-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

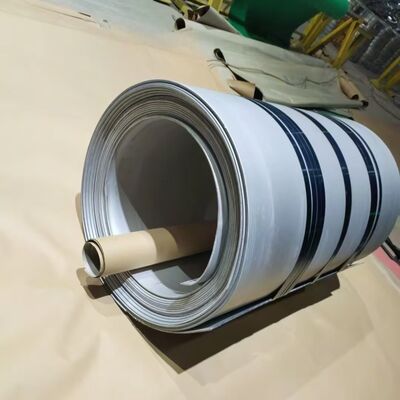

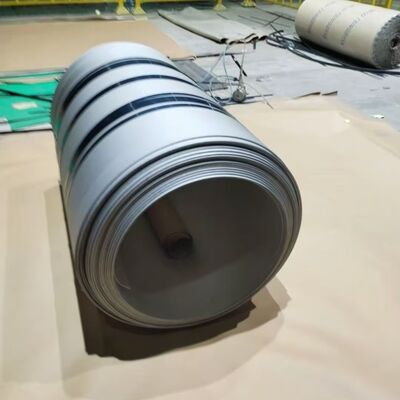

Premium Inconel 625 Nickel Alloy Plate and Sheet High-Temperature Corrosion Resistant

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products | Nickel Alloy Sheet & Plate | Grade | Inconel 625 |

|---|---|---|---|

| Thickness | 0.5 - 30.0mm | Standard Size | 1000*2000mm 1219*2438mm |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | 2B NO.1 |

| Highlight | Inconel 625 nickel alloy plate,High-temperature resistant nickel alloy sheet,Corrosion resistant Inconel 625 sheet |

||

Premium Inconel 625 Nickel Alloy Plate and Sheet High-Temperature Corrosion Resistant

Products Specification

| Products Name | Inconel 625 Nickel Alloy Sheet Plate |

| Thickness | Cold rolled: 0.5 - 3.0mm Hot rolled 4.0 - 30.0mm |

| Standard Size | 1000*2000mm 1219*2438mm 1219*3048mm 1500*6000mm |

| Surface | 2B NO.1 |

| MOQ | 50 kgs |

| Service | Cutting, Surface Finishing |

| Packing | Waterproof paper and wooden pallets |

| Loading Port | Shanghai Port |

| Price term | FOB CFR CIF EXW |

| Payment term | 30% TT in advance , 70% TT balance against copy of B/L |

| Main Grade | Hastelloy C22 C4 X C276 G35 |

| Monel 400 K500 | |

| Incoloy 800 800H 800HT 825 925 | |

| Inconel 600 601 617 625 716 718 | |

| Stainless Steel Grade | 201 202 301 304L 309S 310S 316L 316Ti 317L 321 347 409L 410 410S 420J1 420J2 430 431 436L 439 440A/B/C 441 443 444 2205 2507 904L 254SMO 253MA |

Premium Inconel 625 Nickel Alloy Plate and Sheet – High-Temperature Corrosion Resistant

Overview

Inconel 625 (UNS N06625) is a premium nickel-chromium-molybdenum-niobium alloy renowned for its exceptional resistance to high-temperature oxidation, corrosion in aggressive chemical environments, and outstanding mechanical strength across a wide temperature range—from cryogenic conditions up to 980°C (1800°F). Engineered for the most demanding industrial applications, Inconel 625 plate and sheet deliver unmatched reliability in extreme thermal, corrosive, and mechanical stress conditions.

Manufactured to meet stringent international standards—including ASTM B443, ASME SB-443, AMS 5599, and EN 10088—our Inconel 625 flat products are ideal for aerospace, marine engineering, chemical processing, nuclear energy, and power generation sectors where failure is not an option.

Key Features & Benefits

- Superior Corrosion Resistance: Exceptional performance in chloride-rich, acidic, and oxidizing environments—including seawater, hydrochloric acid, sulfuric acid, and mixed acid solutions.

- High-Temperature Strength: Maintains structural integrity and mechanical properties at temperatures up to 980°C (1800°F).

- Excellent Fabricability & Weldability: Can be readily formed, machined, and welded without post-weld cracking or loss of corrosion resistance.

- Outstanding Thermal Shock Resistance: Low coefficient of thermal expansion combined with high thermal conductivity minimizes stress during rapid temperature changes.

