-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

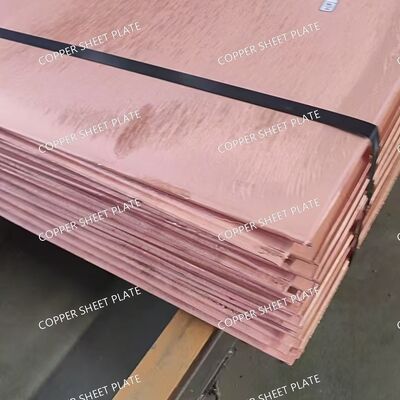

High Purity C11000 Electrolytic Tough Pitch (ETP) Copper Plate Excellent Electrical Conductivity and Formability

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products | Copper Plate Sheet | Material | Copper Flat Bar |

|---|---|---|---|

| Thickness | 3 - 40mm | Shape | Flat , Round, Square, Hexagonal.etc |

| Width | 10 - 1250mm | Service | Cutting |

| Other Products | Sheet, Plate, Coil,strip,bar,pipe | Packing | Carton Box, Wooden Box |

| Highlight | High purity C11000 copper plate,ETP copper sheet excellent conductivity,Copper plate high formability |

||

High Purity C11000 Electrolytic Tough Pitch (ETP) Copper Plate Excellent Electrical Conductivity and Formability

Products Specification

|

Material

|

Copper and Copper alloy products | |

|

Grade

|

ASTM

|

C10100,C11000,C12200,C21000,C22000,C23000,C24000,C26000,

C27000,C26800,C27200,C27400,C28000,C36500,C33000,C35300, C35600,C36000,C38500,C44300,C46400,C52100,C54400,C62300, C65500,C67500,C67600,C86300,C90700,C93200,C95400 etc. |

|

G/B

|

TU1,T2,TP2,H96,H90,H85,H80,H70,H65,H63,H62,H59,HPb63-3,

HPb66-0.5,HPb62-2,HPb62-3,HPb59-3,HSn70-1,HSn62-1,QSn8-0.3, QSn4-4-4,QAl9-4,QSB-1 etc. |

|

|

JIS

|

C 1011,C 1100,C 1220,C3604,C 2100,C 2200,C 2300,C 2400, C 2600,

C 2700,C 2680,C 2720,C 2800,C 4430,C 4640,C 5210, C 5441, CAC304 etc |

|

|

BS

|

Cu-OFE,C 101,Cu-DHP,CZ 125,CZ 101,CZ 102,CZ 103,CZ 106,CZ 107, CZ 108,CZ 109,CZ 123,CZ 124,CZ 121,CZ 111,CZ 133, Pb 104,

CS 101, CuSn10P etc. |

|

|

DIN/ISO

|

CuZn5,CuZn10,CuZn15,CuZn20,CuZn30,CuZn35,CuZn33,CuZn36,

CuZn37,CuZn40,CuZn40Pb,CuZn37Pb2,CuZn36Pb3,CuZn39Pb3, CuZn28Sn1,CuZn38Sn1,CuSn8,CuSn4Pb4Zn3,CuSi3Mn,CuZn25Al5, CuSn10, CuSn7Zn3Pb7 etc. |

|

|

Shape

|

Round, Square, Flat, Hexagon, Oval, Half-round or Customized

|

|

|

Dimension

|

Bar/Rod

|

Standard(Diameter 5-160 mm) or Customized

|

|

Wire

|

Standard(Diameter 0.02-6 mm) or Customized

|

|

|

Plate/Sheet

|

Standard(T 0.2-50 mm/W 200-3000 mm/L 6000 mm) or Customized

|

|

|

Strip

|

Standard(T 0.05-1.5 mm/W 20-600 mm/L 20000 mm) or Customized

|

|

|

Tube/Pipe

|

Standard(OD 3-360mm/Wall thickness 0.5-50 mm) or Customized

|

|

|

Standard

|

GB/T,JIS,ASTM, ISO, DIN, BS, NF etc.

|

|

|

Hardness

|

1/16 hard,1/8 hard,3/8 hard,1/4 hard,1/2hard,full hard.

