-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

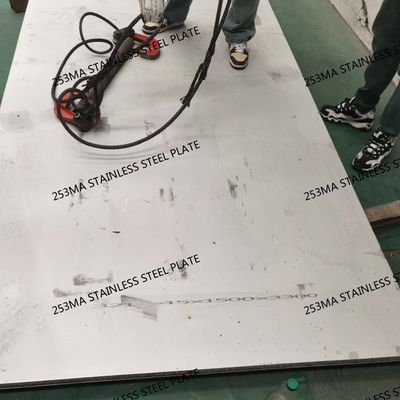

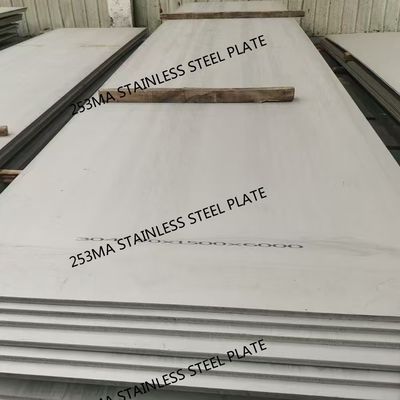

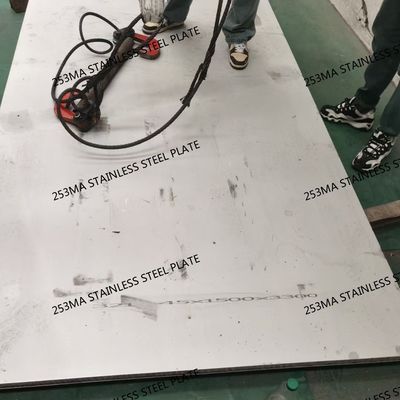

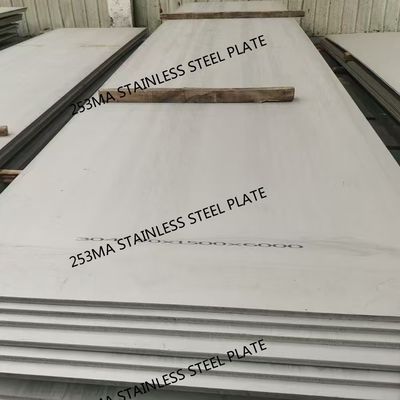

Custom Cut 253MA Stainless Steel Plate Precision-Machined Heat Treated For Aerospace And High-Temperature Industrial Use

| Place of Origin | China |

|---|---|

| Brand Name | TISCO BAOSTEEL |

| Certification | ISO |

| Model Number | 253ma / S30815 |

| Minimum Order Quantity | 500 kgs |

| Price | 1700- 2000 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | T/T, Western Union |

| Supply Ability | 20Ton per week |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products | Stainless Steel Plate | Grade | 253ma / S30815 |

|---|---|---|---|

| Thickness | 3.0 - 80.0mm | Width | 1500mm 1800mm 2000mm |

| Surface | NO.1 | Brand | BAOSTEEL TISCO |

| Standard | ASTM A240/240M | Loading Port | Shanghai Port |

| Highlight | Precision-Machined Stainless Steel Plate,Custom Cut Stainless Steel Plate,253MA Stainless Steel Plate |

||

Custom Cut 253MA Stainless Steel Plate Precision-Machined Heat Treated for Aerospace and High-Temperature Industrial Use

Products Specification

| Products Name | 253ma Stainless Steel Plate |

| Main Grades | Stainless Steel J1, J2, J4, 201, 202, 301, 304, 304H, 304L, 309, 309S, 310, 310S, 316, 316L, 316TI, 321, 321H, 347, 409, 410, 410S, 420, 430, 441, 904L,630,631,254SMO,253MA,2205,2507.etc |

| Thickness | 3.0 - 80.0mm |

| Width | 1250mm,1500mm ,1800mm,2000mm, or custom other size as request |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, AS PER CUSTOMER’S REQUIREMENT |

