-

Raian IonescuΥλική ποιότητα πολύ υψηλή. πρέπει να συνεργαστούμε περισσότερο από 10 έτη. Ανταλλάσσουν τα είδη μερών υλικού χάλυβα. Όλο το υλικό ποιοτικό αγαθό. Αυτοί δασμός για όλη την υλική ποιότητα. Πλανίζουμε συνεχιζόμαστε συνεργαζόμαστε με τους στο μέλλον

Raian IonescuΥλική ποιότητα πολύ υψηλή. πρέπει να συνεργαστούμε περισσότερο από 10 έτη. Ανταλλάσσουν τα είδη μερών υλικού χάλυβα. Όλο το υλικό ποιοτικό αγαθό. Αυτοί δασμός για όλη την υλική ποιότητα. Πλανίζουμε συνεχιζόμαστε συνεργαζόμαστε με τους στο μέλλον

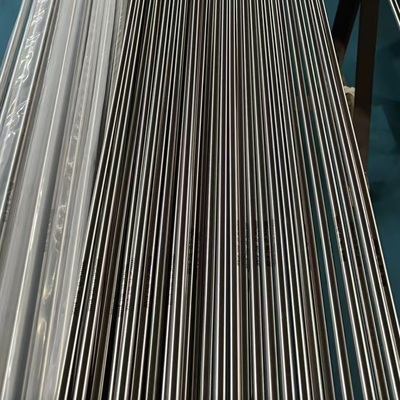

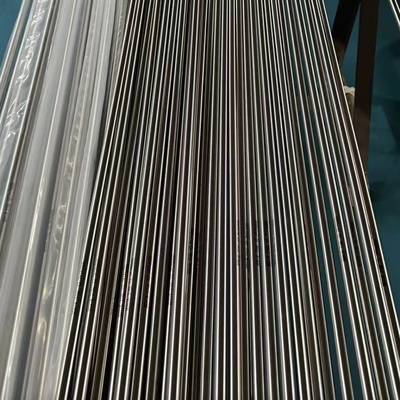

Hastelloy C276 Pipe Bright Annealed Precision Hollow Tube For Instruments And Apparatus

| Τόπος καταγωγής | Κίνα |

|---|---|

| Μάρκα | DELTA |

| Πιστοποίηση | ISO |

| Αριθμό μοντέλου | Hastelloy C276 |

| Ποσότητα παραγγελίας min | 10 κιλά |

| Τιμή | 40 - 50 USD/Kg |

| Συσκευασία λεπτομέρειες | τυπική συσκευασία για εξαγωγή |

| Χρόνος παράδοσης | 5 - 12 ημέρες με βάση την ποσότητα |

| Όροι πληρωμής | L/C, T/T, Western Union |

| Δυνατότητα προσφοράς | 3 τόνοι την εβδομάδα |

Με ελάτε σε επαφή με δωρεάν δείγματα και δελτία.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Εάν έχετε οποιαδήποτε ανησυχία, παρέχουμε τη 24ωρη σε απευθείας σύνδεση βοήθεια.

x| Προϊόντα | Hastelloy C276 σωλήνες | Βαθμός | Hastelloy C276 |

|---|---|---|---|

| Διάμετρος | 6 - 219mm | Μήκος | Προσαρμοσμένη κοπή οποιουδήποτε μήκους κατά παραγγελία |

| Στάνταρ | Astm en | ΥΠΗΡΕΣΙΑ | Τομή |

| Θύρα φόρτωσης | Λιμάνι της Σαγκάης | Επιφάνεια | Ευφυής |

| Επισημαίνω | Hastelloy C276 precision hollow tube,Bright annealed nickel alloy pipe,Hastelloy C276 instrument tubing |

||

Hastelloy C276 Pipe Bright Annealed Precision Hollow Tube For Instruments And Apparatus

More Specification Informations

| Products Name | Hastelloy C276 pipes |

| Diameter | 6.0 - 219mm |

| Thickness | 0.6 - 10.0mm |

| Length | custom cutting any length as request |

| Surface | bright |

| Brand | DELTA |

| Service | cutting, Polishing |

| MOQ | 2 Kgs |

| Other Type | round bar, strip,coil,pipe.sheet, plate,wire.etc |

| Packing | waterproof paper and wooden pallets, wooden box |

| Loading Port | Shanghai Port |

| Price term | EXW,FOB,CIF,CFR |

| Deliver time | within 12 days |

Hastelloy C276 Pipe Bright Annealed Precision Hollow Tube For Instruments And Apparatus

