-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

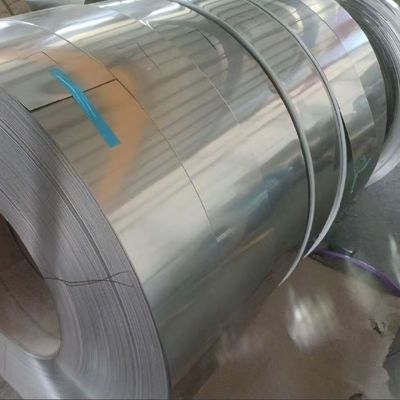

ASTM SA240 301 Stainless Steel Strips 1/4H Hardness HV250-350 Thickness 0.2 - 2.5mm

| Place of Origin | China |

|---|---|

| Brand Name | TISCO |

| Certification | ISO |

| Model Number | 200Series 300 Series 400 Series C276 904L,Monel 400 K500 |

| Minimum Order Quantity | 2 Ton |

| Price | 2400 - 3500 USD/Ton |

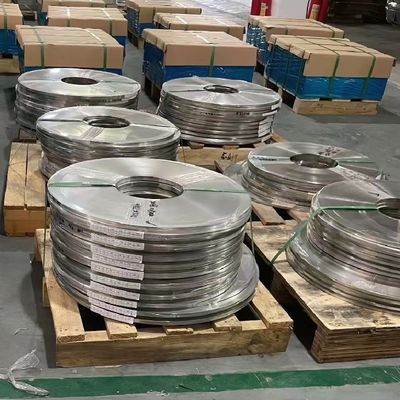

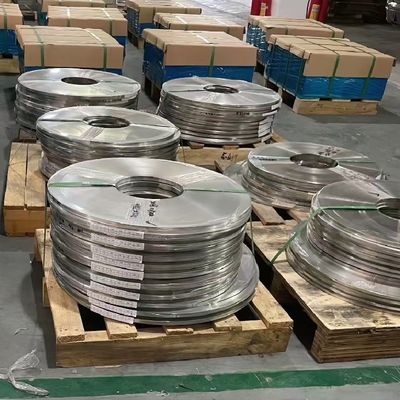

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

| Products | Stainless Steel Strip | Thickness | 0.01 - 3.0mm |

|---|---|---|---|

| Width | Within 1500mm | MOQ | 1000 Kgs |

| Grade | 200 Series 300 Series 400 Series , Nickel Alloy | Surface | BA 2B NO.4 HL 8K NO.1 |

| Standard | ASTM EN GB JIS | Packing | Wooden Frame And Water Proof Paper |

| Highlight | 2.5mm Stainless Steel Strips,ASTM SA240 Stainless Steel Strips,HV250-350 Stainless Steel Strips |

||

ASTM SA240 301 Stainless Steel Strips 1/4H Hardness HV250-350 Thickness 0.2 - 2.5mm

Products Specification

| Product Name | Stainless Steel Strip |

|---|---|

| Thickness | 0.01mm-3.0mm or as required |

| Width | 4-1500mm or as required |

| Length | As request |

| Standard | ASME, ASTM, EN, BS, GB, DIN, JIS, etc |

| Material | 201 301 304 309S 310S 316L 317L 321 409L 410 416 420 430 439 441 444 904L C276.etc |

| Hardness | Soft , 1/4H , 1/2H , 3/4H,FH |

| Surface | 2B, BA, 2D, 6K,NO.1 or special surface as request |

| Packaging | Standard export sea-worthy packing |

| Technique | Hot rolled/Cold rolled |

| Delivery time | 7-15 Days |

| Application range | Foodstuff, gas, matallurgy, biology, electron, chemical, petroleum, boiler, nuclear energy,medical equipment, frillizer, etc |

| Note | The other specifications can be produced as per customers' requirements |

Introduce of 301 Stainless Steel

1/4H hardness of 301 stainless steel is through cold processing (such as cold rolling) to achieve a partially hardened state, with high strength and hardness, while maintaining a certain ductility. This state is suitable for applications requiring moderate strength and good formability.

Main characteristics

Hardness grade:

1/4H: indicates that the material has been hardened by about 25% cold work, between the annealed state (soft state) and the full hard state (H).

Mechanical properties of 1/4H 301 Stainless Steel

- Tensile strength: about 900-1100 MPa

- Yield strength: about 700-900 MPa

- Elongation: about 15-25%

- Hardness: about 250-350 HV

Corrosion resistance:

- 301 stainless steel with 1/4H hardness still has good corrosion resistance in medium corrosive environments, but it is slightly lower than the annealed state.

Processing properties:

- Formability: 1/4H hardness of 301 stainless steel has a certain ductility, suitable for medium complex degree of molding processing.

- Welding: It can be welded, but after welding, it is necessary to perform solid solution treatment to restore corrosion resistance.

Heat treatment:

- Solution treatment: heating to 1010-1120 ° C, then rapid cooling to restore corrosion resistance and processing properties.

Application field:

- Electronic products: mobile phones, computer cases, etc.

- Automobile manufacturing: body structure parts, springs, etc.

- Architectural decoration: curtain wall, decorative strip, etc.

- Aerospace: aircraft structural parts, engine parts, etc.

Sum up

The 1/4H hardness of 301 stainless steel is partially hardened by cold working, has high strength and certain ductility, and is suitable for occasions requiring moderate strength and good formability. Its good corrosion resistance and processing properties make it widely used in electronic products, automobile manufacturing, architectural decoration and other fields. When selecting, its state and heat treatment method should be determined according to specific needs.

![]()

![]()

![]()

![]()