|

|

|

Package

|

Plastic film + Wooden case or as per customer requirement

|

|

|

Surface

|

Polished,bright,oiled,hair line,brush,mirror,or as required

|

|

|

Deliver time

|

According to order's quantity.

|

|

|

Shipment

|

By sea, by air, DHL, UPS, FedEx etc. or as required

|

|

|

Application

|

Electric light industry, machinery manufacturing, Building industry ,defense industry, and other fields Manufacturing industrial

|

|

High Purity C11000 Electrolytic Tough Pitch (ETP) Copper Plate – Excellent Electrical Conductivity and Formability

Overview

C11000 Electrolytic Tough Pitch (ETP) Copper is one of the most widely used copper grades in industrial, electrical, and electronic applications due to its exceptional combination of high electrical and thermal conductivity, excellent formability, and good corrosion resistance. Our high-purity C11000 ETP copper plate meets or exceeds ASTM B187/B187M standards and is ideal for demanding applications where performance, reliability, and consistency are paramount.

Manufactured through a controlled electrolytic refining process, this copper plate maintains a minimum purity of 99.90% Cu, with oxygen content carefully balanced to optimize mechanical and electrical properties. Whether you're designing busbars, heat exchangers, electrical connectors, or architectural components, our C11000 copper plate delivers unmatched quality and performance.

Key Features & Benefits

- Exceptional Electrical Conductivity: ≥100% IACS (International Annealed Copper Standard)

- Superior Thermal Conductivity: Ideal for heat transfer applications

- Excellent Formability: Easily bent, stamped, deep-drawn, or rolled without cracking

- Good Solderability & Brazability: Facilitates reliable joining processes

- High Purity: ≥99.90% Cu with tightly controlled impurities

- Consistent Quality: Produced under strict quality control per ASTM, ISO, and RoHS standards

- Corrosion Resistance: Performs well in atmospheric and mildly aggressive environments

Typical Applications

| Industry | Application Examples |

|---|---|

| Electrical & Electronics | Busbars, switchgear components, transformer windings, printed circuit board (PCB) substrates, grounding systems |

| Renewable Energy | Solar panel frames, photovoltaic cell interconnects, battery current collectors |

| Automotive | EV battery components, wiring harnesses, motor windings |

| Industrial Manufacturing | Heat exchangers, condenser plates, welding electrodes |

| Construction & Architecture | Roofing, cladding, decorative panels, antimicrobial surfaces |

| Telecommunications | RF shielding, coaxial cable conductors, base station components |

Chemical Composition (ASTM B187 Compliant)

| Element | Content (%) | Max Limit |

|---|---|---|

| Copper (Cu) + Silver (Ag) | ≥ 99.90 | — |

| Oxygen (O) | 0.02–0.04 | Controlled |

| Lead (Pb) | ≤ 0.005 | 0.005 |

| Iron (Fe) | ≤ 0.005 | 0.005 |

| Nickel (Ni) | ≤ 0.005 | 0.005 |

| Phosphorus (P) | ≤ 0.005 | 0.005 |

| Sulfur (S) | ≤ 0.005 | 0.005 |

| Other Impurities (each) | ≤ 0.001 | 0.001 |

| Total Impurities | ≤ 0.10 | 0.10 |

Note: Composition may be adjusted slightly based on customer-specific requirements and end-use conditions.

Mechanical Properties (Typical Values)

| Condition | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HV) |

|---|---|---|---|---|

| Annealed (O60) | 210–250 | 60–80 | 45–50 | 40–50 |

| Half-Hard (H02) | 280–330 | 240–280 | 10–15 | 80–95 |

| Hard (H04) | 340–390 | 310–350 | 3–8 | 100–120 |

Values may vary slightly depending on thickness, width, and processing parameters.

