All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

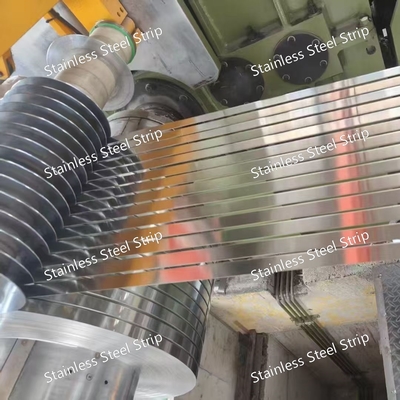

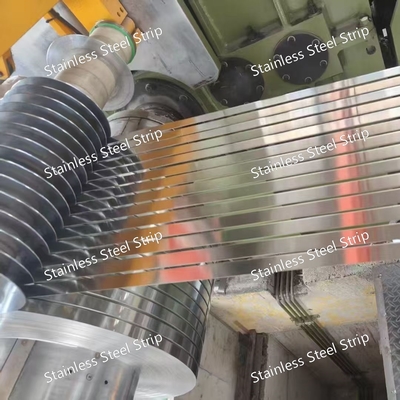

301 Stainless Steel Strip Rolls 0.15-2.0mm Thickness High Hardness

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Products | Stainless Steel Strip | Thickness | 0.15 - 2.0mm |

|---|---|---|---|

| Width | Within 1219mm | MOQ | 500 Kgs |

| Grade | 200 Series 300 Series 300 Series | Surface | BA 2B NO.4 HL 8K NO.1 |

| Standard | ASTM EN GB JIS | Packing | Wooden Frame And Water Proof Paper |

| Highlight | 301 stainless steel strip rolls,high hardness stainless steel strip,0.15-2.0mm stainless steel strip |

||

Product Description

1/4H 1/2H 3/4H FH Stainless Steel Strip Rolls Alloy 301 Spring Steel Strips With High Hardness

Product Attributes

| Attribute | Value |

| Products | 301 stainless steel strip |

| Thickness | 0.15-2.0mm |

| Width | within 1219mm |

| MOQ | 500 kgs |

| Other | 201 301 304 304L 309S 310S 316L 316Ti 410 420 430 436 439 441 444 440A/B/C,2205,2507,904L,C276,400,600,625,926,825.etc |

| Surface | BA 2B NO.4 HL 8K NO.1 |

| Standard | ASTM EN GB JIS |

| Packing | wooden frame and water proof paper |

Introduction

Alloy 301 stainless steel strips, renowned as high-performance spring steel strips, are austenitic stainless steels celebrated for their exceptional work-hardening ability and high hardness across various tempers. Available in 1/4 Hard (1/4H), 1/2 Hard (1/2H), 3/4 Hard (3/4H), and Full Hard (FH) conditions, these strips are engineered to deliver superior strength, elasticity, and corrosion resistance—making them a preferred choice for spring applications and components requiring consistent performance under repeated stress. The cold-rolled tempers enhance their hardness and tensile strength, while the inherent austenitic structure retains good formability, ensuring adaptability to complex bending and forming processes.

Chemical Composition (Typical, % by Weight)

Conforming to industry standards, the chemical composition of Alloy 301 stainless steel is carefully balanced to support its mechanical properties:

- Carbon (C): ≤ 0.15

- Chromium (Cr): 16.0 – 18.0

- Nickel (Ni): 6.0 – 8.0

- Manganese (Mn): ≤ 2.0

- Silicon (Si): ≤ 1.0

- Phosphorus (P): ≤ 0.045

- Sulfur (S): ≤ 0.030

- Nitrogen (N): ≤ 0.10

This composition, rich in chromium and nickel, provides baseline corrosion resistance, while controlled carbon and nitrogen levels contribute to the alloy’s ability to harden during cold working.

Mechanical Properties Across Different Hardness Tempers

The mechanical properties of 301 stainless steel strips vary significantly with cold-worked tempers, directly influencing their hardness, strength, and ductility. Key properties for each temper are as follows:

| Property | 1/4H (1/4 Hard) | 1/2H (1/2 Hard) | 3/4H (3/4 Hard) | FH (Full Hard) |

|---|---|---|---|---|

| Tensile Strength | 700 – 900 MPa | 850 – 1050 MPa | 1000 – 1200 MPa | 1200 – 1450 MPa |

| Yield Strength (0.2% offset) | 450 – 600 MPa | 650 – 800 MPa | 850 – 1050 MPa | 1050 – 1300 MPa |

| Elongation (in 50mm) | 25 – 35% | 15 – 25% | 10 – 15% | 5 – 10% |

| Hardness (Rockwell B/HRC) | 85 – 95 HRB | 95 – 100 HRB / 20 – 25 HRC | 25 – 30 HRC | 30 – 40 HRC |

Note: Values are typical and may vary slightly based on specific manufacturing processes and strip thickness.

Standards

Alloy 301 stainless steel strips comply with major international standards, ensuring consistency and quality:

- Primary Standard: ASTM A666 (Specification for Austenitic Stainless Steel Sheet, Strip, Plate, and Flat Bar)

- Additional Compliance:

- EN 10088-2 (European standard for stainless steel strip/sheet)

- JIS G4305 (Japanese Industrial Standard for cold-rolled stainless steel strips)

- GB/T 3280 (Chinese standard for stainless steel cold-rolled sheets and strips)

Equivalent Grades

301 stainless steel has recognized equivalents in global standards, facilitating cross-industry compatibility:

- UNS: S30100

- EN: 1.4310

- JIS: SUS301

- GB: 12Cr17Ni7 (China)

- DIN: X12CrNi177 (Germany)

Applications

Leveraging their high hardness, elasticity, and corrosion resistance, 301 stainless steel strips (1/4H to FH) are widely used in:

- Spring Components: Tension springs, compression springs, clip springs, and battery contact springs.

- Automotive Industry: Door latches, seat belt components, valve springs, and fuel system clips.

- Electronics: Connector springs, switch contacts, battery terminals, and sensor springs.

- Aerospace: Aircraft cabin hardware, control system springs, and lightweight structural clips.

- Medical Devices: Surgical instrument springs, clamp springs, and diagnostic equipment components.

- Industrial Machinery: Vibration dampers, conveyor belt clips, and machinery tension springs.

Packaging

To protect against corrosion, damage, and contamination during storage and transportation:

- Each coil is wrapped in moisture-proof VCI (Volatile Corrosion Inhibitor) paper to prevent rust.

- Inner layer: Polyethylene film for additional moisture barrier.

- Coils are secured on wooden pallets or steel reels to avoid deformation.

- Outer packaging: Heavy-duty cardboard boxes or steel crates (for bulk shipments).

- Labels include product details (grade, temper, thickness, width, batch number, and standards compliance) for easy identification.

![]()

![]()

![]()

![]()

Recommended Products