| Type of Material | Laser Cutting |

| Form | Plate / coil |

| Test Certificate | Yes. |

| Finish | NO.1, 2B, 2D, 2H, 2R, No.4, HAIRLINE, SCOTCH BRITE, SATIN FINISH, NO.8, BA. |

| Brand | TISCO, LISCO,BAOSTEEL , POSCO, JISCO |

PRODUCT: 253MA® (UNS S30815) STAINLESS STEEL PLATE

1. Introduction:

253MA® is a high-performance, heat-resistant austenitic stainless steel plate developed for extreme temperature environments. Its unique composition, enhanced with nitrogen and rare earth elements (Cerium), provides exceptional oxidation resistance, creep strength, and thermal stability up to 1150°C (2100°F). Ideal for cyclic heating applications, it outperforms standard grades like 310S and serves as a cost-effective alternative to nickel alloys in aggressive industrial settings.

2. Key Parameters:

| Property | Value (Metric) | Value (Imperial) |

|---|---|---|

| Chemical Composition (wt%) | ||

| Carbon (C) | 0.05–0.10 | |

| Silicon (Si) | 1.4–2.0 | |

| Chromium (Cr) | 20.0–22.0 | |

| Nickel (Ni) | 10.0–12.0 | |

| Nitrogen (N) | 0.14–0.20 | |

| Cerium (Ce) | 0.03–0.08 | |

| Manganese (Mn) | ≤ 0.80 | |

| Mechanical Properties (Annealed Plate) | ||

| Tensile Strength | ≥ 600 MPa | ≥ 87,000 psi |

| Yield Strength (0.2%) | ≥ 310 MPa | ≥ 45,000 psi |

| Elongation (50mm) | ≥ 40% | ≥ 40% |

| Hardness (Brinell) | ≤ 217 HBW | ≤ 217 HBW |

| High-Temperature Performance | ||

| Max Continuous Service | 1100°C (2012°F) | |

| Max Intermittent Service | 1150°C (2100°F) | |

| Scaling Resistance | Superior to 310S above 1000°C |

3. Standards & Certifications:

-

Material Standards:

ASTM A240/A480, ASME SA240, EN 10028-7, UNS S30815, EN 1.4835 -

Certifications:

Mill Test Certificates (EN 10204 3.1/3.2), PED 2014/68/EU, ISO 9001 -

Origin: EU/US/Japan mills (Specify upon request)

4. Specifications:

| Attribute | Range |

|---|---|

| Thickness | 0.5mm – 100mm (0.02" – 4") |

| Width | 1000mm – 2500mm (39" – 98") |

| Length | 2000mm – 12000mm (78" – 472") |

| Surface Finish | No.1 (HRAP), 2B (Cold-Rolled), BA, #8 |

| Condition | Annealed & Pickled |

| Edge | Mill Edge, Trimmed Edge, or Sheared |

5. Packaging:

-

Export Package:

-

Wooden crates with waterproof wrapping.

-

Plate surfaces separated by PE film/VCI paper to prevent scratching & corrosion.

-

Edges protected with corner guards.

-

Clearly labeled with grade, size, heat no., weight, and direction.

-

-

Standard Package:

-

Bundled with steel straps + moisture-resistant coating.

-

-

Bare Package:

-

Minimal wrapping for domestic shipments (upon request).

-

-

Customization: Palletized, shrink-wrapped, or container-optimized.

6. Applications:

253MA® plates are engineered for severe thermal and corrosive environments:

-

Industrial Furnaces: Radiant tubes, burner nozzles, furnace conveyors.

-

Power Generation: Boiler components, heat exchangers, flue gas systems.

-

Cement & Chemical Plants: Kiln internals, cyclone preheaters, cooler grates.

-

Petrochemical: Cracking tubes, reformers, thermal oxidizers.

-

Waste Processing: Incinerator grates, ash-handling systems.

-

Heat Treatment: Fixtures, baskets, muffles.

7. Notes:

-

Welding: Use matching filler (e.g., Sandvik 23.12.L). Low heat input recommended.

-

Machining: Optimize with sharp tools and rigid setups (work-hardens rapidly).

-

Compliance: RoHS/REACH compliant.

-

Lead Time: 2–8 weeks (stock-dependent).

-

MOQ: 1 ton (custom sizes negotiable).

![]()

![]()

![]()

![]()