-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

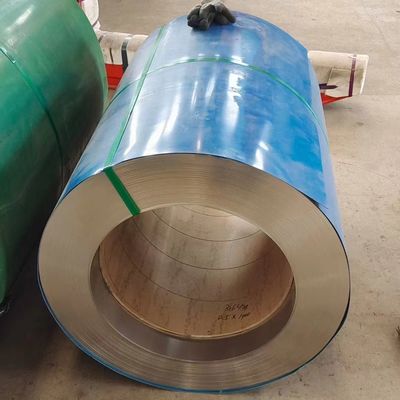

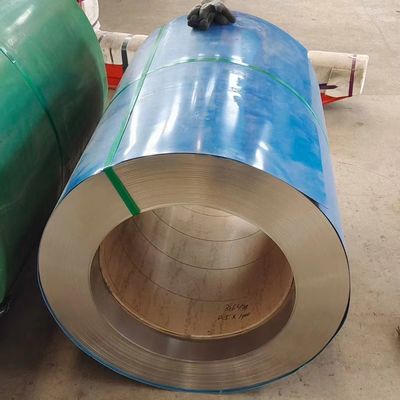

SUS316L / 1.4404 / 316L Stainless Steel Coil Cold Rolled 1219mm 1500mm Width 0.1 - 6.0mm Thickness

| Place of Origin | China |

|---|---|

| Brand Name | TISCO BAOSTEEL POSCO |

| Certification | ISO |

| Model Number | 201 304 309S 310S 316L 317L 321 347 410 420 430.etc |

| Minimum Order Quantity | 2 Ton |

| Price | 2400 - 3500 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

| Products | Stainless Steel Coil | Material | Stainless Steel |

|---|---|---|---|

| Thickness | 0.1 - 16.0mm | Width | 1000mm 1219mm 1500mm |

| Surface | 2B NO.1 NO.4 8K | Grade | 201 304 309S 310S 316L 317L 321 347 410 420 430 436 439 441 444.etc |

| Standard | ASTM EN GB JIS | Service | Cutting |

| Highlight | 1219mm Stainless Steel Coil,1500mm Stainless Steel Coil,1.4404 Cold Rolled Stainless Steel Coil |

||

SUS316L / 1.4404 / 316L Stainless Steel Coil Cold Rolled 1219mm 1500mm Width 0.1 - 6.0mm Thickness

| Product Name | 316L stainless steel coil |

| Grades | 316L/EN 1.4404/SUS316L |

| Hardness | ≤95HRB |

| Thickness | 0.02mm-6.0mm |

| Width | 1.0mm-1500mm |

| Edge | Slit/Mill |

| Quantity Tolerance | ±10% |

| Paper Core Internal Diameter | Ø500mm paper core, special internal diameter core and without paper core on customer request |

| Surface Finish | NO.1/2B/2D/BA/HL/Brushed/6K/8K Mirror,etc |

| Packaging | Wooden Pallet/Wooden Case |

| Payment Terms | 30% TT deposit and 70% balance before shipment, 100% LC at sight |

| Delivery Time | 5-7 working days |

| MOQ | 200Kgs |

| Shipping Port | Shanghai/Ningbo port |

| Sample | The sample of 316L stainless steel coil is available |

Type 316L is an ultra-low carbon version of Type 316 stainless steel that minimizes harmful carbide precipitation from welding.

The process of making stainless steel involves mining chromite from underground mines. Chromite is crushed to produce chromite concentrate. The material is melted in an electric furnace and other raw materials (iron ore, manganese, nickel, etc.) are used for specific stainless steel types.

After melting, the material is formed into slabs and sent to a hot rolling mill. A rolling mill, also called a roughing mill, reduces the thickness of the steel and cools it with water. The material is then transferred to a cold rolling mill.

When the material reaches the cold rolling mill, it is covered with black scale, which is removed by annealing and pickling lines.

Features of 316L stainless steel coils

- Corrosion Resistance

The corrosion resistance of 316L stainless steel coil is better than 304 stainless steel coil, and it has good corrosion resistance in the production process of pulp and paper industry. And 316L stainless steel coil is also resistant to the erosion of the ocean and corrosive industrial atmosphere.

- Heat Resistance

In the intermittent application below 1600 degrees, 316 stainless steel coil has good oxidation resistance.

316L stainless steel coil has better resistance to carbide precipitation than normal 316 grade stainless steel coil.

What are 316L stainless steel coils surface finish?

Through different processing methods of cold rolling and surface reprocessing after rolling, the surface finish of 316L stainless steel coils can have different types.

The surface processing of stainless steel coils have NO.1, 2B, No. 4, HL, No. 6, No. 8, BA, TR hard, Rerolled bright 2H, polishing bright and other surface finishes, etc.

