All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

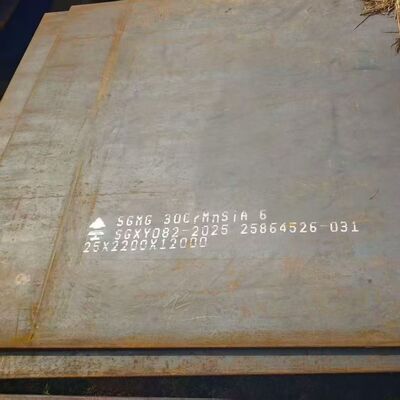

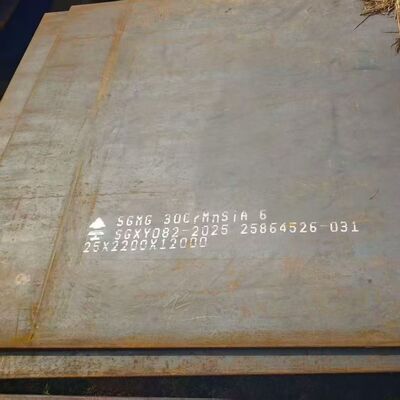

Hot Rolled 30CrMnSiA Alloy Steel Plate Thickness 10 - 200mm Custom Cutting As Request

| Place of Origin | China |

|---|---|

| Brand Name | BAOSTEEL BENSTEEL HBIS XINGCHENG |

| Certification | ISO 9001 |

| Model Number | 30CrMnSiA |

| Minimum Order Quantity | 10 kgs |

| Price | 540 - 890 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

Product Details

| Products | 30CrMnSiA | Thickness | 10.0 - 200.0mm |

|---|---|---|---|

| Width | 1000-2200mm | Length | 2000-12000mm |

| Standard | ASTM EN GB | Other Material | Carbon Steel, Alloy Steel, Stainless Steel |

| Brand | BAOSTEEL XINYU XINGCHENG HBIS | Service | Cutting |

Product Description

Hot Rolled 30CrMnSiA Alloy Steel Plate Thickness 10 - 200mm Custom Cutting As Request

Products Specification

| Product Name | 30CrMnSiA Alloy Steel Plate |

| Thickness | 10mm~200mm |

| Width | 1000~3000mm,common width is 1250mm,1500mm,2000mm,2200mm |

| Length | 1000~12000mm,can as your request cut |

| Surface | Clean,finished, blasting and painting or as your request |

| Delivery | Hot Rolled, Controlled Rolling,Normalizing,Annealing, Tempering,Quanching, Q+T |

| Packing | Steel Strapping,fixing in the Container,can customize |

| Thickness tolerance | ±0.3mm |

| Application | It is mainly used to make structural parts such as car girder, beam, transmission shaft and car chassis parts, which can reduce the weight of the parts. |

Hot Rolled 30CrMnSiA Alloy Steel Plate Thickness 10 – 200mm Custom Cutting As Request

Overview

Hot Rolled 30CrMnSiA Alloy Steel Plate is a high-performance, medium-carbon quenched and tempered structural steel widely used in demanding industrial applications such as aerospace, defense, automotive, heavy machinery, and oil & gas sectors. Known for its exceptional combination of high strength, good toughness, and excellent hardenability, 30CrMnSiA meets the stringent requirements of critical components that operate under high stress, impact, or fatigue conditions.

Manufactured to international standards including GB/T 11251-2009 (Chinese National Standard) and GJB 2150A-2005 (Military Specification), our hot-rolled 30CrMnSiA plates are available in thicknesses ranging from 10 mm to 200 mm, with full customization options for length, width, and precision cutting per your engineering drawings or specifications.

Key Features & Advantages

- High Tensile Strength: ≥1080 MPa after proper heat treatment

- Excellent Hardenability: Ideal for parts requiring deep section hardening

- Good Machinability: Responds well to CNC machining, milling, and drilling when properly annealed

- Controlled Impurities: Low sulfur (≤0.025%) and phosphorus (≤0.025%) ensure high purity and weld integrity

- Custom Cutting Services: Laser, plasma, or waterjet cutting available to exact dimensions

- Wide Thickness Range: From thin structural plates (10 mm) to heavy-duty blocks (200 mm)

- Consistent Quality: Produced via electric arc furnace + LF + VD refining for uniform microstructure

Note: While 30CrMnSiA offers good mechanical properties, it is classified as a medium-carbon alloy steel, which means preheating is essential before welding to avoid cold cracking. Post-weld stress relief is also recommended for critical applications.