Physical Properties

| Property | Value |

|---|---|

| Density (20°C) | 8.94 g/cm³ |

| Melting Point | 1083°C |

| Electrical Conductivity | ≥100% IACS (at 20°C) |

| Thermal Conductivity | 398 W/(m·K) |

| Coefficient of Thermal Expansion (20–100°C) | 16.5 × 10⁻⁶ /°C |

| Modulus of Elasticity | 110–128 GPa |

| Specific Heat Capacity | 0.385 J/(g·K) |

Available Dimensions & Tolerances

Our C11000 ETP copper plates are available in a wide range of standard and custom dimensions:

| Parameter | Standard Range |

|---|---|

| Thickness | 0.5 mm to 100 mm |

| Width | Up to 1200 mm |

| Length | Up to 3000 mm (custom lengths available) |

| Surface Finish | Mill finish, polished, brushed, or coated upon request |

| Edge Type | Slit edge, sheared edge, or deburred |

Tolerances comply with ASTM B209 or as per customer specification (e.g., ±0.05 mm for thickness in precision applications).

Why Choose High-Purity C11000 ETP Copper?

- Unmatched Conductivity: With ≥100% IACS, it sets the benchmark for electrical efficiency—critical in power transmission and high-frequency electronics.

- Reliable Performance: Consistent oxygen content ensures stable mechanical properties and prevents hydrogen embrittlement in reducing atmospheres.

- Eco-Friendly & Recyclable: Copper is 100% recyclable without loss of properties, supporting sustainable manufacturing.

- Global Compliance: Meets international standards including ASTM B187, UNS C11000, EN CW004A, and DIN 2.0090.

- Traceability & Certification: Full material test reports (MTRs), RoHS/REACH compliance documentation, and batch traceability provided.

Processing & Fabrication Guidelines

C11000 ETP copper plate is highly workable using standard metalworking techniques:

- Cutting: Shearing, laser cutting, waterjet, or plasma (with appropriate settings to avoid oxidation).

- Forming: Excellent cold-forming capabilities; annealing recommended for severe deformation.

- Machining: Moderate machinability; use sharp tools and lubricants to reduce galling.

- Joining: Readily soldered, brazed, or welded (TIG/MIG with inert gas shielding recommended).

- Surface Treatment: Can be passivated, tin-plated, nickel-plated, or coated for enhanced corrosion resistance or aesthetics.

Avoid prolonged exposure to sulfur-containing atmospheres to prevent tarnishing.

Quality Assurance

Every batch of our C11000 copper plate undergoes rigorous testing, including:

- Spectrometric analysis for chemical composition

- Eddy current or four-point probe testing for electrical conductivity

- Tensile and hardness testing per ASTM E8/E18

- Ultrasonic inspection for internal defects (optional for critical applications)

- Dimensional verification with calibrated metrology tools

We maintain ISO 9001:2015 certification and offer full documentation for aerospace, medical, and energy sector clients.

Packaging & Delivery

To ensure product integrity during transit:

- Plates are wrapped in anti-tarnish paper and VCI film

- Palletized with wooden spacers and corner protectors

- Export-standard fumigated wooden crates available

- Just-in-time (JIT) delivery and inventory management services offered

Frequently Asked Questions (FAQ)

Q: Is C11000 suitable for vacuum or high-temperature applications?

A: Due to its oxygen content (~0.03%), C11000 may suffer from hydrogen embrittlement above 200°C in reducing atmospheres. For such environments, oxygen-free copper (e.g., C10100/C10200) is recommended.

Q: What’s the difference between C11000 and C10200?

A: C11000 contains controlled oxygen for improved hot workability and conductivity, while C10200 is oxygen-free (<0.001% O), making it better for welding and high-temperature service.

Q: Can you provide certified conductivity test reports?

A: Yes. We provide third-party verified conductivity reports (≥100% IACS) with every shipment upon request.

Q: Do you offer custom temper or surface finishes?

A: Absolutely. We can supply plates in annealed, half-hard, hard, or spring tempers, along with mirror-polished, brushed, or anti-reflective finishes.

Conclusion

For engineers, designers, and procurement professionals seeking a reliable, high-performance copper solution, high-purity C11000 Electrolytic Tough Pitch Copper Plate stands out as the gold standard. Its optimal balance of conductivity, formability, and cost-effectiveness makes it indispensable across modern industries—from next-generation electric vehicles to renewable energy infrastructure and advanced electronics.

Partner with us to access premium-grade C11000 copper plates backed by technical expertise, global logistics, and unwavering quality commitment.

Contact Us Today for samples, technical data sheets, or a customized quotation.

![]()

![]()

![]()

![]()