1. Chemical Composition

| Element | Content Range (%) | Key Function |

|---|---|---|

| Nickel (Ni) | 57.0 min | Base metal; provides fundamental corrosion resistance and alloy ductility. |

| Molybdenum (Mo) | 15.0 - 17.0 | Enhances resistance to pitting, crevice corrosion, and reducing acids (e.g., sulfuric acid). |

| Chromium (Cr) | 14.5 - 16.5 | Boosts resistance to oxidizing media (e.g., nitric acid) and high-temperature oxidation. |

| Iron (Fe) | 4.0 - 7.0 | Improves alloy workability and reduces cost without compromising corrosion resistance. |

| Tungsten (W) | 3.0 - 4.5 | Complements molybdenum to enhance resistance to localized corrosion (e.g., in chloride-rich environments). |

| Cobalt (Co) | 2.5 max | Controlled to minimize potential embrittlement and maintain alloy stability. |

| Carbon (C) | 0.01 max | Low carbon content prevents carbide precipitation during welding/heat treatment, avoiding intergranular corrosion. |

| Silicon (Si) | 0.08 max | Reduces oxide formation and improves casting/welding quality. |

| Manganese (Mn) | 1.0 max | Aids in deoxidation during manufacturing, ensuring material purity. |

2. Mechanical Properties

| Property | Test Standard | Typical Value | Unit |

|---|---|---|---|

| Tensile Strength (UTS) | ASTM E8 | ≥ 795 | MPa |

| Yield Strength (0.2% offset) | ASTM E8 | ≥ 310 | MPa |

| Elongation (in 50mm) | ASTM E8 | ≥ 40 | % |

| Hardness (Rockwell B) | ASTM E18 | ≤ 95 | HRB |

| Impact Toughness (Charpy V-notch, 23°C) | ASTM E23 | ≥ 120 | J |

3. Similar Grades

| Grade Name | Standard/Origin | Key Difference from C276 | Typical Application Overlap |

|---|---|---|---|

| Hastelloy C22 | ASTM B575 (Haynes) | Higher chromium (20-22%), lower molybdenum (12-14%); better resistance to oxidizing acids. | Chemical processing, instrument tubing. |

| Hastelloy C4 | ASTM B575 (Haynes) | Ultra-low carbon (≤ 0.009%), no tungsten; minimizes carbide precipitation in high-heat scenarios. | High-temperature chemical reactors, precision valves. |

| Inconel 625 | ASTM B163 (Special Metals) | Lower molybdenum (8-10%), added niobium (3.15-4.15%); better high-temperature strength. | Aerospace instruments, high-heat sensors. |

| Alloy 276 | EN 10088-1 (European) | Equivalent to Hastelloy C276; complies with EU standards for corrosion-resistant alloys. | European-based instrument manufacturing. |

4. Product Advantages for Instruments and Apparatus

- Exceptional Corrosion Resistance: Resists a wide range of aggressive media—including strong acids (sulfuric, hydrochloric), alkalis, chloride solutions, and organic solvents—preventing tube degradation in analytical or medical instrument fluid pathways.

- Superior Dimensional Precision: Manufactured with tight tolerances (e.g., outer diameter tolerance ±0.05 mm, wall thickness tolerance ±0.02 mm) to ensure compatibility with small-scale instrument components (e.g., connectors, sensors).

- Bright Annealed Surface: The smooth, oxide-free surface (Ra ≤ 0.8 μm) reduces fluid friction, prevents sample contamination (critical for analytical instruments), and simplifies sterilization (for medical devices).

- Wide Temperature Adaptability: Maintains mechanical strength and corrosion resistance from cryogenic temperatures (-270°C) to high temperatures (up to 1093°C), suitable for instruments operating in extreme environments (e.g., industrial ovens, cryogenic sensors).

- Excellent Weldability: Can be welded using TIG/MIG methods without significant loss of corrosion resistance (when paired with low-carbon filler metals like ERNiCrMo-4), enabling easy integration into instrument assemblies.

5. Other Hastelloy C276 Products

- Sheet & Plate: Used for manufacturing instrument housings, reaction chambers, and sample holders—where flat, corrosion-resistant surfaces are required. Available in thicknesses from 0.5 mm to 100 mm, with bright or polished finishes.

- Wire & Wire Mesh: Applied in fine filters (for analytical sample preparation) or heating elements (in precision temperature-controlled instruments). Offered in diameters from 0.1 mm to 5 mm.

- Fittings & Valves: Includes compression fittings, ball valves, and check valves—designed to connect precision tubes in instrument fluid systems, ensuring leak-tight performance in corrosive environments.

- Fasteners: Bolts, nuts, and screws made from Hastelloy C276, used to assemble instrument components that require long-term resistance to chemical exposure (e.g., laboratory equipment).

- Custom Forgings: Tailored components (e.g., sensor casings, pump impellers) for specialized instruments, manufactured via forging to enhance material density and mechanical strength.

![]()

![]()

![]()

![]()