-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

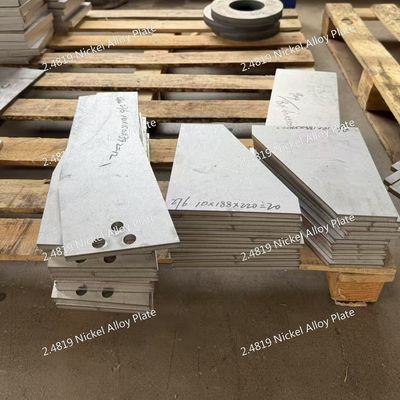

DIN 17744 W.Nr. 2.4819 Nickel Alloy Plate Sheet 1.0 - 30.0mm Laser Cutting Any Size

| Products | Nickel Alloy Plate | Grade | 2.4819 |

|---|---|---|---|

| Thickness | 1.0 - 30.0mm | Width | 1000mm 1219mm 1500mm |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | 2B NO.1 |

| Highlight | 1mm nickel alloy sheet,30mm nickel alloy sheet,Laser Cutting nickel alloy sheet |

||

DIN 17744 W.Nr. 2.4819 Nickel Alloy Plate Sheet 1.0 - 30.0mm Laser Cutting Any Size

Quick Informations

| Grade | Hastelloy C276 / 2.4819 | Type | Sheet, Plate |

| Thickness | 1.0-25.0mm | Width | 1219mm,1500mm |

| Length | Within 6m | Service | Laser Cutting |

More Specification Informations

| Products Name | DIN 2.4819 Nickel Alloy Sheet , Plate |

| Thickness | cold rolled 1.0 - 3.0mm, hot rolled 4.0 - 25.0mm |

| Standard Size | 1000*2000mm,1219*2438mm,1500*6000mm |

| Surface | 2B, NO.1 |

| Brand | DELTA |

| Service | Laser cutting |

| MOQ | 2 Kgs |

| Other Type | round bar, strip,coil,pipe.etc |

| Packing | waterproof paper and wooden pallets, wooden box |

| Loading Port | Shanghai Port |

| Price term | EXW,FOB,CIF,CFR |

| Deliver time | within 12 days |

Product Information: Nickel Alloy Plate (UNS N10276 / DIN 2.4819 / Hastelloy C-276)

- Material: Nickel-Chromium-Molybdenum-Tungsten Alloy

- Common Designations: UNS N10276, W.Nr. 2.4819, ASTM B575, ASME SB575, Hastelloy C-276

Key Characteristics

-

Exceptional Corrosion Resistance: Outstanding performance in severely corrosive environments, including:

-

Strong oxidizing agents (e.g., chlorine, hypochlorite, ferric chloride, cupric chloride)

-

Reducing acids (e.g., sulfuric, hydrochloric, phosphoric)

-

Chloride-containing solutions (resists pitting, crevice corrosion, stress corrosion cracking)

-

Acetic acid, formic acid, wet chlorine gas, solvents.

-

-

Excellent Fabricability: Can be readily formed and welded using standard techniques.

-

High Temperature Stability: Maintains strength and corrosion resistance at elevated temperatures.

-

Versatility: One of the most widely used nickel alloys for handling the most aggressive chemical process conditions.

Chemical Composition (Typical % wt.)

| Element | Min. | Max. |

|---|---|---|

| Nickel (Ni) | Balance | |

| Chromium (Cr) | 14.5 | 16.5 |

| Molybdenum (Mo) | 15.0 | 17.0 |

| Iron (Fe) | 4.0 | 7.0 |

| Tungsten (W) | 3.0 | 4.5 |

| Cobalt (Co) | 2.5 | |

| Manganese (Mn) | 1.0 | |

| Vanadium (V) | 0.35 | |

| Silicon (Si) | 0.08 | |

| Carbon (C) | 0.01 | |

| Phosphorus (P) | 0.04 | |

| Sulfur (S) | 0.03 |

Mechanical Properties (Typical - Annealed Condition)

-

Tensile Strength: ≥ 690 MPa (≥ 100 ksi)

-

Yield Strength (0.2% Offset): ≥ 283 MPa (≥ 41 ksi)

-

Elongation (% in 50mm / 2"): ≥ 40%

-

Hardness (Rockwell B): ≤ 100 HRB

Physical Properties

-

Density: 8.89 g/cm³ (0.321 lb/in³)

-

Melting Range: ~ 1325 - 1370 °C (~ 2420 - 2500 °F)

Applications (Typical Uses for Plate)

-

Chemical processing equipment (reactors, vessels, columns, piping systems)

-

Pollution control scrubbers and ducting

-

Pulp and paper digesters and bleach plants

-

Pharmaceutical manufacturing equipment

-

Waste treatment systems

-

Flue gas desulfurization (FGD) systems

-

Marine engineering components

-

Acid production and handling

Available Forms & Specifications

-

Form: Plate (Hot Rolled or Cold Rolled & Annealed)

-

Thickness Range: Typically 5mm (0.187") to 150mm (6") or more (subject to mill capability).

-

Width & Length: Standard mill sizes, can often be cut-to-order.

-

Standards: Supplied to ASTM B575, ASME SB575, EN 10204 3.1/3.2, or equivalent customer specifications.

Key Advantages

-

Proven Performance: Industry standard for severe corrosive service.

-

Broad Chemical Resistance: Handles both oxidizing and reducing media.

-

Weldability: Can be readily welded by common methods (TIG, MIG, SMAW) without post-weld heat treatment under most conditions.

-

High Strength & Toughness: Reliable performance under stress.

![]()

![]()

![]()

![]()