All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

SUS304 Stainless Steel Strip Cold Rolled 2B 0.1-3.0MM Thickness Precision Cutting Without Burr

| Place of Origin | China |

|---|---|

| Brand Name | TISCO BAOSTEEL POSCO |

| Certification | ISO |

| Model Number | 201 304 309S 310S 316L 317L 321 347 410 420 430.etc |

| Minimum Order Quantity | 2 Ton |

| Price | 1800-2000 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

Product Details

| Products | Stainless Steel Coil | Material | Stainless Steel |

|---|---|---|---|

| Thickness | 0.1 - 3.0mm | Width | 1000mm 1219mm 1500mm |

| Surface | 2B NO.1 NO.4 8K | Grade | 201 304 309S 310S 316L 317L 321 347 410 420 430 436 439 441 444.etc |

| Standard | ASTM EN GB JIS | Service | Cutting |

| Highlight | SUS304 stainless steel strip,cold rolled stainless steel strip,precision cut stainless steel strip |

||

Product Description

SUS304 Stainless Steel Strip Cold Rolled 2B 0.1-3.0MM Thickness Precision Cutting Without Burr

Products Specification

|

Products Name:

|

Stainless steel Coil

|

|||

|

Thickness:

|

0.1 mm - 10.0 mm

|

|||

|

Inner Diameter

|

508mm

|

|||

|

Width:

|

1000mm, 1219mm, customized max width 1500mm

|

|||

|

SS Grade:

|

201 202 301 304 304L 309S 310S 316L 316Ti 317L 409L 410 420 436L 439 441 444

2205 2507 904L C276 600 625 825 926.etc

|

|||

|

Coil surfaces:

|

2B, No.1, BA, Mirror, Hairline, No.4, PVD

|

|||

|

Available finishes:

|

No.4, Hairline, Mirror, Etching, PVD Color, Embossed, Vibration, Sandblast, Combination, lamination etc.

|

|||

|

Standard:

|

JIS, AISI,ASTM,GB,DIN

|

|||

|

Packing way:

|

PVC+ waterproof paper + strong sea-worthy wooden package

|

|||

SUS304 Stainless Steel Strip Cold Rolled 2B 0.1–3.0mm Thickness – Precision Cut Without Burr

Overview

SUS304 stainless steel strip, cold rolled with a 2B surface finish and available in thicknesses ranging from 0.1 mm to 3.0 mm, is one of the most widely used austenitic stainless steel products in industrial and commercial applications. Renowned for its excellent corrosion resistance, formability, weldability, and aesthetic appeal, SUS304 (equivalent to AISI 304 or EN 1.4301) serves as the benchmark material across sectors such as electronics, automotive, medical devices, food processing, architecture, and precision engineering.

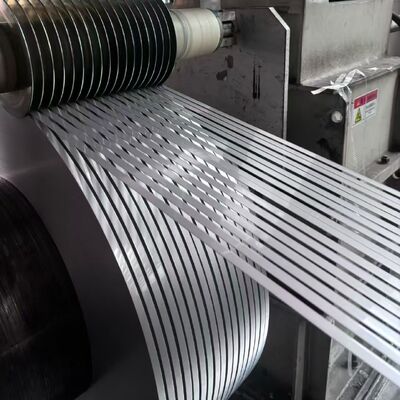

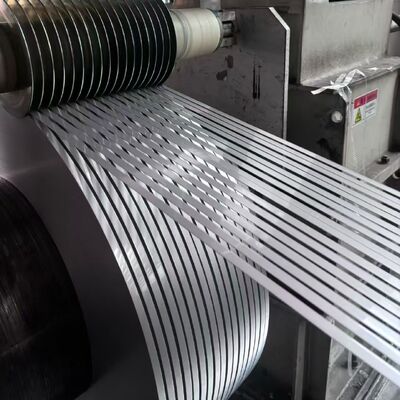

Our precision-cut SUS304 stainless steel strips are manufactured under strict quality control standards to ensure zero burr edges, consistent dimensional tolerances, and superior surface integrity—critical for high-precision assembly and automated production lines.

Key Features & Benefits

- Material Grade: SUS304 (JIS), AISI 304, EN 1.4301

- Surface Finish: 2B (standard mill finish – smooth, semi-bright, suitable for further polishing)

- Thickness Range: 0.1 mm to 3.0 mm (customizable within range)

- Width Options: 5 mm to 600+ mm (slit-to-width per customer specification)

- Edge Quality: Precision slitting with no burrs, ideal for sensitive applications

- Tolerance Control: ±0.005 mm on thickness (for thin gauges <0.5 mm), ±0.02 mm for thicker strips

- Certifications: ISO 9001, RoHS compliant, Material Test Reports (MTR/EN 10204 3.1) available

- Packaging: Anti-rust paper, plastic film, wooden pallets – moisture-proof and coil-protected

This product is especially valued in industries where cleanliness, reliability, and repeatability are non-negotiable—such as semiconductor manufacturing, surgical instruments, battery components, and sensor housings.

Chemical Composition (Per JIS G4305)

| Element | Content (%) – Max/Min |

|---|---|

| Carbon (C) | ≤ 0.08 |

| Manganese (Mn) | ≤ 2.00 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.030 |

| Silicon (Si) | ≤ 1.00 |

| Chromium (Cr) | 18.0 – 20.0 |

| Nickel (Ni) | 8.0 – 10.5 |

| Iron (Fe) | Balance |

This balanced composition ensures optimal austenitic structure, delivering high ductility, non-magnetic properties (in annealed condition), and resistance to oxidation and organic acids.