Chemical Composition (Weight %)

| Element | Content (%) | Role in Performance |

|---|---|---|

| Carbon (C) | 0.28 – 0.34 | Provides core strength and hardness through martensitic transformation |

| Silicon (Si) | 0.90 – 1.20 | Enhances strength via solid solution strengthening; improves oxidation resistance |

| Manganese (Mn) | 0.80 – 1.10 | Increases hardenability and tensile strength; improves hot workability |

| Chromium (Cr) | 0.80 – 1.10 | Boosts hardenability, wear resistance, and corrosion resistance |

| Sulfur (S) | ≤ 0.025 | Strictly controlled to minimize hot shortness |

| Phosphorus (P) | ≤ 0.025 | Limited to prevent cold brittleness |

| Nickel (Ni) | ≤ 0.030 | Residual; kept low to maintain cost and performance balance |

| Copper (Cu) | ≤ 0.025 | Residual; controlled to avoid surface defects |

Note: Some premium grades may include trace Mo (0.10–0.30%) for enhanced temper stability.

Mechanical Properties (Typical Values After Quenching & Tempering)

| Property | Value | Test Standard |

|---|---|---|

| Tensile Strength (σb) | ≥ 1080 MPa | GB/T 228.1 |

| Yield Strength (σs) | ≥ 835 MPa | GB/T 228.1 |

| Elongation (δ5) | ≥ 10% | GB/T 228.1 |

| Reduction of Area (ψ) | ≥ 45% | GB/T 228.1 |

| Impact Toughness (Akv, 20°C) | ≥ 39 J | GB/T 229 |

| Impact Toughness (Akv, -40°C) | ≥ 88 J (premium grade) | GB/T 229 |

| Hardness (HB) | ≤ 229 (as-rolled); 24–32 HRC (after Q&T) | GB/T 231.1 |

Performance may vary slightly based on plate thickness and heat treatment parameters.

Available Dimensions & Tolerances

| Parameter | Range |

|---|---|

| Thickness | 10 mm – 200 mm |

| Width | 1000 mm – 3000 mm (standard); custom up to 3500 mm |

| Length | 2000 mm – 12000 mm (standard); longer lengths on request |

| Thickness Tolerance | ±0.5 mm (for 10–50 mm); ±1.0 mm (50–100 mm); ±2.0 mm (>100 mm) per GB/T 709 |

| Flatness | ≤ 5 mm/m (Class N); tighter tolerances available upon request |

| Surface Finish | Hot-rolled black scale (standard); shot-blasted or pickled optional |

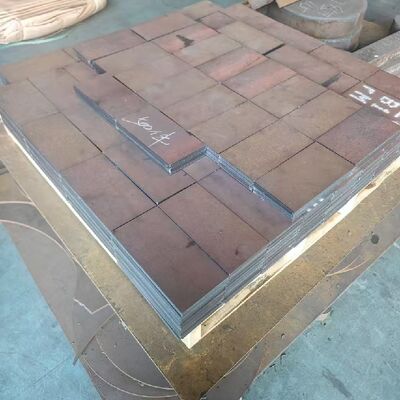

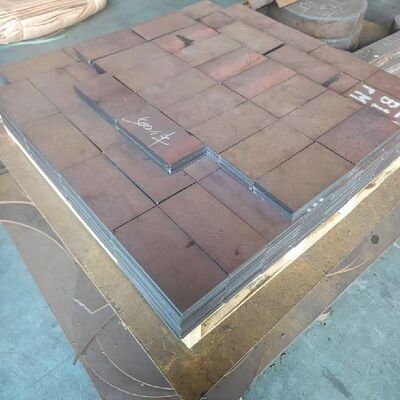

Custom Cutting Services

We offer precision cutting tailored to your project needs:

- Laser Cutting: For intricate shapes (up to 25 mm thick)

- Plasma Cutting: Cost-effective for medium-thickness plates (10–80 mm)

- Waterjet Cutting: Cold-cutting process ideal for maintaining material integrity (up to 200 mm)

- Flame Cutting: For heavy sections (>50 mm) with minimal thermal distortion

- CNC Machining: Drilling, milling, beveling, and edge preparation available

All cut parts are deburred, marked with heat number, and packaged for safe shipment.

