All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

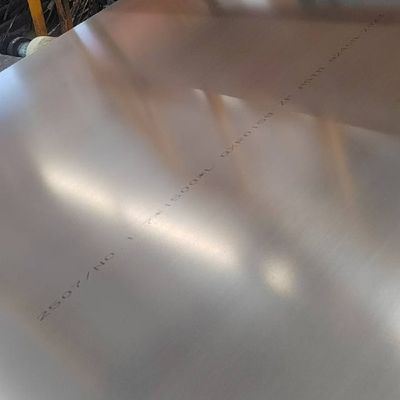

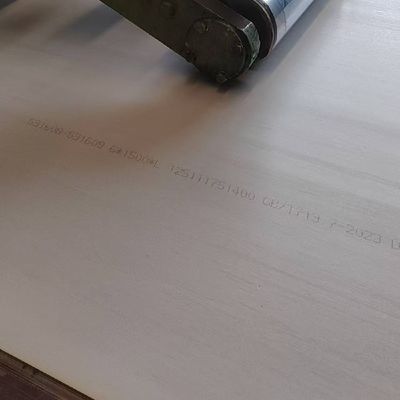

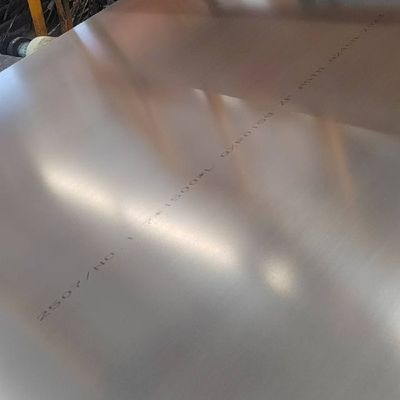

Corrosion Resistant 316H SS Plate For Pressure Vessels Boilers

| Place of Origin | China |

|---|---|

| Brand Name | TISCO BAOSTEEL |

| Certification | ISO |

| Model Number | 316H / S31609 |

| Minimum Order Quantity | 500 kgs |

| Price | 5000 - 7200 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | T/T, Western Union |

| Supply Ability | 20Ton per week |

Product Details

| Products | Stainless Steel Plate | Grade | 316H / S31609 |

|---|---|---|---|

| Thickness | 0.6 - 30.0mm | Width | 1219mm 1500mm 1800mm 2000mm |

| Surface | NO.1 2B | Brand | BAOSTEEL TISCO |

| Standard | ASTM A240/240M | Loading Port | Shanghai Port |

| Highlight | Boilers 316H SS Plate,Pressure Vessels 316H SS Plate,Corrosion Resistant 316H SS Plate |

||

Product Description

Corrosion Resistant 316H SS Plate for Pressure Vessels and Boilers

Products Specification

| Products Name | 317L Stainless Steel Plate |

| Main Grades | Stainless Steel J1, J2, J4, 201, 202, 301, 304, 304H, 304L, 309, 309S, 310, 310S, 316, 316L, 316TI, 317L, 321, 321H, 347, 409, 410, 410S, 420, 430, 441, 904L,630,631,254SMO,654SMO,253MA,2205,2507.etc |

| Thickness | 0.6 - 30.0mm |

| Width | 1250mm,1500mm ,1800mm,2000mm, or custom other size as request |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, AS PER CUSTOMER’S REQUIREMENT |

| Type of Material | Laser Cutting |

| Form | Plate / coil |

| Test Certificate | Yes. |

| Finish | NO.1, 2B, 2D, 2H, 2R, No.4, HAIRLINE, SCOTCH BRITE, SATIN FINISH, NO.8, BA. |

| Brand | TISCO, LISCO,BAOSTEEL , POSCO, JISCO |

316H Stainless Steel: An Overview

316H is a high-carbon variant of the widely used 316 austenitic stainless steel, engineered to deliver enhanced high-temperature strength and corrosion resistance in demanding industrial applications. Its chemical composition and mechanical properties make it a preferred choice in environments where both heat resistance and durability are critical.

Chemical Composition

316H retains the core alloying elements of 316 but with a higher carbon content (0.04–0.10%, compared to 316’s maximum of 0.08%), which strengthens its grain structure at elevated temperatures. Key components include:

- Chromium (16.0–18.0%): Enhances corrosion resistance by forming a protective oxide layer.

- Nickel (10.0–14.0%): Stabilizes the austenitic structure, improving ductility and toughness.

- Molybdenum (2.0–3.0%): Boosts resistance to pitting and crevice corrosion, especially in chloride-rich environments (e.g., seawater, chemical processing).

- Carbon (0.04–0.10%): Increases high-temperature strength, preventing grain boundary 弱化 under prolonged heat exposure.

Mechanical Properties

- Tensile Strength: 515 MPa (minimum).

- Yield Strength: 205 MPa (minimum).

- Elongation: 40% (minimum), ensuring good formability.

- Temperature Resistance: Performs reliably up to 800°C (1472°F), making it suitable for high-heat applications like furnace components or exhaust systems.

Key Advantages

- Superior High-Temperature Strength: The higher carbon content resists creep (slow deformation under stress) at elevated temperatures, outperforming standard 316 in long-term heat exposure.

- Excellent Corrosion Resistance: Molybdenum addition provides resistance to chloride-induced corrosion, making it ideal for marine, chemical, and offshore environments.

- Weldability: Compatible with common welding techniques (e.g., TIG, MIG), though post-weld annealing may be required for maximum corrosion resistance in critical applications.

Typical Applications

- Petrochemical and chemical processing equipment (reactors, pipelines).

- Power generation systems (boiler components, turbine parts).

- Marine engineering (propeller shafts, offshore platforms).

- High-temperature industrial furnaces and heat exchangers.

![]()

![]()

![]()

![]()

Recommended Products