Mechanical Properties (Typical, Annealed Condition)

| Property | Value |

|---|---|

| Tensile Strength | 515–690 MPa |

| Yield Strength (0.2% offset) | ≥ 205 MPa |

| Elongation | ≥ 40% |

| Hardness (HV) | 150–200 |

| Density | 7.93 g/cm³ |

| Melting Point | 1400–1450°C |

These properties make SUS304 strips highly suitable for deep drawing, bending, stamping, and laser cutting without cracking or work hardening issues—especially when processed with proper tooling.

Surface Finish: What Is 2B?

The 2B finish is achieved through cold rolling, heat treatment, pickling, and a final light skin-pass rolling. It offers:

- A uniform, matte-silver appearance

- Better flatness and smoother surface than No.1 or 2D finishes

- Excellent base for additional polishing (e.g., to BA, 8K, or brushed finishes)

- Ideal for applications requiring both functionality and visual appeal

Unlike abrasive finishes (e.g., No.4), 2B minimizes surface defects that could harbor contaminants—making it food-grade and medical-device compliant when paired with proper cleaning protocols.

Precision Cutting Without Burrs: Why It Matters

In high-speed automation or micro-component fabrication, even microscopic burrs can cause:

- Assembly jams

- Electrical shorts (in battery tabs or connectors)

- Contamination in cleanrooms

- Reduced fatigue life in dynamic parts

Our advanced tungsten-carbide slitting lines and post-processing deburring systems ensure edge smoothness down to Ra ≤ 0.8 µm, verified by optical profilometry. Every coil undergoes 100% edge inspection before shipment.

Common Applications

| Industry | Use Cases |

|---|---|

| Electronics | Battery tabs, EMI shielding, flexible circuits, connector springs |

| Medical | Surgical blades, implant components, diagnostic device parts |

| Automotive | Fuel injector components, sensor brackets, gaskets |

| Food & Beverage | Conveyor belts, filling nozzles, hygiene panels |

| Aerospace | Fasteners, brackets, thermal shields |

| Renewable Energy | Solar frame clips, fuel cell bipolar plates |

Technical Specifications Summary

| Parameter | Specification |

|---|---|

| Grade | SUS304 (JIS), AISI 304, 1.4301 |

| Form | Cold Rolled Strip / Coil |

| Thickness | 0.1 mm – 3.0 mm |

| Width | 5 mm – 650 mm (custom slit widths available) |

| Length | In coil (ID: 200/300/500 mm; OD up to 1200 mm) or cut-to-length |

| Surface | 2B (standard); optional: BA, No.4, HL upon request |

| Edge Type | Slit edge, deburred, no micro-burrs |

| Tolerance (Thickness) | ±0.005 mm (0.1–0.5 mm), ±0.02 mm (0.5–3.0 mm) |

| Flatness | ≤ 1.0 I-Unit (for thin strips <0.3 mm) |

| Standards | JIS G4305, ASTM A666, EN 10088-2 |

| Packaging | VCI paper + PE film + steel pallet, export-ready |

Quality Assurance & Traceability

Every batch of our SUS304 stainless steel strip is fully traceable via heat number. We provide:

- Mill Test Certificates (MTC) per EN 10204 3.1

- Spectrometric analysis reports

- Dimensional inspection records

- Surface quality photos (upon request)

Our production facilities are equipped with online thickness gauges, laser micrometers, and eddy current testers to guarantee consistency across thousands of meters of coil.

Why Choose Our SUS304 Precision Strips?

- Zero-Burr Guarantee: Critical for automated assembly and safety-critical parts.

- Tight Tolerances: Meet ISO 2178 and ASTM E29 standards.

- Global Compliance: Meets EU, US, and Japanese regulatory requirements.

- Flexible MOQ: From 50 kg for prototyping to container loads for OEMs.

- Fast Lead Time: 7–15 days for standard sizes; expedited options available.

We support just-in-time (JIT) delivery and offer kitted sets for multi-thickness projects.

Frequently Asked Questions (FAQ)

Q: Is SUS304 magnetic?

A: In the annealed state, it’s generally non-magnetic. Cold working may induce slight magnetism, but it remains below 10 Gauss in most cases.

A: In the annealed state, it’s generally non-magnetic. Cold working may induce slight magnetism, but it remains below 10 Gauss in most cases.

Q: Can you supply strips with a protective film?

A: Yes—anti-scratch PE film (30–50 µm) can be applied on one or both sides.

A: Yes—anti-scratch PE film (30–50 µm) can be applied on one or both sides.

Q: What’s the minimum order quantity?

A: As low as 50 kg for standard dimensions; custom widths may require 200–500 kg.

A: As low as 50 kg for standard dimensions; custom widths may require 200–500 kg.

Q: Do you offer 304L or 316L in the same format?

A: Absolutely. We stock and process multiple grades including 301, 304L, 316, 316L, and 430.

A: Absolutely. We stock and process multiple grades including 301, 304L, 316, 316L, and 430.

Conclusion

For engineers, procurement managers, and product designers seeking a reliable, high-performance stainless steel strip that combines corrosion resistance, precision geometry, and burr-free edges, our SUS304 Cold Rolled 2B Strip (0.1–3.0 mm) delivers unmatched value. Backed by rigorous quality systems and global logistics support, we ensure your production line never stops due to material defects.

Contact us today for samples, technical data sheets, or a custom quote—optimized for your application’s exact requirements.

SUS304 stainless steel strip, cold rolled 304 stainless steel, 2B finish stainless coil, precision slit stainless steel, burr-free stainless strip, 0.1mm stainless steel tape, 304 stainless steel 2B, JIS G4305 compliant, stainless steel strip for electronics, medical grade 304 strip, no burr stainless coil, thin gauge stainless steel, 304 stainless steel 0.5mm, high tolerance stainless strip.

Recommended Products