-

Tira de acero inoxidable

-

Hoja de acero inoxidable

-

Placa de acero inoxidable

-

tubería de acero inoxidable

-

Barra de acero inoxidable

-

Bobina de acero galvanizada

-

Placa de acero

-

barra redonda de acero

-

aleación de níquel

-

Tubería de acero inconsútil

-

Haz de acero inoxidable

-

Hoja de la placa de cobre

-

Barra redonda de cobre

-

Raian IonescuCalidad material muy buena. tenemos cooperar más de 10 años. Negocian clases de las porciones de material de acero. Toda la calidad material buena. Ellos deber para toda la calidad material. Estamos acepillando para continuar cooperando con ellos en el futuro

Raian IonescuCalidad material muy buena. tenemos cooperar más de 10 años. Negocian clases de las porciones de material de acero. Toda la calidad material buena. Ellos deber para toda la calidad material. Estamos acepillando para continuar cooperando con ellos en el futuro

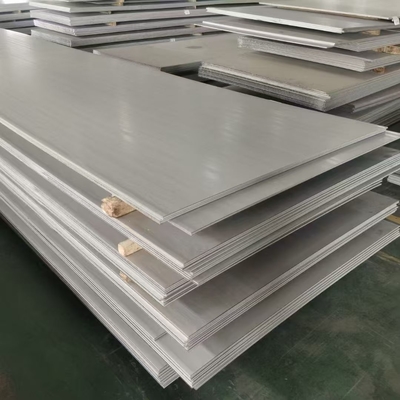

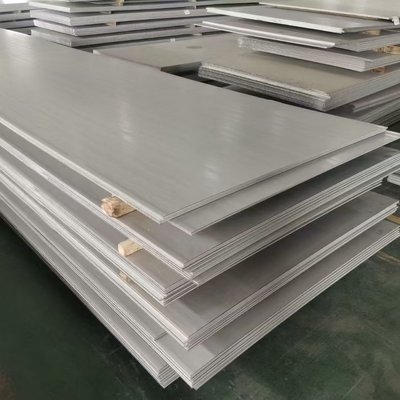

Placa de acero inoxidable 316 4x8 pies 5x20 pies 8x20 pies Laminada en frío Laminada en caliente

| Lugar de origen | China |

|---|---|

| Nombre de la marca | TISCO BAOSTEEL |

| Certificación | ISO |

| Número de modelo | 304 304L 316L 310S 321 2205 2507 904L 254SMO.etc |

| Cantidad de orden mínima | 500 kg |

| Precio | 5000 - 7200 USD/Ton |

| Detalles de empaquetado | Embalaje estándar para la exportación |

| Tiempo de entrega | 5 - 12 días en función de la cantidad |

| Condiciones de pago | T/T, Western Union |

| Capacidad de la fuente | 20 toneladas por semana |

Éntreme en contacto con gratis las muestras y los vales.

whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Si usted tiene alguna preocupación, proporcionamos ayuda en línea de 24 horas.

x| Productos | placa de acero inoxidable | Grado | 304 304L 316L 310S 321 2205 2507 904L 254SMO.etc |

|---|---|---|---|

| El grosor | 0.6 -80.0 mm | Ancho | 1219mm 1500mm 1800mm 2000mm |

| Superficie | NO.1 2B | Marca del producto | Baosteel Tisco |

| Estándar | Se aplicarán los siguientes requisitos: | Puerto de carga | Puerto de Shanghái |

| Resaltar | Las placas de chapa de acero inoxidable,Placas de acero inoxidable laminadas en frío,Hojas de acero inoxidables laminadas en caliente |

||

Placas de acero inoxidable 316 laminado en frío y laminado en caliente 4*8 pies 5*20 pies 8*20 pies Placas SS

Especificación de productos

| Nombre del producto | Placa de acero inoxidable 316 |

| Grados principales | Acero inoxidable J1, J2, J4, 201, 202, 301, 304, 304H, 304L, 309, 309S, 310, 310S, 316, 316L, 316TI, 317L, 321, 321H, 347, 409, 410, 410S, 420, 430, 441, 904L,630,631,254SMO,654SMO,253MA,2205,2507.etc |

| Espesor | 0.6 - 30.0mm |

| Ancho | 1250mm, 1500mm, 1800mm, 2000mm, u otro tamaño personalizado según la solicitud |

| Longitud | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, SEGÚN REQUERIMIENTO DEL CLIENTE |

| Servicio | Corte por láser |

| Forma | Placa / lámina |

| Forma de corte | Redonda, cuadrada o cualquier forma especial según la solicitud |

| Certificado de prueba | Sí. |

| Acabado | NO.1, 2B, 2D, 2H, 2R, No.4, HAIRLINE, SCOTCH BRITE, SATIN FINISH, NO.8, BA. |

| Marca | TISCO, LISCO, BAOSTEEL, POSCO, JISCO |

Distinguida por su resistencia a la corrosión mejorada con molibdeno, la lámina de acero inoxidable 316 es la aleación de trabajo para entornos exigentes donde el 304 estándar falla. Su principal ventaja radica en la resistencia a los cloruros, lo que la hace esencial para aplicaciones marinas, químicas e higiénicas.

Factores clave de rendimiento (vs. 304):

-

2-3% Molibdeno (Mo): Crítico para la resistencia a la corrosión por picaduras/hendiduras.

-

Variante de bajo carbono (316L): Previene la degradación de la soldadura (≤0.03% C).

-

No magnético (recocido): Adecuado para entornos electrónicos sensibles.

