-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

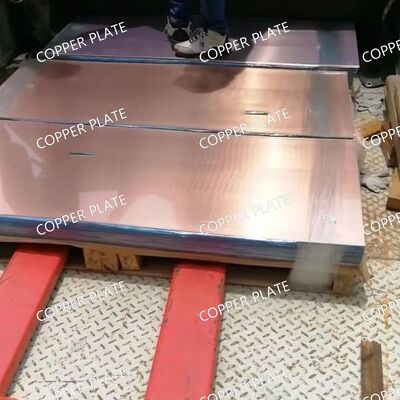

Durable CU-ETP Electrolytic Tough-Pitch Copper Plate for Fabrication and Engineering

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products | Copper Plate Sheet | Material | Copper Flat Bar |

|---|---|---|---|

| Thickness | 0.5 - 40mm | Shape | Flat , Round, Square, Hexagonal.etc |

| Width | 10 - 1250mm | Service | Cutting |

| Other Products | Sheet, Plate, Coil,strip,bar,pipe | Packing | Carton Box, Wooden Box |

| Highlight | CU-ETP copper plate for fabrication,electrolytic tough-pitch copper sheet,durable copper plate for engineering |

||

Durable CU-ETP Electrolytic Tough-Pitch Copper Plate for Fabrication and Engineering

Products Specification

|

Material

|

Copper Plate | |

|

Grade

|

ASTM

|

C10100,C11000,C12200,C21000,C22000,C23000,C24000,C26000,

C27000,C26800,C27200,C27400,C28000,C36500,C33000,C35300, C35600,C36000,C38500,C44300,C46400,C52100,C54400,C62300, C65500,C67500,C67600,C86300,C90700,C93200,C95400 etc. |

|

G/B

|

TU1,T2,TP2,H96,H90,H85,H80,H70,H65,H63,H62,H59,HPb63-3,

HPb66-0.5,HPb62-2,HPb62-3,HPb59-3,HSn70-1,HSn62-1,QSn8-0.3, QSn4-4-4,QAl9-4,QSB-1 etc. |

|

|

JIS

|

C 1011,C 1100,C 1220,C3604,C 2100,C 2200,C 2300,C 2400, C 2600,

C 2700,C 2680,C 2720,C 2800,C 4430,C 4640,C 5210, C 5441, CAC304 etc |

|

|

BS

|

Cu-OFE,C 101,Cu-DHP,CZ 125,CZ 101,CZ 102,CZ 103,CZ 106,CZ 107, CZ 108,CZ 109,CZ 123,CZ 124,CZ 121,CZ 111,CZ 133, Pb 104,

CS 101, CuSn10P etc. |

|

|

DIN/ISO

|

CuZn5,CuZn10,CuZn15,CuZn20,CuZn30,CuZn35,CuZn33,CuZn36,

CuZn37,CuZn40,CuZn40Pb,CuZn37Pb2,CuZn36Pb3,CuZn39Pb3, CuZn28Sn1,CuZn38Sn1,CuSn8,CuSn4Pb4Zn3,CuSi3Mn,CuZn25Al5, CuSn10, CuSn7Zn3Pb7 etc. |

|

|

Shape

|

Round, Square, Flat, Hexagon, Oval, Half-round or Customized

|

|

|

Dimension

|

Bar/Rod

|

Standard(Diameter 5-160 mm) or Customized

|

|

Wire

|

Standard(Diameter 0.02-6 mm) or Customized

|

|

|

Plate/Sheet

|

Standard(T 0.2-50 mm/W 200-3000 mm/L 6000 mm) or Customized

|

|

|

Strip

|

Standard(T 0.05-1.5 mm/W 20-600 mm/L 20000 mm) or Customized

|

|

|

Tube/Pipe

|

Standard(OD 3-360mm/Wall thickness 0.5-50 mm) or Customized

|

|

|

Standard

|

GB/T,JIS,ASTM, ISO, DIN, BS, NF etc.

|

|

|

Hardness

|

1/16 hard,1/8 hard,3/8 hard,1/4 hard,1/2hard,full hard.

