All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

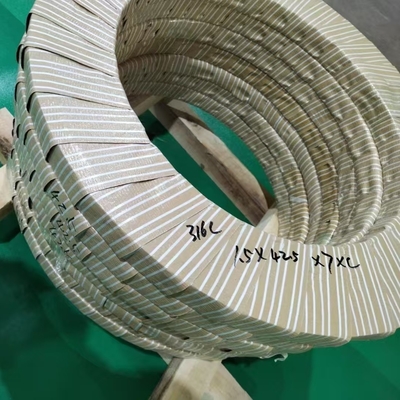

316L / 1.4404 Stainless Steel Narrow Strips 0.5 - 3.0mm Cold Rolled SS Roll

| Place of Origin | China |

|---|---|

| Brand Name | TISCO |

| Certification | ISO |

| Model Number | 316L / 1.4404 |

| Minimum Order Quantity | 2 Ton |

| Price | 2500 - 3450 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Products | Stainless Steel Strip | Thickness | 0.5-3.0mm |

|---|---|---|---|

| Width | Within 1500mm | MOQ | 500 Kgs |

| Grade | 200 Series 300 Series 300 Series | Surface | BA 2B NO.4 HL 8K NO.1 |

| Standard | ASTM EN GB JIS | Packing | Wooden Frame And Water Proof Paper |

| Highlight | 316L Stainless Steel Narrow Strips,Cold Rolled Stainless Steel Narrow Strips,1.4404 Stainless Steel Narrow Strips |

||

Product Description

316L / 1.4404 Stainless Steel Narrow Strips 0.5 - 3.0mm Cold Rolled SS Roll

Products Specification

| Product Name | 316L Stainless Steel Strips |

| Length | As required |

| Width | 3mm-1219mm or as required |

| Thickness | 0.15 - 3.0mm or as required |

| Standard | AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc. |

| Technique | Hot rolled / cold rolled |

| Surface Treatment | 2B or according to customer requirement |

| Thickness tolerance | ±0.01mm |

| Material | 201, 202, 301, 302, 303, 304, 304L, 304H, 310S, 316, 316L, 317L, 321,310S 309S, 410, 410S,420, 430, 431, 440A,904L,2205,2507 |

| Application | It is widely used in high temperature applications, medical devices, building materials, chemistry, food industry, agriculture, ship components.It also applies to food, beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, and screen. |

| MOQ | 1tons.We also can accept sample order. |

| Shipment time | Within 15-20 workdays after receiving deposit or L/C |

| Export packing | Waterproof paper, and steel strip packed.Standard Export Seaworthy Package.Suit for all kinds of transport,or as required |

| Capacity | 250,000 tons/year |

1. Introduction

The 316L stainless steel sheet is a low-carbon variant of the 316 stainless steel, renowned for its superior corrosion resistance, especially in harsh environments. “L” in its name denotes “low carbon,” which significantly reduces the risk of carbide precipitation during welding, thereby enhancing intergranular corrosion resistance.

2. Key Properties

2.1 Corrosion Resistance

- General Corrosion: Exhibits excellent resistance to a wide range of corrosive media, including acids, alkalis, and salts. It outperforms 304 stainless steel in chloride - containing environments, making it ideal for marine applications and exposure to industrial chemicals.

- Pitting and Crevice Corrosion: With the addition of molybdenum, 316L shows enhanced resistance to pitting and crevice corrosion, which are common in stagnant or oxygen - deprived environments.

2.2 Mechanical Properties

- Tensile Strength: Typically ranges from 485 - 620 MPa (70,345 - 89,923 psi).

- Yield Strength: Around 170 - 205 MPa (24,656 - 29,733 psi) in the annealed condition.

- Elongation: Offers good ductility with an elongation of ≥40% in the annealed state, allowing for various forming operations without cracking.

2.3 Chemical Composition

3. Fabrication and Formability

316L stainless steel sheets can be easily fabricated using common metalworking processes such as cutting, bending, rolling, and welding. Its low - carbon content ensures that welding operations do not significantly compromise its corrosion resistance. Suitable welding methods include TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, and stick welding.

4. Applications

- Marine Industry: Used for shipbuilding components, offshore platforms, and marine hardware due to its excellent resistance to seawater corrosion.

- Food and Beverage Industry: Ideal for equipment and storage tanks as it complies with hygiene standards and resists corrosion from food - processing chemicals.

- Pharmaceutical Industry: Applied in the manufacturing of pharmaceutical equipment and facilities, where strict hygiene and corrosion resistance are required.

- Chemical Processing: Suitable for reactors, pipelines, and storage vessels handling corrosive chemicals.

- Architecture: Employed in architectural applications, especially in coastal areas or regions with high pollution, for cladding, handrails, and decorative elements.

5. Surface Finishes

Available in various surface finishes to meet different application requirements:

- 2B Finish: A smooth, bright finish achieved by cold rolling and annealing, followed by skin - passing with light reduction. It is commonly used for general - purpose applications.

- No. 4 Finish: A satin - like finish obtained by mechanical polishing with abrasive belts, often used in architectural and decorative applications.

- Mirror Finish: A highly reflective finish achieved through multiple stages of polishing, suitable for high - end decorative purposes.

6. Standards and Certifications

Complies with international standards such as ASTM A240, EN 10088 - 2, and JIS G4305, ensuring consistent quality and performance.

7. Maintenance

Requires minimal maintenance. Regular cleaning with mild detergents and water can remove surface contaminants and maintain its corrosion - resistant properties. Avoid using abrasive cleaners or materials that may scratch the surface, as scratches can potentially act as sites for corrosion initiation.

8. Packaging and Delivery

Sheets are carefully packaged to prevent scratches and damage during transportation. Options include wrapping in protective films, interleaving with paper, and securing in wooden crates. Delivery can be arranged worldwide, with customized shipping solutions to meet specific customer needs.

![]()

![]()

![]()

![]()

Recommended Products