- NO.1: No. 1 surface refers to the surface obtained by heat treatment and pickling after hot rolling of the stainless steel strip. It is to remove the black oxide scale produced during hot rolling and heat treatment by pickling or similar treatment methods. This is No. 1 surface processing. The No.1 surface is silvery white and matt. Mainly used in heat-resistant and corrosion-resistant industries that do not require surface gloss, such as alcohol industry, chemical industry and large containers.

- 2B: The surface of 2B is different from the 2D surface in that it is smoothed with a smooth roller, so it is brighter than the 2D surface. The surface roughness Ra value measured by the instrument is 0.1~0.5μm, which is the most common processing type. This kind of stainless steel strip surface is the most versatile, suitable for general purposes, which is widely used in the chemical, paper, petroleum, medical and other industries, and can also be used as a building curtain wall.

- TR Hard Finish: TR stainless steel is also called hard steel. Its representative steel grades are 304 and 301, they are used for products that require high strength and hardness, such as railway vehicles, conveyor belts, springs and gaskets. The principle is to use the work hardening characteristics of austenitic stainless steel to increase the strength and hardness of the steel plate by cold working methods such as rolling. The hard material uses a few percent to several tens of percent of the mild rolling to replace the mild flatness of the 2B base surface, and no annealing is carried out after rolling. Therefore, the TR hard surface of the hard material is the rolled after cold rolling surface.

- Rerolled Bright 2H: After the rolling process. the stainless steel strips will be processed bright annealing. The strip can be fast cooled by the the continuous annealing line. The traveling speed of the stainless steel strip on the line is around 60m~80m/min. After this step, the surface finish will be 2H rerolled bright.

- No.4: The surface of No. 4 is a fine polished surface finish that is brighter than the surface of No. 3. It is also obtained by polishing the stainless steel cold-rolled stainless steel plate with 2 D or 2 B surface as the base and polishing with abrasive belt with a grain size of 150-180# Machined surface. The surface roughness Ra value measured by the instrument is 0.2~1.5μm. NO.4 surface is widely used in restaurant and kitchen equipment, medical equipment, architectural decoration, containers, etc.

- HL: HL surface is commonly called hairline finish. Japanese JIS standard stipulates that 150-240# abrasive belt is used to polish the continuous hairline-like abrasive surface obtained. In China’s GB3280 standard, the regulations are rather vague. HL surface finish is mostly used for building decoration such as elevators, escalators, and facades.

- No.6: The surface of No. 6 is based on the surface of No. 4 and is further polished with a Tampico brush or abrasive material with a particle size of W63 specified by GB2477 standard. This surface has a good metallic luster and soft performance. The reflection is weak and does not reflect the image. Due to this good property, it is very suitable for making building curtain walls and building fringe decorations, and also widely used as kitchen utensils.

- BA: BA is the surface obtained by bright heat treatment after cold rolling. Bright heat treatment is annealing under a protective atmosphere that guarantees that the surface is not oxidized to preserve the gloss of the cold-rolled surface, and then use a high-precision smoothing roll for light leveling to improve the surface brightness. This surface is close to a mirror finish, and the surface roughness Ra value measured by the instrument is 0.05-0.1μm. BA surface has a wide range of uses and can be used as kitchen utensils, household appliances, medical equipment, auto parts and decorations.

- No.8: No.8 is a mirror-finished surface with the highest reflectivity without abrasive grains. The stainless steel deep processing industry also calls as 8K plates. Generally, BA materials are used as raw materials for mirror finishing only through grinding and polishing. After mirror finishing, the surface is artistic, so it is mostly used in building entrance decoration and interior decoration.

EQUIVALENT STANDARDS OF ASTM 316L STAINLESS STEEL COILS

| AISI | ASTM | EN | DIN | UNS | IS |

|---|---|---|---|---|---|

| 316L | 316L | 1.4404 | X2CrNiMo17-12-2 | S31603 | X02Cr17Ni12Mo2 |

CHEMICAL PROPERTIES OF ASTM 316L STAINLESS STEEL COILS

| C | S | P | Ni | Cr | Si | N | Mn | Mo |

|---|---|---|---|---|---|---|---|---|

| 0.03 | 0.03 | 0.045 | 10.5 | 17 | 0.4 | 1.2 | 2 |

What are 316L stainless steel coils edges?

Mill edge is a non-trimmed edge appearance after hot or cold rolling and annealing/pickling process. It usually leaved an irregular pinhole line on the edge side around 10mm to 15mm.

Slit/slitting edge means we will trim irregular pinhole line on our slitting machine.

What is the standard sea packaging of 316L stainless steel coil?

- Standard export sea packaging:

Waterproof Paper Winding+PVC Film+Strap Banding+Wooden Pallet or Wooden Case; - Customized packaging as your request (Logo or other contents accepted to be printed on the packaging);

- Other special packaging will be designed as customer’s request;

Eye to wall and eye to sky are both available; - By International Express: DHL/UPS/FEDEX/EMS and our own express line;

- By air or By sea;

- Shipping port: Shanghai, Ningbo or as your request.

![]()

![]()

![]()

![]()