|

|

|

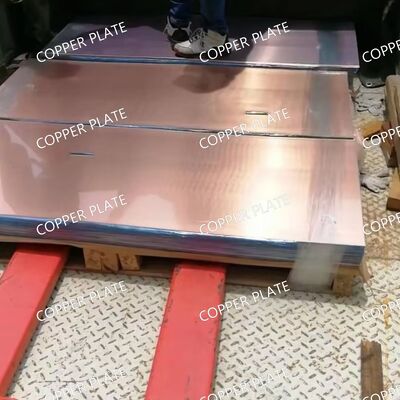

Package

|

Plastic film + Wooden case or as per customer requirement

|

|

|

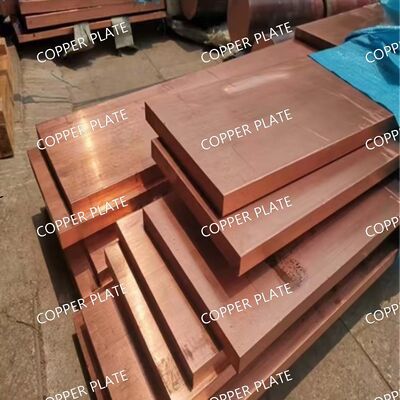

Surface

|

Polished,bright,oiled,hair line,brush,mirror,or as required

|

|

|

Deliver time

|

According to order's quantity.

|

|

|

Shipment

|

By sea, by air, DHL, UPS, FedEx etc. or as required

|

|

|

Application

|

Electric light industry, machinery manufacturing, Building industry ,defense industry, and other fields Manufacturing industrial

|

|

Overview

The CU-ETP (Electrolytic Tough-Pitch) copper plate, designated as UNS C11000, is a cornerstone material in modern fabrication and engineering due to its exceptional balance of electrical conductivity, thermal performance, mechanical workability, and long-term durability. Unlike alloyed coppers, CU-ETP maintains near-pure copper composition—typically 99.9% Cu—with a controlled oxygen content that enhances hot-working characteristics without compromising core functional properties.

Engineers, fabricators, and industrial designers rely on CU-ETP plates for applications demanding precision, reliability, and resilience—from heavy-duty electrical infrastructure to custom-engineered heat management systems. This product information page delivers a technically accurate, SEO-optimized overview tailored for procurement professionals, design engineers, and metal specifiers seeking high-performance copper solutions.

Understanding CU-ETP (C11000) Copper

CU-ETP stands for Electrolytic Tough-Pitch copper, produced via electrolytic refining of blister copper. The “tough pitch” refers to the deliberate addition of 200–400 ppm oxygen, which improves cast integrity and hot ductility during rolling or extrusion. While this oxygen content precludes use in hydrogen-rich or high-vacuum environments (due to risk of steam embrittlement), it is perfectly suited for atmospheric, aqueous, and standard industrial conditions.

CU-ETP aligns with multiple international standards:

- UNS C11000 (United States)

- CW004A (Europe, per EN 13601)

- C1100 / T2 (China, per GB/T 2040)

- C1101 / C1100 (Japan, per JIS H3100)

This global recognition ensures seamless integration into international supply chains and compliance with regional engineering codes.

Why CU-ETP Excels in Fabrication & Engineering

Unlike high-strength copper alloys (e.g., beryllium copper or phosphor bronze), CU-ETP prioritizes functional performance over mechanical hardness—making it ideal where conductivity, corrosion resistance, and formability are paramount. Key advantages include:

- Superior Electrical Conductivity: ≥100% IACS—critical for power transmission components.

- Excellent Thermal Diffusivity: Efficient heat transfer in thermal management systems.

- High Ductility: Can be cold-formed into complex geometries without cracking.

- Weldability & Joinability: Compatible with soldering, brazing, and resistance welding.

- Natural Corrosion Resistance: Performs reliably in humid, marine, and mildly acidic environments.

- Long Service Life: Minimal degradation over decades when properly installed.

These traits make CU-ETP not just a material—but a performance enabler in demanding engineering contexts.

