-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

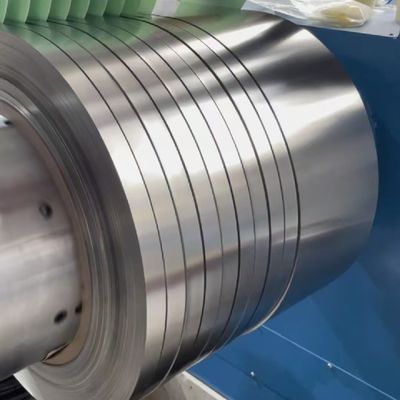

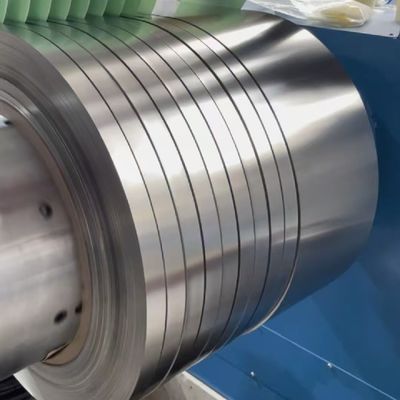

304 Stainless Steel Strip 1/4H 1/2H 3/4H FH Thickness 0.4mm 0.5mm 0.6mm Spring Belt

| Place of Origin | China |

|---|---|

| Brand Name | TISCO |

| Certification | ISO |

| Model Number | 200Series 300 Series 400 Series C276 904L,Monel 400 K500 |

| Minimum Order Quantity | 2 Ton |

| Price | 1000 - 2500 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

| Products | Stainless Steel Strip | Thickness | 0.01 - 3.0mm |

|---|---|---|---|

| Width | Within 1500mm | Hardness | 1/4H 1/2H 3/4H FH |

| Grade | 201 304 316 310S 410 420 430.etc | Surface | BA 2B NO.4 HL 8K NO.1 |

| Standard | ASTM EN GB JIS | Packing | Wooden Frame And Water Proof Paper |

| Highlight | 0.5mm 304 Stainless Steel Strip,0.6mm 304 Stainless Steel Strip,0.4mm 304 Stainless Steel Strip |

||

304 Stainless Steel Strip 1/4H 1/2H 3/4H FH Thickness 0.4mm 0.5mm 0.6mm Spring Belt

Products Specification

| Product Name | Stainless Steel Strip |

|---|---|

| Thickness | 0.01mm-3.0mm or as required |

| Width | 4-1500mm or as required |

| Length | As request |

| Standard | ASME, ASTM, EN, BS, GB, DIN, JIS, etc |

| Material | 201 301 304 309S 310S 316L 317L 321 409L 410 416 420 430 439 441 444 904L C276.etc |

| Hardness | Soft , 1/4H , 1/2H , 3/4H,FH |

| Surface | 2B, BA, 2D, 6K,NO.1 or special surface as request |

| Packaging | Standard export sea-worthy packing |

| Technique | Hot rolled/Cold rolled |

| Delivery time | 7-15 Days |

| Application range | Foodstuff, gas, matallurgy, biology, electron, chemical, petroleum, boiler, nuclear energy,medical equipment, frillizer, etc |

| Note | The other specifications can be produced as per customers' requirements |

The different hardness states of 304 stainless steel strip (1/4H, 1/2H, 3/4H, FH) are mainly achieved through cold rolling processing, and the increase of hardness is accompanied by the decrease of plasticity and toughness. The following are the introduction, parameters, properties and applications of each hardness state:

1. 1/4H (1/4 Hard)

- Hardness: HV 250-310

- Tensile strength: 700-850 MPa

- Elongation: 10-15%

- Properties: mild cold rolling, moderate hardness, both a certain degree of plasticity and toughness.

- Application: Suitable for occasions requiring certain strength and formability, such as architectural decoration, home appliance parts, etc.

2. 1/2H (1/2 Hard)

- Hardness: HV 310-370

- Tensile strength: 850-1000 MPa

- Elongation: 5-10%

- Performance: medium cold rolling, high hardness, plasticity and toughness decreased.

- Application: For applications requiring high strength and moderate formability, such as spring pieces, auto parts, etc.

3. 3/4H (3/4 Hard)

- Hardness: HV 370-430

- Tensile strength: 1000-1150 MPa

- Elongation: 3-8%

- Performance: high cold rolling, further increase in hardness, plasticity and toughness further reduced.

- Application: Suitable for high strength, low formability requirements, such as high strength springs, precision parts, etc.

4. FH (Full Hard)

- Hardness: HV 430 or more

- Tensile strength: 1150-1300 MPa

- Elongation: 1-3%

- Performance: Maximum cold rolling, highest hardness, lowest plasticity and toughness.

- Application: It is used in applications requiring very high strength and almost no molding, such as blades and high-strength structural parts.

How to Choose different Hardness Type

- 1/4H: mild cold rolling, suitable for occasions requiring certain formability.

- 1/2H: Medium cold rolling, suitable for high strength and moderate formability occasions.

- 3/4H: high cold rolling, suitable for occasions with high strength and low formability requirements.

- FH: Maximum cold rolling, suitable for extremely high strength, almost no molding.

The selection must balance strength, hardness and formability according to the specific application needs.

![]()

![]()

![]()

![]()