-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

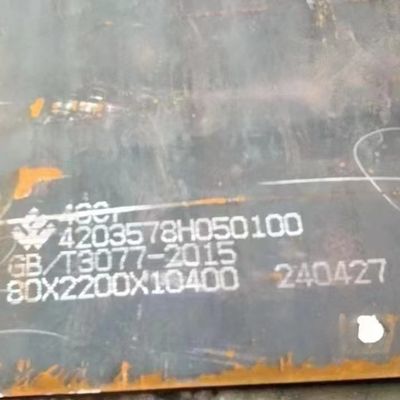

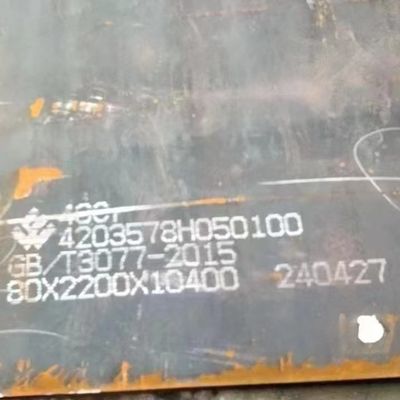

BS EN 42CrMo4 | 1.7225 Alloy Engineering Steel Plate Hot Rolled 30 - 300mm Forged Steel

| Place of Origin | China |

|---|---|

| Brand Name | BAOSTEEL BENSTEEL HBIS XINGCHENG |

| Certification | ISO 9001 |

| Model Number | 42CrMo4 |

| Minimum Order Quantity | 500 kgs |

| Price | 780 - 940USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

| Products | 42CrMo4 Alloy Steel Plate | Thickness | 10.0 - 200.0mm |

|---|---|---|---|

| Width | 1000-2200mm | Length | 2000-12000mm |

| Standard | ASTM EN GB | Other Material | Carbon Steel, Alloy Steel, Stainless Steel |

| Brand | BAOSTEEL XINYU XINGCHENG HBIS | Service | Cutting |

| Highlight | 1.7225 Alloy Engineering Steel Plate,30mm steel plate hot rolled,Forged steel plate hot rolled |

||

BS EN 42CrMo4 | 1.7225 Alloy Engineering Steel Plate Hot Rolled 30 - 300mm Forged Steel

Products Specification of Steel Plate

| Products Name | 42CrMo4 Alloy Steel Plate |

| Thickness | 10.0 - 200.0mm |

| Width | 100 - 2200mm custom cutting any size as request |

| Length | 6m 8m 10m 11.5m 12m or cutting any length as request |

| Standard | ASTM JIS GB EN |

| MOQ | 500 Kgs |

| Deliver time | 7 - 14 days |

| Loading Port | Shanghai Port |

| Packing | wooden pallets |

| Other Grade | AR400 / AR450 / AR500 / AR600 NM400 NM450 NM500 NM600 |

| Service | Cutting, Heat treatment |

BS EN 42CrMo4 Alloy Steel is a common chromium-molybdenum steel that usually used after quenched and tempered, with high intensity, high hardenability. BS EN 42CrMo4 round steel has better performance than 34CrMo4 steel due to the carbon and chromium content is higher. 42CrMo4 alloy steel has higher strength and hardenability. The 42CrMo4 alloy material also has high fatigue strength and good low-temperature impact toughness. The temper brittleness is not obvious.

Although 42CrMo4 steel is more expensive than 41Cr4 steel, it is more preferable in terms of material properties. EN 42CrMo4 alloy engineering steel materials have been widely used in automotive driving elements. Otai Steel is able to supply you prime quality of 42CrMo4 alloy steel materials with wide range.

1.42CrMo4 Alloy Steel Supply Range

42CrMo4 Round bar Sizes: 10mm – 3000mm

Steel 42CrMo4 Flat and Plate: 10mm-1500mm thickness x 200-3000mm width

Other steel shape and sizes available according to your requirements.

Surface condition: Black, rough machined, peeled, turned or other requirements according to your requirements.

2.BS EN 42CrMo4 Alloy Steel Relevant Specifications and Equivalents

| BS EN 10250 | Material No. | DIN | ASTM A29 | JIS G4105 | BS 970-3-1991 | BS 970-1955 | AS 1444 | AFNOR |

| 42CrMo4 | 1.7225 | 38HM | 4140 | SCM440 | 708M40 | EN19A | 4140 | 42CD4 |

3.42CrMo4 Alloy Steel Chemical Composition

| 42CrMo4/1.7225 | C | Mn | Si | P | S | Cr | Mo |

| 0.38-0.45 | 0.60-0.90 | 0.40 max | 0.035 max | 0.035 max | 0.90-1.20 | 0.15-0.30 |

4. DIN 42CrMo4 Alloy Steel Mechanical Properties

| Size Ø mm | Yield stress Rp0.2,N/nn2, min. |

Ultimate tensile Stress, Rm,N/nn2 |

Elongation A5,%, min. |

Hardness HB | Toughness KV, Joule, min. |

||||||||||

| <40 | 750 | 1000-1200 | 11 | 295-355 | 35 at 20ºC | ||||||||||

| 40-95 | 650 | 900-1100 | 12 | 265-325 | 35 at 20ºC | ||||||||||

| >95 | 550 | 800-950 | 13 | 235-295 | 35 at 20ºC | ||||||||||

5. Heat Treatment of 42CrMo4 Steels

Annealing of 42CrMo4 Steels

- Heat steel 42CrMo4 forged steel slowly and thoroughly to 800-850°C;

- Cool slowly in the furnace to the temperature 480°;

- Complete annealing the steel in the air.

Quenched and Tempered (Q+T)

- Heat 42CrMo4 steel slowly to 880°C;

- Soak at this temperature then quench in oil;

- Temper as soon as 42CrMo4 steel reach room temperature (20°C);

- Heat uniformly to the suitable temperature of 560°C;

- Withdraw the 42CrMo4 material from the furnace and cool in the air.

6. Forging of 42CrMo4 Alloy Steel

- Preheat 42CrMo4 engineering steel uniformly and slowly;

- Increase the forging temperature up to 1150-1200°C.

- Always keep the forging temperature above at least 850°C

7.Weldability

Engineering steel 42CrMo4 has only limited weldability. Preheating to 200-300°C is strongly recommended; the upper limit should not be exceeded because of risk for deterioration of the chrome layer.

Alloy steel 42CrMo4 can be friction welded. However, precautions are necessary so as to limit the formation of undesirable microstructures in the welded zone.

8.Application of 42CrMo4 Alloy Steels

EN 42CrMo4 alloy steel is widely used for engineering steel purpose, such as: making various kinds of machinery, automobile, mining spare part, the gearwheel of the engine, the driving gear of supercharger, the connecting rob, the pinchock under the high pressure, parts for power train applications, cold formed fastener components, shafts, gears, drill collars for the oil exploration, etc.

![]()

![]()

![]()

![]()