All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

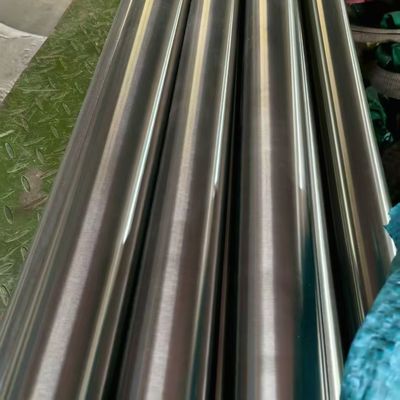

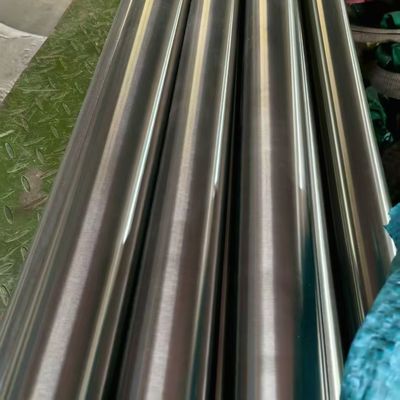

Hastelloy C276 Bright Bar High Corrosion Resistance Polished Surface for Chemical Processing and Marine Applications

Product Details

| Products | Hastelloy C276 Bright Bar | Grade | Hastelloy C276 |

|---|---|---|---|

| Diameter | 5 - 350mm | Length | Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | Bright |

| Highlight | Hastelloy C276 bright bar,corrosion resistant nickel alloy bar,polished Hastelloy bar for marine |

||

Product Description

Hastelloy C276 Bright Bar High Corrosion Resistance Polished Surface for Chemical Processing and Marine Applications

More Specification Informations

| Products Name | Hastelloy C276 Bright Bar |

| Diameter | 5 - 350mm |

| Length | custom cutting any length as request |

| Surface | bright, Black |

| Brand | DELTA |

| Service | cutting, Polishing |

| MOQ | 2 Kgs |

| Other Type | bar, strip,coil,pipe.sheet, plate,wire.etc |

| Packing | Wooden box |

| Loading Port | Shanghai Port |

| Price term | EXW,FOB,CIF,CFR |

| Deliver time | within 12 days |

Hastelloy C276 Bright Bar - High Corrosion Resistance, Polished Surface for Chemical Processing & Marine Applications

In industrial environments where corrosion, high temperatures, and mechanical stress converge, material performance directly determines operational safety and efficiency. Hastelloy C276 Bright Bar (UNS N10276 / W.Nr. 2.4819) emerges as a premium solution, combining unparalleled corrosion resistance with a precision-polished surface to meet the stringent demands of chemical processing and marine industries. This nickel-chromium-molybdenum-tungsten alloy redefines durability in harsh conditions, making it a staple for critical infrastructure worldwide.

Core Composition: The Foundation of Superior Performance

At its core, Hastelloy C276 Bright Bar owes its strength to a meticulously balanced chemical profile. Nickel forms the alloy’s base, providing inherent resistance to stress corrosion cracking (SCC) and serving as a matrix for enhancing other elements. Chromium (14.5–16.5%) creates a protective oxide layer that shields against oxidation and general corrosion, while molybdenum (15.0–17.0%) delivers exceptional resistance to reductive acids and chloride-induced pitting—a common failure point for conventional stainless steels. Tungsten (3.0–4.5%) further amplifies resistance to localized attack, particularly in chloride-rich environments, and silicon/carbon contents are strictly limited (≤0.08% and ≤0.01% max, respectively) to prevent intergranular corrosion, especially after welding. This composition results in a material with a density of 8.89–8.9 g/cm³ and a melting range of 1325–1370°C, balancing structural integrity with thermal stability.

Unmatched Corrosion Resistance: Defying Harsh Media

Hastelloy C276 Bright Bar’s most defining attribute is its universal corrosion resistance, outperforming most alloys in both oxidizing and reducing environments. It withstands a broad spectrum of aggressive media, including hydrochloric acid, sulfuric acid, phosphoric acid, formic acid, and acetic acid—critical for chemical processing where multiple corrosive agents may coexist. Unlike austenitic stainless steels, it resists chloride-induced pitting and crevice corrosion, even in high-salinity solutions like seawater or brines used in desalination plants.