Technical Data: CU-ETP Copper Plate Specifications

The table below outlines key physical, mechanical, and chemical properties of standard annealed (O-temper) CU-ETP plates:

| Parameter | Value / Specification |

|---|---|

| UNS Designation | C11000 |

| Common Names | ETP Copper, Pure Copper, Oxygen-Bearing Copper, T2 (China) |

| Chemical Composition | Cu + Ag ≥ 99.90%; O: 0.02–0.04%; Pb ≤ 0.005%; Fe ≤ 0.005%; S ≤ 0.005% |

| Electrical Conductivity | ≥100% IACS at 20°C |

| Thermal Conductivity | ~398 W/(m·K) |

| Density | 8.94 g/cm³ |

| Melting Range | 1083–1085°C |

| Coefficient of Thermal Expansion | 16.5 × 10⁻⁶ /°C (20–100°C) |

| Modulus of Elasticity | 110–128 GPa |

| Tensile Strength (Annealed) | 200–250 MPa |

| Yield Strength (0.2% offset) | 60–80 MPa |

| Elongation | ≥45% (in 50 mm) |

| Hardness (HV) | 40–50 (annealed); up to 110 HV (full hard temper) |

| Available Tempers | Annealed (O), 1/4 Hard (H01), 1/2 Hard (H02), Full Hard (H04) |

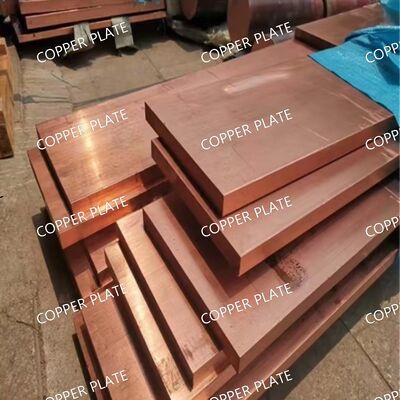

| Thickness Range | 0.2 mm to 150 mm |

| Width & Length | Up to 2500 mm wide; lengths customized (standard: 1000–6000 mm) |

| Surface Options | Mill finish, bright annealed, brushed, pickled, oiled, or custom polished |

| Standards Compliance | ASTM B152, EN 13601, GB/T 2040, JIS H3100, ISO 1337 |

✅ All plates can be supplied with mill test reports (MTRs), RoHS/REACH compliance certificates, and dimensional inspection records upon request.

Engineering Applications Across Industries

CU-ETP copper plates are not limited to electrical uses—they serve as critical structural and functional elements in diverse engineering fields:

| Sector | Typical Applications |

|---|---|

| Power Engineering | Busbars, grounding grids, transformer laminations, switchgear panels |

| Industrial Fabrication | Custom jigs, electrode blanks, EDM electrodes, stamping dies |

| Renewable Energy | Solar thermal absorber plates, battery interconnects in BESS, wind turbine grounding |

| Transportation | EV battery busbars, rail electrification components, marine bonding systems |

| Process Equipment | Liners for chemical tanks (non-oxidizing acids), distillation columns, reactor parts |

| Thermal Systems | Heat spreaders, cooling plates, refrigeration manifolds, cryogenic shielding |

| Defense & Aerospace | RF shielding enclosures, waveguide components, non-sparking tooling |

| Custom Manufacturing | Prototype parts, artistic metalwork, precision machining blanks |

Notably, CU-ETP’s low contact resistance and stable oxide layer make it ideal for high-reliability electrical joints—a key consideration in safety-critical systems.

Fabrication Guidelines for CU-ETP Plates

To maximize performance and avoid defects, follow these best practices:

Cutting & Machining

- Use sharp, high-speed steel or carbide tools.

- Apply generous coolant to prevent work hardening.

- Recommended cutting speed: 150–300 m/min (depending on temper).

Forming & Bending

- Minimum bend radius: 0.5× thickness (annealed); 1.5× (full hard).

- Annealing may be required after severe cold working (>30% deformation).

Joining

- Soldering: Use rosin-core or mildly activated fluxes.

- Brazing: Phosphorus-copper or silver-based alloys recommended.

- Welding: TIG preferred; avoid oxy-acetylene in confined spaces (risk of porosity).

Surface Treatment

- Clean with citric or acetic acid to remove oxides.

- Apply clear acrylic lacquer to preserve bright finish indoors.

- For outdoor use, allow natural patina formation or apply protective coatings.

⚠️ Avoid hydrogen exposure above 200°C—oxygen in ETP copper can react to form steam, causing internal cracks.

