Pipe Bright Annealed Precision Hollow Tube For Instruments And Apparatus

More Specification Informations

| Products Name | Hastelloy C276 pipes |

| Diameter | 6.0 - 219mm |

| Thickness | 0.6 - 10.0mm |

| Length | custom cutting any length as request |

| Surface | bright |

| Brand | DELTA |

| Service | cutting, Polishing |

| MOQ | 2 Kgs |

| Other Type | round bar, strip,coil,pipe.sheet, plate,wire.etc |

| Packing | waterproof paper and wooden pallets, wooden box |

| Loading Port | Shanghai Port |

| Price term | EXW,FOB,CIF,CFR |

| Deliver time | within 12 days |

Hastelloy C276 Pipe Bright Annealed Precision Hollow Tube For Instruments And Apparatus

Hastelloy C276, a premium nickel-molybdenum-chromium alloy, is widely recognized for its exceptional corrosion resistance and mechanical stability in harsh operating environments. The bright annealed precision hollow tubes made from this alloy are specifically engineered to meet the stringent requirements of high-precision instruments and apparatus—such as analytical equipment, medical devices, and industrial measurement tools—where dimensional accuracy, surface quality, and resistance to aggressive media are non-negotiable. Below is a detailed breakdown of its key attributes, related grades, advantages, and extended product range.

1. Chemical Composition

Hastelloy C276’s superior performance stems from its carefully balanced chemical composition, which is standardized under international specifications (e.g., ASTM B575). The typical elemental range is as follows:

| Element | Content Range (%) | Key Function |

|---|---|---|

| Nickel (Ni) | 57.0 min | Base metal; provides fundamental corrosion resistance and alloy ductility. |

| Molybdenum (Mo) | 15.0 - 17.0 | Enhances resistance to pitting, crevice corrosion, and reducing acids (e.g., sulfuric acid). |

| Chromium (Cr) | 14.5 - 16.5 | Boosts resistance to oxidizing media (e.g., nitric acid) and high-temperature oxidation. |

| Iron (Fe) | 4.0 - 7.0 | Improves alloy workability and reduces cost without compromising corrosion resistance. |

| Tungsten (W) | 3.0 - 4.5 | Complements molybdenum to enhance resistance to localized corrosion (e.g., in chloride-rich environments). |

| Cobalt (Co) | 2.5 max | Controlled to minimize potential embrittlement and maintain alloy stability. |

| Carbon (C) | 0.01 max | Low carbon content prevents carbide precipitation during welding/heat treatment, avoiding intergranular corrosion. |

| Silicon (Si) | 0.08 max | Reduces oxide formation and improves casting/welding quality. |

| Manganese (Mn) | 1.0 max | Aids in deoxidation during manufacturing, ensuring material purity. |

2. Mechanical Properties

The bright annealed precision hollow tubes of Hastelloy C276 exhibit excellent mechanical properties, balancing strength and ductility—critical for instrument assembly and long-term service. The values below are based on the annealed condition (typical for precision tubes) and comply with ASTM B575 standards:

| Property | Test Standard | Typical Value | Unit |

|---|---|---|---|

| Tensile Strength (UTS) | ASTM E8 | ≥ 795 | MPa |

| Yield Strength (0.2% offset) | ASTM E8 | ≥ 310 | MPa |

| Elongation (in 50mm) | ASTM E8 | ≥ 40 | % |

| Hardness (Rockwell B) | ASTM E18 | ≤ 95 | HRB |

| Impact Toughness (Charpy V-notch, 23°C) | ASTM E23 | ≥ 120 | J |

Note: Bright annealing eliminates residual stresses from tube forming, improves surface finish (Ra ≤ 0.8 μm typically), and ensures consistent mechanical performance across the tube length—essential for precision instrument applications.

3. Similar Grades

Hastelloy C276 is part of a family of nickel-based superalloys, with several 相近牌号 (similar grades) designed for overlapping but distinct use cases. These grades are often interchangeable in non-critical applications but differ in specific properties (e.g., carbon content, minor alloying elements):

| Grade Name | Standard/Origin | Key Difference from C276 | Typical Application Overlap |

|---|---|---|---|

| Hastelloy C22 | ASTM B575 (Haynes) | Higher chromium (20-22%), lower molybdenum (12-14%); better resistance to oxidizing acids. | Chemical processing, instrument tubing. |

| Hastelloy C4 | ASTM B575 (Haynes) | Ultra-low carbon (≤ 0.009%), no tungsten; minimizes carbide precipitation in high-heat scenarios. | High-temperature chemical reactors, precision valves. |

| Inconel 625 | ASTM B163 (Special Metals) | Lower molybdenum (8-10%), added niobium (3.15-4.15%); better high-temperature strength. | Aerospace instruments, high-heat sensors. |

| Alloy 276 | EN 10088-1 (European) | Equivalent to Hastelloy C276; complies with EU standards for corrosion-resistant alloys. | European-based instrument manufacturing. |

4. Product Advantages for Instruments and Apparatus

The bright annealed precision hollow tubes of Hastelloy C276 are uniquely suited for instrument and apparatus applications, thanks to the following core advantages:

- Exceptional Corrosion Resistance: Resists a wide range of aggressive media—including strong acids (sulfuric, hydrochloric), alkalis, chloride solutions, and organic solvents—preventing tube degradation in analytical or medical instrument fluid pathways.

- Superior Dimensional Precision: Manufactured with tight tolerances (e.g., outer diameter tolerance ±0.05 mm, wall thickness tolerance ±0.02 mm) to ensure compatibility with small-scale instrument components (e.g., connectors, sensors).

- Bright Annealed Surface: The smooth, oxide-free surface (Ra ≤ 0.8 μm) reduces fluid friction, prevents sample contamination (critical for analytical instruments), and simplifies sterilization (for medical devices).

- Wide Temperature Adaptability: Maintains mechanical strength and corrosion resistance from cryogenic temperatures (-270°C) to high temperatures (up to 1093°C), suitable for instruments operating in extreme environments (e.g., industrial ovens, cryogenic sensors).

- Excellent Weldability: Can be welded using TIG/MIG methods without significant loss of corrosion resistance (when paired with low-carbon filler metals like ERNiCrMo-4), enabling easy integration into instrument assemblies.

5. Other Hastelloy C276 Products

Beyond precision hollow tubes, Hastelloy C276 is fabricated into a variety of products to support diverse industrial and instrument-related needs. These products share the alloy’s core corrosion resistance and mechanical stability:

- Sheet & Plate: Used for manufacturing instrument housings, reaction chambers, and sample holders—where flat, corrosion-resistant surfaces are required. Available in thicknesses from 0.5 mm to 100 mm, with bright or polished finishes.

- Wire & Wire Mesh: Applied in fine filters (for analytical sample preparation) or heating elements (in precision temperature-controlled instruments). Offered in diameters from 0.1 mm to 5 mm.

- Fittings & Valves: Includes compression fittings, ball valves, and check valves—designed to connect precision tubes in instrument fluid systems, ensuring leak-tight performance in corrosive environments.

- Fasteners: Bolts, nuts, and screws made from Hastelloy C276, used to assemble instrument components that require long-term resistance to chemical exposure (e.g., laboratory equipment).

- Custom Forgings: Tailored components (e.g., sensor casings, pump impellers) for specialized instruments, manufactured via forging to enhance material density and mechanical strength.

![]()

![]()

![]()

![]()

Productos recomendados