-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

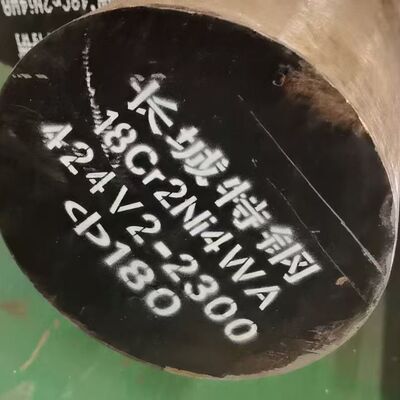

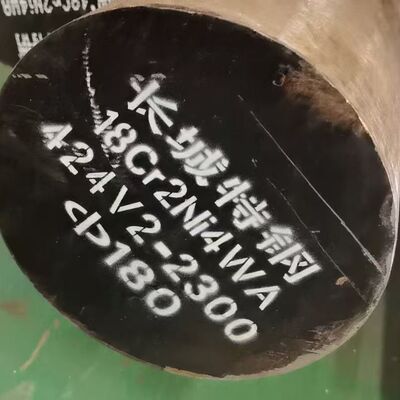

Hot Rolled and Forged 18Cr2Ni4WA Alloy Steel Round Bar Structure Application Diameter 20 - 300mm

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products Name | Alloy Steel Round Bar | Diameter | 10 - 450mm |

|---|---|---|---|

| Length | 6m | Tech | Hot Rolled |

| Service | Cutting | MOQ | 1 Ton |

| Loading Port | Shanghai Port | Standard | ASTM EN GB |

Hot Rolled and Forged 18Cr2Ni4WA Alloy Steel Round Bar Structure Application Diameter 20 - 300mm

Products Specification

|

Products Name |

18Cr2Ni4WA Alloy Steel Round Bar |

|

Diameter |

20 - 350 mm |

|

Length |

6m or custom cutting any length as request |

|

Type |

Hot Rolled |

|

Brand |

BAOSTEEL DELTA DONGBEI HUAXI SHAGANG.etc |

|

MOQ |

1 Ton |

|

Loading Port |

Shanghai Port |

|

Packing |

packing by steel wire rope |

|

Deliver time |

5 - 7 days for stock materials |

|

Other Grade |

Q195,Q235,10#,20#,35#,45#,Q215,Q345,12Cr1Mov,15CrMo ,20Cr,40Cr,20CrMo,35CrMo,42CrMo,40CrNiMo,GCr15,65Mn,50Mn, 50Cr,3Cr2W8V,20CrMnTi,25Cr2MoVA,5CrMnMo ,38CrMoAl, 30CrMnSiA,B16,31CrMoV9 |

|

Standard |

ASTM GB EN DIN |

|

Application |

Structure and Industrial |

Hot Rolled and Forged 18Cr2Ni4WA Alloy Steel Round Bar Structure Application Diameter 20 - 300mm

Introduction to 18Cr2Ni4WA Alloy Steel Round Bar

18Cr2Ni4WA is a high-strength, high-durability alloy steel commonly used in various structural applications. The alloy composition includes Chromium (Cr), Nickel (Ni), and Molybdenum (Mo), which endow the steel with exceptional mechanical properties. Hot rolled and forged 18Cr2Ni4WA alloy steel round bars with diameters ranging from 20mm to 300mm are widely utilized in industries requiring robust materials capable of withstanding heavy mechanical stress, corrosion, and high-temperature environments.

This alloy steel is particularly renowned for its excellent performance in applications such as machinery manufacturing, heavy-duty equipment, automotive components, and aerospace engineering. The steel is produced through advanced forging and hot rolling processes, which significantly enhance its strength, fatigue resistance, and overall reliability.

Chemical Composition

The key elements that make up the 18Cr2Ni4WA alloy steel are:

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.18 - 0.22 |

| Chromium (Cr) | 1.8 - 2.2 |

| Nickel (Ni) | 3.8 - 4.2 |

| Molybdenum (Mo) | 0.2 - 0.4 |

| Silicon (Si) | 0.3 - 0.6 |

| Manganese (Mn) | 0.5 - 0.8 |

| Phosphorus (P) | ≤ 0.035 |

| Sulfur (S) | ≤ 0.035 |

| Tungsten (W) | 0.4 - 0.7 |

This unique combination of alloying elements provides excellent toughness, wear resistance, and high-temperature stability.