Notably, it excels in environments contaminated with chlorine, ammonia, or heavy metals (e.g., iron/copper ammonides) and remains stable in moist chlorine gas, hypochlorite, and chlorine dioxide solutions—applications where many materials degrade rapidly. Welding, a common stressor for corrosion-resistant alloys, rarely compromises its performance: the alloy avoids grain boundary precipitates in the heat-affected zone, maintaining corrosion resistance in welded assemblies without post-weld heat treatment. This makes it ideal for fabricating complex components like valves, pumps, or pipe fittings where welding is unavoidable.

Polished Surface: Beyond Aesthetics to Functional Value

The "bright bar" designation refers to its precision-polished surface finish, achieved through cold drawing and mechanical polishing processes. Unlike hot-rolled (HR) or matte cold-rolled (CR) bars, the polished surface (often comparable to BA No. 8 finish) serves three critical functions. First, it minimizes crevice formation—microscopic grooves in unpolished surfaces trap corrosive media, accelerating pitting. A smooth surface eliminates these traps, extending service life in chloride-rich or acidic environments.

Second, it enhances cleanliness, a priority for pharmaceutical, food processing, and specialty chemical applications where product contamination from material degradation must be avoided. The polished surface is easier to sanitize and resists residue buildup, ensuring compliance with strict industry regulations. Finally, it improves fluid dynamics in applications like pump shafts or mixer rods, reducing turbulence-induced erosion-corrosion—a common issue in high-flow chemical reactors or marine propulsions systems.

Mechanical Properties: Strength Under Pressure

Beyond corrosion resistance, Hastelloy C276 Bright Bar delivers robust mechanical performance. In the solution-annealed condition (the standard for most applications), it achieves a minimum yield strength of 283 MPa, tensile strength of 690 MPa, and elongation of 40%—with typical values exceeding these benchmarks (402 MPa yield, 794 MPa tensile, 60% elongation) for enhanced ductility and impact resistance. It maintains these properties at elevated temperatures up to 1038°C (1900°F), resisting oxidation and carburization in high-heat processes like furnace operations or thermal fluid systems in chemical plants.

Its low thermal expansion coefficient further ensures dimensional stability during rapid temperature fluctuations, a critical feature for components like heat exchanger tubes or turbine parts that cycle between hot and cold media. Hardness can be tailored (1/4 hard to full hard) based on application needs, though the annealed state (≈195 HB) is most common for balance of strength and fabricability.

Key Applications: Chemical Processing & Marine Industries

Chemical Processing

In chemical and petrochemical plants, Hastelloy C276 Bright Bar is ubiquitous in equipment handling corrosive feedstocks and byproducts. It fabricates reactor internals, catalyst supports, and valve stems for processes involving chlorinated solvents, methylene diphenyl isocyanate (MDI), and technically impure phosphoric acid—applications where impurity-induced corrosion is a constant risk. Pharmaceutical manufacturers rely on it for drug synthesis equipment, as its corrosion resistance prevents metallic leaching into sensitive products. It also serves in pollution control systems, such as scrubbers treating acidic flue gases, and pulp/paper processing where chlorinated bleaching agents are used.

Marine & Offshore

The marine industry benefits immensely from its resistance to seawater corrosion. Offshore oil and gas platforms use it for drill collars, wellhead components, and pipeline fittings, where exposure to saltwater, sour gas (H₂S), and high pressure creates a hostile environment. Seawater desalination plants employ it in membrane housings and pump shafts, as it withstands the concentrated brines and chlorine used in water treatment. Coastal power plants also utilize it for condenser tubes and cooling system components, where seawater acts as a coolant and corrosion accelerator for lesser materials.

Compliance & Availability

Hastelloy C276 Bright Bar adheres to international standards including ASTM B574 (for bars) and ASTM B575 (for nickel alloy products), ensuring consistent quality across suppliers. It is available in various sizes: round bars range from 4 mm to 500 mm in diameter, while hex bars and custom profiles cater to specialized designs. Suppliers typically stock solution-annealed bars for immediate delivery, with custom finishes or hardness levels available for bulk orders.

Conclusion

Hastelloy C276 Bright Bar stands as a benchmark for high-performance alloys in corrosive environments. Its balanced composition delivers universal corrosion resistance, while the polished surface enhances durability and cleanliness. For chemical processors facing aggressive media or marine engineers battling seawater corrosion, it offers a reliable, long-lasting material solution that minimizes downtime and maintenance costs. As industries demand more resilient materials to meet sustainability and safety goals, Hastelloy C276 Bright Bar remains an indispensable choice for critical applications worldwide.

![]()

![]()

![]()

![]()

Recommended Products