1. Parámetros de selección críticos y tolerancias

| Parámetro | Rango de valores 316 / 316L | Estándar clave | Enfoque de tolerancia (por ejemplo, ASTM A480) |

|---|---|---|---|

| PREN* | 24-28 | N/A | *Índice de corrosión crítico (Cr + 3.3Mo + 16N)* |

| Espesor (mm/in) | 0.3-6.0 / 0.012-0.236 | ASTM A480 | ±0.02mm (precisión) a ±10% (HR) |

| Ancho (mm/in) | 1000-2000 / 39-79 | EN 10029 | +5/-0 mm (borde cortado), +10/-0 mm (laminado) |

| Planitud (mm/m) | ≤3 (Laminado en frío) | ASTM A480 | Varía según el espesor y el ancho |

| Ra de la superficie (μm) | 0.1-0.5 (2B), <0.2 (BA) | ISO 4287 | Crítico para la higiene y la adhesión |

Número equivalente de resistencia a las picaduras – cuanto más alto, mejor resistencia a los cloruros.*

2. Matriz de especificaciones: Estándares x Requisitos clave

| Estándar | Grado | Área de enfoque clave | Prueba obligatoria (Ejemplo) |

|---|---|---|---|

| ASTM A240 | S31600/S31603 | Recipientes a presión y aplicaciones generales | Corrosión por picaduras (ASTM G48) |

| EN 10088-2 | 1.4401/1.4404 | Construcción y cumplimiento de la UE | Corrosión intergranular (ISO 3651-2) |

| JIS G4305 | SUS 316/SUS316L | Maquinaria industrial japonesa | Contenido de ferrita (JIS G 0567) |

| ASME SA-240 | S31600/S31603 | Código de calderas y recipientes a presión | Pruebas hidrostáticas / ultrasónicas |

| ISO 9328-2 | P316L | Equipos de presión internacionales | Resistencia al impacto (-196°C) |

3. Equivalentes globales y grados patentados

| Región | Grado estándar | Bajo carbono (L) | Estabilizado (Ti) | Variante de alto rendimiento |

|---|---|---|---|---|

| Global | UNS S31600 | UNS S31603 | UNS S31635 | UNS S31653 (Alto N) |

| Europa | 1.4401 (X5CrNiMo17-12-2) | 1.4404 | 1.4571 | 1.4436 (Mayor Mo+N) |

| Japón | SUS 316 | SUS 316L | SUS 316Ti | SUS 316J1L (N añadido) |

| China | 06Cr17Ni12Mo2 | 022Cr17Ni12Mo2 | 07Cr17Ni12Mo2Ti | 015Cr21Ni26Mo5Cu2 (Super) |

| India | 316S31 | 316S33 | 316S41 | - |

4. Protocolos de embalaje avanzados

| Nivel de protección | Método | Industrias atendidas | Impacto en el costo |

|---|---|---|---|

| Básico | Intercalado de papel VCI + flejes de acero | Fabricación general | +0% |

| Grado marino | Doble revestimiento de PE + paquetes desecantes | Offshore, construcción naval | +12-15% |

| Higiénico | Película PVF despegable + descarga de gas inerte | Farmacéutica, semiconductores | +20-30% |

| Alta abrasión | Protectores de esquinas + revestimiento de caja de madera contrachapada | Herramientas automotrices | +8-10% |

| Exportación pesada | Caja de madera reforzada con acero | Minería, proyectos remotos | +15-25% |

5. Aplicaciones especializadas y lógica de selección de aleaciones

| Industria | Requisito crítico | Subtipo 316 | ¿Por qué no 304? | Material competidor |

|---|---|---|---|---|

| Desalinización | Picaduras de agua salada a 60°C+ | 316L (2.5% Mo min) | PREN <20 insuficiente | Aleaciones de 6% Mo |

| Biotransformación | Corrosión CIP/SIP + pureza | 316L Espejo (#8) | Imperfecciones de la superficie | 316L electropulido |

| Arquitectura costera | Rociado de sal + estético | Acabado 316 HL | Manchas de óxido superficial | 2205 Dúplex |

| Cisternas químicas | Corrosión por vapor de carga | 316Ti | Sensibilización en soldaduras | Hastelloy |

| Sujetadores marinos | Corrosión por hendiduras | 316L (Trabajado en frío) | Picaduras galvánicas | Titanio |

6. Instantánea de especificaciones técnicas

| Propiedad | 316 (Recocido) | 316L (Recocido) | 316 (1/2 Duro) | Método de prueba |

|---|---|---|---|---|

| 0.2% Prueba (MPa) | 205 min | 170 min | 550 min | ASTM E8/E21 |

| UTS (MPa) | 515 min | 485 min | 860 min | ASTM E8/E21 |

| Alargamiento (%) | 40 | 40 | 12 | ASTM E8 (50mm GL) |

| Conductividad térmica (W/m·K) | 16.3 @100°C | 16.3 @100°C | 16.3 @100°C | ASTM C177 |

| CTE (μm/m·°C) | 16.0 (20-100°C) | 16.0 (20-100°C) | 16.0 (20-100°C) | ASTM E228 |

| Permeabilidad magnética | <1.02 μ | <1.02 μ | <1.10 μ | ASTM A342 |

Diferenciación clave del 304 estándar:

-

Umbral de cloruro: 316 resiste 200-1000 ppm Cl- vs. 50-100 ppm del 304

-

Temperatura de picaduras: 316 resiste hasta 25°C en 6% FeCl3 vs. 10°C del 304

-

Prima de costo: Típicamente 20-40% sobre el 304, justificado en servicio corrosivo

Consejo de adquisición: Especifique un contenido de Mo ≥2.1% para aplicaciones marinas y verifique que las certificaciones de fábrica cumplan con NACE MR0175/ISO 15156 para servicio agrio. Opte siempre por 316L para fabricaciones soldadas para evitar la corrosión intergranular.

![]()

![]()

![]()

![]()