Mechanical Properties

The mechanical properties of 18Cr2Ni4WA alloy steel round bars can be summarized as follows:

| Property | Value |

|---|---|

| Tensile Strength | 800 - 1000 MPa |

| Yield Strength | 650 - 850 MPa |

| Elongation | ≥ 15% |

| Hardness (HB) | 250 - 300 |

| Impact Toughness | ≥ 30 J at -20°C |

| Modulus of Elasticity | 200 GPa |

These mechanical properties ensure that the 18Cr2Ni4WA alloy steel is capable of withstanding high levels of stress and wear while maintaining structural integrity under extreme conditions. The tensile strength, yield strength, and impact toughness make it ideal for use in critical structural and engineering applications where reliability is essential.

Applications of 18Cr2Ni4WA Alloy Steel Round Bars

The versatility and superior mechanical properties of 18Cr2Ni4WA alloy steel make it suitable for a variety of structural and engineering applications. Some of the most common uses include:

-

Automotive Industry:

-

Manufacturing of engine components, drive shafts, and gears.

-

Production of high-performance suspension parts, bearing housings, and crankshafts.

-

-

Aerospace Industry:

-

Aircraft landing gear components, turbine engine parts, and structural components.

-

Parts requiring high tensile strength and resistance to fatigue and high temperatures.

-

-

Heavy Machinery and Equipment:

-

Construction machinery such as bulldozer blades, excavator arms, and hydraulic cylinders.

-

Mining equipment and other high-load bearing components.

-

-

Mechanical Engineering:

-

Shafts, axles, and couplings that require high mechanical strength and resistance to wear and tear.

-

Gear shafts and other rotating equipment parts.

-

-

Oil and Gas Industry:

-

Drill bits, wellheads, and other critical components exposed to high pressure and extreme environments.

-

-

Railroad Industry:

-

Railway axles, wheels, and rail components, requiring high strength and wear resistance.

-

Production Process: Hot Rolling and Forging

Hot Rolling:

Hot rolling is a manufacturing process where metal is heated above its recrystallization temperature and then passed through rollers to achieve the desired shape. The process results in improved mechanical properties and the production of a smooth surface. The diameter range for hot-rolled 18Cr2Ni4WA alloy steel bars typically spans from 20mm to 300mm, making it versatile for a wide range of structural applications.

Forging:

Forging involves shaping the alloy steel by applying compressive forces. This method refines the grain structure of the material, leading to superior mechanical properties. Forged 18Cr2Ni4WA round bars are commonly used in high-stress applications due to their enhanced strength, resistance to fatigue, and superior structural integrity.

Key Advantages of Hot Rolled and Forged 18Cr2Ni4WA Alloy Steel

-

Enhanced Strength: The combination of chromium, nickel, and molybdenum increases the tensile strength, making the alloy ideal for heavy-duty applications.

-

Improved Toughness: The alloy’s superior impact toughness ensures that it can endure extreme stresses and environmental conditions without cracking.

-

Corrosion Resistance: The chromium content offers enhanced resistance to corrosion and oxidation, making the material suitable for use in aggressive environments.

-

Heat Resistance: This alloy can withstand high operating temperatures, making it ideal for applications where heat resistance is crucial.

-

Wear Resistance: The steel exhibits excellent wear resistance, ensuring longevity and reduced maintenance costs for industrial machinery.

Size Range and Customization

18Cr2Ni4WA alloy steel round bars are available in a wide range of diameters, from 20mm to 300mm. The size can be customized according to the requirements of specific applications. Whether used for manufacturing shafts, gears, or heavy-duty components, the versatility of this steel in terms of size makes it suitable for various engineering needs.

Comparison with Other Alloy Steels

When compared to other similar alloy steels, 18Cr2Ni4WA offers several advantages:

| Alloy Steel | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Corrosion Resistance |

|---|---|---|---|---|

| 18Cr2Ni4WA | 800 - 1000 | 650 - 850 | 250 - 300 | Excellent |

| 4140 | 670 - 1050 | 415 - 655 | 200 - 250 | Good |

| 4340 | 745 - 1,015 | 565 - 725 | 230 - 280 | Good |

| 8620 | 610 - 825 | 415 - 575 | 180 - 240 | Fair |

As seen in the table above, 18Cr2Ni4WA has higher tensile strength and yield strength than common alloy steels like 4140, 4340, and 8620, making it a superior choice for high-stress applications.

Conclusion

The 18Cr2Ni4WA alloy steel round bar, offered in diameters ranging from 20mm to 300mm, is an essential material for demanding industrial applications requiring high mechanical strength, wear resistance, and heat resistance. Produced through hot rolling and forging, this steel demonstrates exceptional toughness, corrosion resistance, and reliability in challenging environments. Whether used in the automotive, aerospace, or heavy machinery industries, 18Cr2Ni4WA alloy steel is the go-to choice for engineers seeking durable and high-performance materials.

![]()

![]()

![]()

![]()

![]()