-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

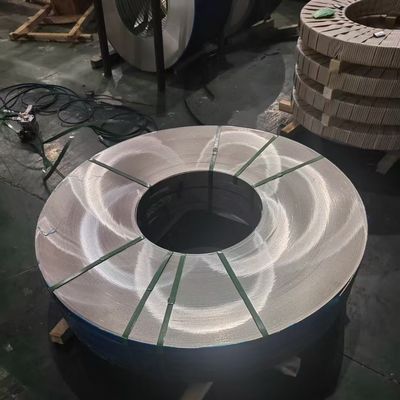

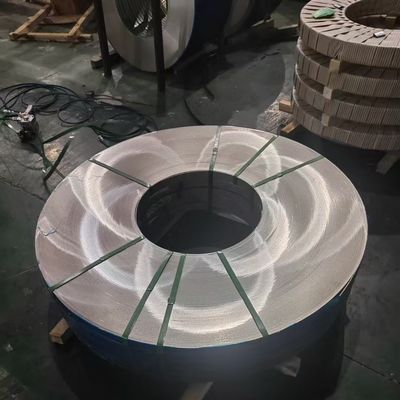

Grade 444 Stainless Steel Strip High Corrosion Resistance Precision Cold Rolled

| Products | Stainless Steel Strip | Thickness | 0.5-3.0mm |

|---|---|---|---|

| Width | Within 1500mm | MOQ | 500 Kgs |

| Grade | 200 Series 300 Series 400 Series | Surface | BA 2B |

| Standard | ASTM EN GB JIS | Packing | Wooden Frame And Water Proof Paper |

| Highlight | High Corrosion Resistance Stainless Strip,Grade 444 Stainless Steel Strip,Precision Cold Rolled Steel Strip |

||

Products Specification

| Product Name | SUS444 Stainless Steel Strips |

| Length | As required |

| Width | 3mm-1219mm or as required |

| Thickness | 0.15 - 3.0mm or as required |

| Standard | AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc. |

| Technique | Hot rolled / cold rolled |

| Surface Treatment | 2B or according to customer requirement |

| Thickness tolerance | ±0.01mm |

| Material | 201, 202, 301, 302, 303, 304, 304L, 304H, 310S, 316, 316L, 317L, 321,310S 309S, 410, 410S,420, 430, 431, 440A,444,904L,2205,2507,630,631.etc |

| Application | It is widely used in high temperature applications, medical devices, building materials, chemistry, food industry, agriculture, ship components.It also applies to food, beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, and screen. |

| MOQ | 1tons.We also can accept sample order. |

| Shipment time | Within 15-20 workdays after receiving deposit or L/C |

| Export packing | Waterproof paper, and steel strip packed.Standard Export Seaworthy Package.Suit for all kinds of transport,or as required |

| Capacity | 250,000 tons/year |

Product Name: 444 Stainless Steel Strip

Material Grade: UNS S44400 / EN 1.4521

Product Overview

444 stainless steel strip is a high-chromium ferritic stainless steel known for its excellent corrosion resistance, particularly in chloride-containing environments. With a low carbon content and added molybdenum, this alloy offers superior resistance to stress corrosion cracking (SCC), pitting, and crevice corrosion. It is a cost-effective alternative to austenitic grades like 304/316 in specific applications.

Key Features

-

Corrosion Resistance: Performs exceptionally well in acidic, alkaline, and chloride-exposed environments.

-

Heat Resistance: Suitable for high-temperature applications up to 400°C (752°F).

-

Weldability: Low carbon content minimizes sensitization and ensures good weldability.

-

Formability: Balanced ductility for bending and forming operations.

-

Magnetic Properties: Fully magnetic due to its ferritic structure.

Chemical Composition

| Element | Composition (%) |

|---|---|

| Chromium (Cr) | 17.5–19.5 |

| Molybdenum (Mo) | 1.75–2.5 |

| Nickel (Ni) | ≤1.0 |

| Manganese (Mn) | ≤1.0 |

| Silicon (Si) | ≤1.0 |

| Carbon (C) | ≤0.025 |

| Nitrogen (N) | ≤0.035 |

| Iron (Fe) | Balance |

Mechanical Properties

-

Tensile Strength: 415 MPa (60 ksi) min

-

Yield Strength: 275 MPa (40 ksi) min

-

Elongation: 20% min (in 50 mm)

-

Hardness: ≤200 HV (Annealed Condition)

Physical Properties

-

Density: 7.75 g/cm³

-

Melting Point: 1427–1510°C (2600–2750°F)

-

Thermal Conductivity: 24.9 W/m·K (at 100°C)

-

Electrical Resistivity: 0.60 μΩ·m

Surface Finish Options

-

2B: Bright cold-rolled finish

-

BA (Bright Annealed): Reflective, smooth surface

-

No. 3/4: Brushed or polished finishes (customizable)

-

Matte: Dull finish for specific industrial uses

Available Dimensions

-

Thickness: 0.1 mm – 3.0 mm (0.004" – 0.118")

-

Width: 10 mm – 600 mm (0.4" – 24")

-

Length: Custom coils or cut-to-length sheets

Typical Applications

-

Automotive exhaust systems and catalytic converter shells

-

Heat exchangers, water heaters, and solar thermal systems

-

Food processing equipment and brewery tanks

-

Architectural trim and coastal construction components

-

Chemical storage tanks and piping systems

Advantages Over Competing Grades

-

Cost Savings: Lower nickel content reduces material costs compared to 316L.

-

Stress Corrosion Resistance: Outperforms 304/316 in high-chloride environments.

-

Thermal Expansion: Lower thermal expansion than austenitic grades, ideal for thermal cycling.

Packaging

-

Protected with anti-rust paper or plastic film

-

Securely packed in wooden crates or steel coil racks

-

Custom packaging available upon request

Certifications

-

Complies with ASTM A240, JIS G4304, and EN 10088-2 standards

-

Mill test certificates (MTC) provided with shipment

Notes

-

Custom sizes, tempers (annealed, hard rolled), and surface treatments available.

-

Contact us for technical support, sample requests, or volume pricing.

![]()

![]()

![]()

![]()