- Solid-Solution Strengthened: Molybdenum and niobium provide robust strengthening without requiring precipitation hardening.

- Certified for Critical Applications: Compliant with NACE MR0175/ISO 15156 for sour service environments and approved for pressure vessel use per ASME Section VIII.

Typical Chemical Composition (Weight %)

| Element | Minimum (%) | Maximum (%) |

|---|---|---|

| Nickel (Ni) | Balance | — |

| Chromium (Cr) | 20.0 | 23.0 |

| Molybdenum (Mo) | 8.0 | 10.0 |

| Niobium + Tantalum (Nb+Ta) | 3.15 | 4.15 |

| Iron (Fe) | — | 5.0 |

| Aluminum (Al) | — | 0.4 |

| Titanium (Ti) | — | 0.4 |

| Carbon (C) | — | 0.10 |

| Manganese (Mn) | — | 0.50 |

| Silicon (Si) | — | 0.50 |

| Phosphorus (P) | — | 0.015 |

| Sulfur (S) | — | 0.015 |

Note: Nickel content typically exceeds 58% by weight.

Mechanical Properties (Annealed Condition)

| Property | Typical Value |

|---|---|

| Tensile Strength (Rm) | ≥ 760 MPa (110 ksi) |

| Yield Strength (Rp0.2) | ≥ 345 MPa (50 ksi) |

| Elongation at Break (A5) | ≥ 30% |

| Hardness (HBW) | ≤ 220 |

| Density | 8.44 g/cm³ |

| Melting Range | 1290–1350°C (2350–2460°F) |

Values conform to ASTM B443 / ASME SB-443 specifications for annealed plate/sheet.

Physical Properties

| Property | Value |

|---|---|

| Coefficient of Thermal Expansion (20–100°C) | 12.9 × 10⁻⁶ /°C |

| Thermal Conductivity (100°C) | ~9.8 W/m·K |

| Specific Heat Capacity (20–100°C) | 410 J/kg·K |

| Electrical Resistivity (20°C) | 1.29 µΩ·m |

| Modulus of Elasticity (20°C) | 205 GPa |

These balanced physical characteristics contribute significantly to Inconel 625’s excellent thermal shock resistance, making it suitable for components subjected to rapid heating and cooling cycles.

Why Choose Inconel 625 Plate & Sheet?

1. Unrivaled Corrosion Performance

Inconel 625 resists pitting, crevice corrosion, and stress corrosion cracking—even in seawater, brine, and acidic chlorides. It outperforms stainless steels and many other nickel alloys in harsh chemical environments.

2. Reliability in Extreme Temperatures

From cryogenic (-196°C) to red-hot (980°C) conditions, Inconel 625 maintains ductility, toughness, and load-bearing capacity. This makes it indispensable in jet engines, exhaust systems, and furnace hardware.

3. Welding Without Compromise

Unlike some high-strength alloys that require post-weld heat treatment, Inconel 625 can be welded using conventional techniques (GTAW, GMAW, SMAW) without preheating or post-weld annealing—saving time and cost while preserving integrity.

4. Long Service Life = Lower TCO

Although initial material cost is higher than standard alloys, Inconel 625’s durability drastically reduces maintenance, downtime, and replacement frequency—delivering superior total cost of ownership (TCO) in critical systems.

Common Applications

| Industry | Application Examples |

|---|---|

| Aerospace | Jet engine combustors, turbine blades, afterburner components, thrust reversers |

| Marine | Subsea pipelines, risers, seawater valves, offshore platform components |

| Chemical Processing | Reactors, distillation columns, heat exchangers, acid-handling equipment |

| Oil & Gas | Downhole instrumentation, sour gas service piping, flare stacks |

| Power Generation | Nuclear reactor cores, steam generator tubes, flue gas desulfurization (FGD) systems |

| Pollution Control | Scrubbers, absorbers, ducting in waste incineration plants |

