-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

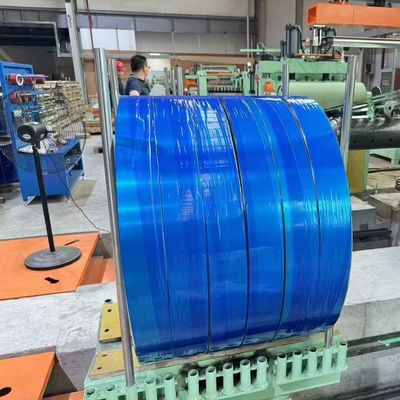

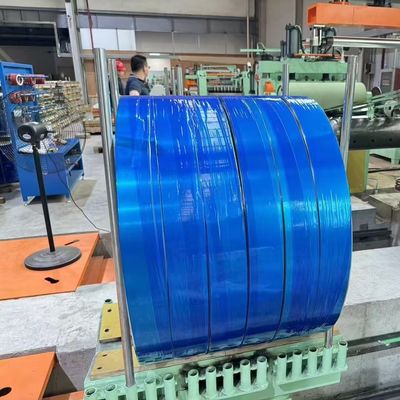

1/4H 1/2H 3/4H FH Grade 301 Stainless Steel Strips Band For Spring

| Place of Origin | China |

|---|---|

| Brand Name | TISCO |

| Certification | ISO |

| Model Number | 301 / UNS S30100 / 1.4310 |

| Minimum Order Quantity | 2 Ton |

| Price | 2380 - 3550 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

| Products | Stainless Steel Strip | Thickness | 0.1-2.5mm |

|---|---|---|---|

| Width | Within 1500mm | MOQ | 500 Kgs |

| Grade | 200 Series 300 Series 300 Series | Surface | BA 2B NO.4 HL 8K NO.1 |

| Standard | ASTM EN GB JIS | Packing | Wooden Frame And Water Proof Paper |

| Highlight | Spring Stainless Steel Strips,FH Grade Stainless Steel Strips,301 Stainless Steel Strips |

||

1/4H 1/2H 3/4H FH Grade 301 Stainless Steel Strips Band Application for Spring

| Product Name | Stainless Steel Strips |

| Length | As required |

| Width | 3mm-1219mm or as required |

| Thickness | 0.15 - 3.0mm or as required |

| Standard | AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc. |

| Technique | Hot rolled / cold rolled |

| Surface Treatment | 2B or according to customer requirement |

| Thickness tolerance | ±0.01mm |

| Material | 201, 202, 301, 302, 303, 304, 304L, 304H, 310S, 316, 316L, 317L, 321,310S 309S, 410, 410S,420, 430, 431, 440A,904L |

| Application | It is widely used in high temperature applications, medical devices, building materials, chemistry, food industry, agriculture, ship components.It also applies to food, beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, and screen. |

| MOQ | 1tons.We also can accept sample order. |

| Shipment time | Within 15-20 workdays after receiving deposit or L/C |

| Export packing | Waterproof paper, and steel strip packed.Standard Export Seaworthy Package.Suit for all kinds of transport,or as required |

| Capacity | 250,000 tons/year |

More Detail Informations of our 301 stainless steel strip

- Grade: 301

- Thickness: 0.1mm 0.15mm 0.2mm 0.25mm 0.3mm 0.4mm 0.5mm 0.6mm 0.8mm 1.0mm 1.2mm 1.5mm 2.0mm 2.5mm

- Width Range: 10 - 1219mm

- Surface: 2B

- Packing: surround by waterproof band and loading on pallets

Introduction of 301 Stainless Steel

Type 301 is an austenitic chromium-nickel stainless steel that provides high strength and good ductility when cold worked. It is a modification of Type 304 in which the chromium and nickel contents are lowered to increase the cold work-hardening range. This permits higher tensile strengths to be achieved by rolling with a lower loss of ductility than with Type 304.

The grade is essentially non-magnetic when annealed. However, when the grade is cold worked, it becomes more magnetic than other standard austenitic stainless steels.

Application:

Aircraft structural parts / trailer bodies / diaphragms / utensils / architectural and automotive trim / automobile wheel covers / roof drainage products / tablewear / storm door frames / conveyor belts / sinks / subway cars

Corrosion Resistanc:

Type 301 exhibits corrosion resistance comparable to Types 302 and 304 in most mild service conditions. Resistance to food service requirements and atmospheric corrosion is excellent. Stress cracking resistance is similar to Type 304. The optimal corrosion resistance is obtained in the cold worked then annealed condition. When Type 301 is heated or cooled slowly through a temperature range of 800 - 1600 °F (427 - 871 °C) without subsequent annealing, it may undergo carbide precipitation that may result in intergranular corrosion

Chemical Composition:

| C% | Mn≤% | P≤% | S≤% | Si≤% | Cr% | Ni≤% |

| 0.15 | 1.00 | 0.045 | 0.030 | 1.00 | 16.00-18.00 | 6.00-8.00 |

Performance:

| T. S. Min | Y. S. Min | EL min% | HARDNESS( max) | ||

| MPa | MPa | 50mm | HBW | HRB | HV |

| 515 | 205 | 40 | 217 | 95 | 220 |

![]()

![]()

![]()

![]()