Comparison: CU-ETP vs. Alternative Copper Grades

| Material | Conductivity (%IACS) | Oxygen Content | Key Use Case | Limitation |

|---|---|---|---|---|

| CU-ETP (C11000) | ≥100% | 0.02–0.04% | General electrical, thermal, fabrication | Not for vacuum/hydrogen service |

| OFC (C10200) | ≥101% | <0.001% | Vacuum tubes, semiconductor, aerospace | Higher cost, lower hot strength |

| C12200 (DHP) | 85–90% | 0.015–0.04% P | Plumbing, HVAC tubing | Lower conductivity |

| C18150 (Cr-Zr) | 80% | Alloyed | High-strength electrodes, spot welding | Reduced conductivity |

For 90% of industrial and electrical applications, CU-ETP offers the optimal blend of performance, availability, and cost-effectiveness.

Quality Control & Traceability

Reputable manufacturers implement rigorous quality protocols:

- Spectrometric analysis for elemental verification

- Ultrasonic testing for internal homogeneity (optional)

- Dimensional tolerance checks per ASTM/EN flatness standards

- Batch traceability from cathode lot to final shipment

All plates are typically free of seams, blisters, and laminations, with surface defects limited to acceptable mill marks unless specified otherwise.

Ordering & Customization Options

When sourcing CU-ETP plates, specify the following to ensure fit-for-purpose delivery:

- Grade: UNS C11000 / CW004A / T2

- Temper: Annealed (most common), 1/2 Hard, etc.

- Dimensions: Thickness × Width × Length (tolerances: ±0.05 mm typical for thin gauges)

- Finish: e.g., “Bright annealed both sides” or “Mill finish, oiled”

- Certification Needs: MTR, RoHS, third-party inspection

- Packaging: Standard export pallets or VCI-wrapped for long-term storage

Lead Times:

- Stock sizes: 3–7 business days

- Custom orders: 2–4 weeks

MOQ: Flexible—from sample pieces (1 kg) to container-load quantities.

Sustainability & Lifecycle Value

CU-ETP copper is among the most sustainable industrial metals:

- Recycled content: Often >40% in new production

- Infinite recyclability: No loss of properties after recycling

- Energy recovery: Scrap retains ~90% of primary metal value

- Low environmental impact: Naturally occurring, non-toxic, and biostatic

Its 50+ year service life in many applications reduces replacement frequency and lifecycle costs—aligning with ESG and circular economy goals.

Frequently Asked Questions

Q: Can CU-ETP be used outdoors?

Yes. It forms a stable green patina (basic copper carbonate) that protects against further corrosion—common in roofing and architectural cladding.

Q: Is it suitable for food-contact applications?

Yes, provided surfaces are properly cleaned and maintained. Copper is approved under FDA and EU regulations for indirect food contact.

Q: How does temperature affect performance?

Conductivity decreases slightly with rising temperature (~0.4% per °C), but mechanical stability remains excellent up to 200°C.

Q: Can it be anodized like aluminum?

No—copper does not form a hard anodic layer. Instead, use chemical passivation or coatings for color/stability control.

Q: What’s the difference between “plate” and “sheet”?

Generally, sheet = <6 mm thick; plate = ≥6 mm. Both are available in CU-ETP.

Final Thoughts

The Durable CU-ETP Electrolytic Tough-Pitch Copper Plate is far more than a commodity metal—it is a high-performance engineering material trusted across continents for mission-critical applications. Its unique combination of purity, conductivity, and fabricability ensures it remains indispensable in an electrified, energy-conscious world.

Whether you’re designing a next-generation power converter, fabricating custom industrial tooling, or engineering a sustainable building system, CU-ETP delivers proven reliability, global standardization, and long-term value.

Contact us today for technical datasheets, sample requests, or volume quotations. We support global shipping with full documentation and metallurgical expertise.

CU-ETP Copper Plate, C11000 Copper Sheet, Electrolytic Tough Pitch Copper, Durable Copper Plate for Engineering, Fabrication-Grade Copper, T2 Copper Plate, High-Conductivity Copper Plate, Industrial Copper Sheet C11000, Copper Plate for Busbars, ASTM B152 Copper Plate.

![]()

![]()

![]()

![]()