-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

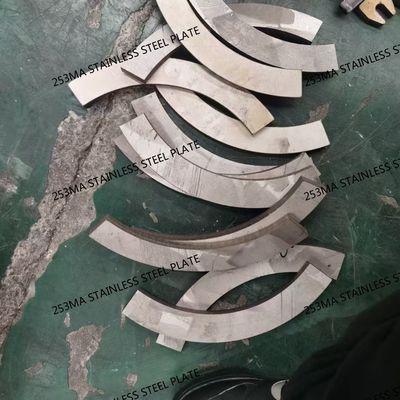

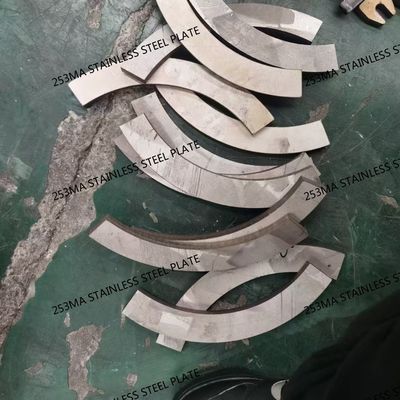

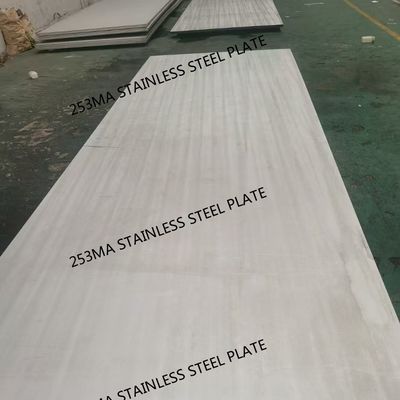

253MA Stainless Steel Plate Heat Resistant Up To 1150°C For Heat Treatment Equipment Exhaust Systems

| Place of Origin | China |

|---|---|

| Brand Name | TISCO BAOSTEEL |

| Certification | ISO |

| Model Number | 253ma / S30815 |

| Minimum Order Quantity | 500 kgs |

| Price | 1700- 2000 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | T/T, Western Union |

| Supply Ability | 20Ton per week |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products | Stainless Steel Plate | Grade | 253ma / S30815 |

|---|---|---|---|

| Thickness | 3.0 - 80.0mm | Width | 1500mm 1800mm 2000mm |

| Surface | NO.1 | Brand | BAOSTEEL TISCO |

| Standard | ASTM A240/240M | Loading Port | Shanghai Port |

| Highlight | Heat Treatment Equipment Stainless Steel Plate,253MA Stainless Steel Plate,Exhaust Systems Stainless Steel Plate |

||

253MA Stainless Steel Plate Heat Resistant up to 1150°C, Ideal for Heat Treatment Equipment & Exhaust Systems

Products Specification

| Products Name | 253ma Stainless Steel Plate |

| Main Grades | Stainless Steel J1, J2, J4, 201, 202, 301, 304, 304H, 304L, 309, 309S, 310, 310S, 316, 316L, 316TI, 321, 321H, 347, 409, 410, 410S, 420, 430, 441, 904L,630,631,254SMO,253MA,2205,2507.etc |

| Thickness | 3.0 - 80.0mm |

| Width | 1250mm,1500mm ,1800mm,2000mm, or custom other size as request |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, AS PER CUSTOMER’S REQUIREMENT |

| Type of Material | Laser Cutting |

| Form | Plate / coil |

| Test Certificate | Yes. |

| Finish | NO.1, 2B, 2D, 2H, 2R, No.4, HAIRLINE, SCOTCH BRITE, SATIN FINISH, NO.8, BA. |

| Brand | TISCO, LISCO,BAOSTEEL , POSCO, JISCO |

1. Introduction

253MA® is a patented, nitrogen-enhanced austenitic stainless steel engineered by Outokumpu for extreme thermal cycling environments (up to 1150°C/2100°F). Its cerium micro-alloying forms self-healing oxide layers, delivering superior oxidation/spalling resistance versus 310S/309S grades. Ideal for cost-sensitive replacements of nickel alloys in corrosive, high-stress thermal applications.

2. Key Performance Data

| Parameter | Value |

|---|---|

| Chemical Composition | |

| Cr | 20.0–22.0% |

| Ni | 10.0–12.0% |

| N | 0.14–0.20% |

| Ce | 0.03–0.08% |

| Mechanical (Annealed) | |

| Hardness (HV) | ≤ 230 |

| Impact Toughness (20°C) | ≥ 100 J |

| Thermal | |

| Thermal Expansion (20–1000°C) | 16.5 μm/m·°C |

| Thermal Conductivity (600°C) | 26 W/m·K |

3. Standards & Compliance

-

Material Standards:

-

ASTM A240/A480 (Pressure Vessel)

-

EN 10095 (Heat-Resisting Steels)

-

ASME II Part A (Boiler Code)

-

-

Certifications:

-

EN 10204 3.2 Certification

-

NORSOK M650 (Oil & Gas)

-

ISO 3834-2 (Welding Quality)

-

4. Specifications & Availability

| Attribute | Details |

|---|---|

| Thickness | 0.3 mm – 150 mm (Custom >100 mm) |

| Width | 600–2500 mm (Tolerance: ±5 mm) |

| Surface Finish | New: N4 (Brushed), HL (Hairline) |

| Form | Quarto Plates, Precision-Shim Stock |

| Tolerances | EN 10029-1.4301 Class A (Thickness) |

5. Packaging Innovations

-

Anti-Corrosion Packaging:

-

3-Layer Protection: VCI Paper + PE Film + Desiccant

-

Sealed Edges with Silica Gel Capsules

-

-

Export Security:

-

Steel-Banded Waterproof Wooden Crates (IP67 Rating)

-

RFID Tracking Tags + QR-Coded Labels

-

-

Custom Options:

-

Vacuum-Sealed Units (For Aerospace)

-

Non-Marking Rubber-Separated Stacks

-

6. Advanced Applications

| Industry | Specific Use Cases |

|---|---|

| Energy | Advanced-Ultra Supercritical (A-USC) Boiler Tubes |

| Aerospace | Afterburner Components, Exhaust Systems |

| Hydrogen | Electrolyzer Hot-Box Components |

| Additive Mfg | Powder Bed Fusion (PBF) Base Plates |

| Nuclear | Gen IV Reactor Heat Exchangers |

7. Comparative Advantages

-

vs. 310S: 30% higher creep strength at 1000°C

-

vs. Alloy 800H: 40% cost reduction with comparable oxidation resistance

-

Unique Capability: Withstands cyclic sulfidation in waste-to-energy plants

8. Technical Notes

-

Fabrication:

-

Laser Cutting: N₂-Assisted for Oxide-Free Edges

-

Post-Weld Heat Treatment: 1100°C Water Quench Required

-

-

Compliance: REACH SVHC-Free, RoHS 3 Compliant

Disclaimer: 253MA® is a registered trademark of Outokumpu Oyj. Properties valid for solution-annealed condition. Contact for cryogenic (-196°C) performance data.

![]()

![]()

![]()

![]()