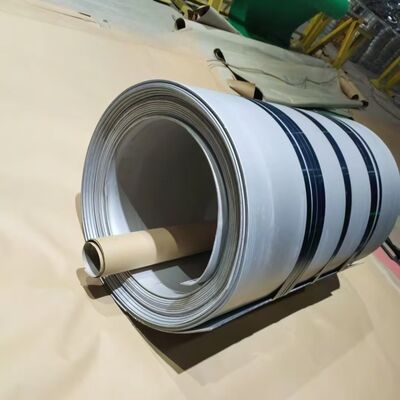

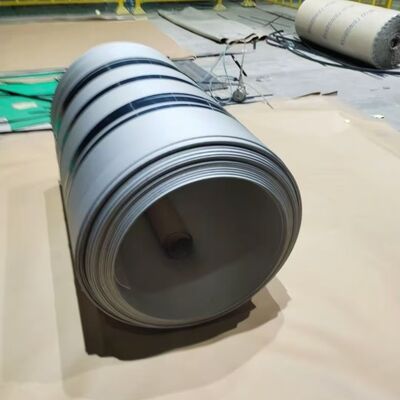

Available Forms & Dimensions

We supply Inconel 625 in a comprehensive range of flat-rolled products:

- Plate: Thickness from 4.0 mm to 150 mm

- Sheet: Thickness from 0.5 mm to 6.0 mm

- Widths: Up to 2500 mm (standard); custom widths available

- Lengths: Up to 12,000 mm

- Surface Finishes: Hot-rolled (as-rolled), cold-rolled, pickled, polished (2B, BA, No.4)

- Certifications: Mill Test Reports (MTRs) per EN 10204 3.1/3.2, full traceability

All products undergo rigorous quality control, including ultrasonic testing (UT) for plate thickness >10 mm upon request.

Processing & Fabrication Guidelines

- Cutting: Plasma, laser, waterjet, or abrasive sawing recommended. Avoid excessive heat buildup.

- Forming: Excellent cold-forming capability; warm forming (300–650°C) may be used for severe bends.

- Machining: Use rigid setups, low cutting speeds, and high feed rates. Carbide tools preferred.

- Welding: No preheat required. Use matching filler metal (e.g., ERNiCrMo-3). Post-weld cleaning restores full corrosion resistance.

Tip: Avoid prolonged exposure in the 600–850°C range to prevent embrittlement due to gamma-double-prime (γ'') phase precipitation.

Compliance & Standards

Our Inconel 625 plate and sheet comply with:

- ASTM B443: Standard specification for nickel-chromium-molybdenum-columbium alloy plate, sheet, and strip

- ASME SB-443: Boiler and pressure vessel code version

- AMS 5599: Aerospace Material Specification for sheet and strip

- NACE MR0175/ISO 15156: Qualified for H₂S-containing (“sour”) oil & gas environments

- PED 2014/68/EU: Pressure Equipment Directive compliant

- RoHS & REACH: Fully compliant with EU environmental regulations

Frequently Asked Questions (FAQ)

Q: Is Inconel 625 magnetic?

A: No—it is essentially non-magnetic in the annealed condition, making it suitable for sensitive electronic or MRI environments.

Q: Can it be used in seawater applications?

A: Absolutely. Inconel 625 is one of the most seawater-resistant alloys available, widely used in naval and offshore systems.

Q: How does it compare to Hastelloy C-276?

A: Both offer excellent corrosion resistance, but Inconel 625 has higher strength and better fabricability, while C-276 excels in reducing acids like HCl. Selection depends on specific media and temperature.

Q: What is the maximum continuous service temperature?

A: Up to 980°C (1800°F) in oxidizing atmospheres. For long-term exposure above 700°C, consider potential age-hardening effects.

Conclusion

When your application demands uncompromising performance under extreme heat, pressure, or corrosion, premium Inconel 625 nickel alloy plate and sheet deliver the ultimate combination of strength, stability, and longevity. Backed by global standards, proven in mission-critical systems worldwide, and engineered for tomorrow’s toughest challenges, Inconel 625 isn’t just a material—it’s your assurance of operational excellence.

Contact us today for technical datasheets, stock availability, custom dimensions, or expert metallurgical support. Let’s build resilience into your next project—together.

More Trade Mark: Inconel 625 plate, Inconel 625 sheet, nickel alloy plate, high-temperature corrosion resistant alloy, UNS N06625, ASTM B443, marine grade nickel alloy, aerospace nickel sheet, chemical processing alloy, heat-resistant plate, Inconel 625 supplier, corrosion-resistant metal sheet, high-strength nickel alloy, thermal shock resistant alloy, NACE compliant nickel alloy.

![]()

![]()

![]()

![]()