Common Applications

| Industry | Typical Components |

|---|---|

| Aerospace | Landing gear brackets, engine mounts, structural frames |

| Defense & Military | Armor components, weapon systems, vehicle chassis |

| Automotive | Crankshafts, connecting rods, transmission gears |

| Heavy Machinery | Excavator booms, hydraulic cylinders, gear housings |

| Oil & Gas | High-pressure valves, drill collars, downhole tools |

| Rail & Transportation | Axles, couplers, suspension arms |

Thanks to its balanced strength-toughness profile, 30CrMnSiA is often selected where failure is not an option.

Heat Treatment Recommendations

For optimal performance, the following heat treatment cycle is recommended:

- Normalizing: 880–900°C, air cool (to refine grain structure)

- Quenching: 860–880°C, oil quench

- Tempering: 500–600°C, air cool (adjust based on required hardness)

Avoid tempering between 250–400°C to prevent temper brittleness.

Packaging & Delivery

- Plates are bundled with steel straps and protected with anti-rust paper

- Edges wrapped with plastic or wood to prevent damage during transit

- Marked with grade, heat number, dimensions, and compliance certificates

- Export-ready packaging (fumigated wooden pallets or crates available)

- Lead time: 7–25 days depending on size and quantity

- Global shipping via sea, air, or rail from major Chinese ports (Shanghai, Tianjin, Qingdao)

Why Choose Our 30CrMnSiA Plates?

✅ Mill-Direct Supply – No middlemen, competitive pricing

✅ Full Traceability – Each batch comes with Mill Test Certificate (EN 10204 3.1)

✅ Quality Assurance – ISO 9001 certified production; ultrasonic testing (UT) available per ASTM A578

✅ Technical Support – Our metallurgical engineers assist with material selection and processing advice

✅ Flexible MOQ – From single plates to bulk contracts

✅ Full Traceability – Each batch comes with Mill Test Certificate (EN 10204 3.1)

✅ Quality Assurance – ISO 9001 certified production; ultrasonic testing (UT) available per ASTM A578

✅ Technical Support – Our metallurgical engineers assist with material selection and processing advice

✅ Flexible MOQ – From single plates to bulk contracts

Frequently Asked Questions (FAQ)

Q: Is 30CrMnSiA weldable?

A: Yes, but with precautions. Preheat to 200–300°C, use low-hydrogen electrodes, and perform post-weld heat treatment (PWHT) if required.

A: Yes, but with precautions. Preheat to 200–300°C, use low-hydrogen electrodes, and perform post-weld heat treatment (PWHT) if required.

Q: What’s the difference between 30CrMnSi and 30CrMnSiA?

A: The “A” denotes higher purity—lower P, S, and residual elements—making it suitable for critical aerospace and military uses.

A: The “A” denotes higher purity—lower P, S, and residual elements—making it suitable for critical aerospace and military uses.

Q: Can you supply certified material for ASME or EN projects?

A: While 30CrMnSiA is a Chinese grade, we can provide cross-reference data (e.g., similar to AISI 4130/4140 in performance) and full chemical/mechanical reports for approval.

A: While 30CrMnSiA is a Chinese grade, we can provide cross-reference data (e.g., similar to AISI 4130/4140 in performance) and full chemical/mechanical reports for approval.

Q: Do you offer surface treatments?

A: Yes—options include shot blasting, painting, galvanizing, or oil coating for temporary corrosion protection.

A: Yes—options include shot blasting, painting, galvanizing, or oil coating for temporary corrosion protection.

30CrMnSiA steel plate, hot rolled alloy steel plate, high strength steel plate 10-200mm, custom cut 30CrMnSiA, quenched and tempered steel plate, GB/T 11251 steel, aerospace alloy steel, military grade steel plate, 30CrMnSiA mechanical properties, China 30CrMnSiA supplier, precision cut alloy steel, heavy plate cutting service.

Recommended Products