-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

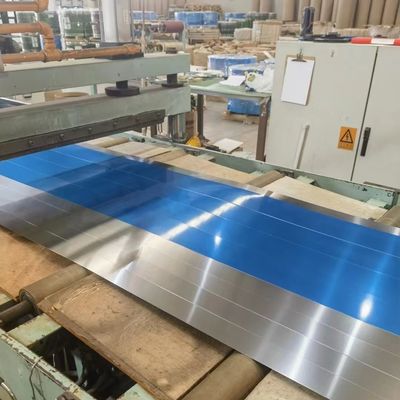

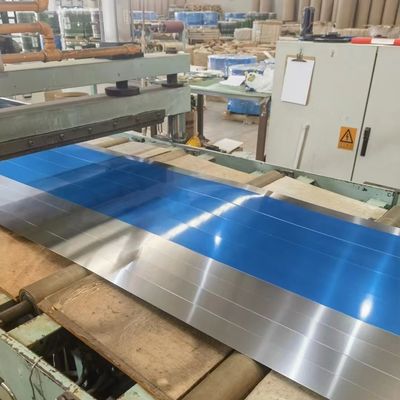

AISI304 Stainless Steel Strips 1/4H 1/2H 3/4H FH Slit Cutting Stainless Steel Coils

| Place of Origin | China |

|---|---|

| Brand Name | TISCO |

| Certification | ISO |

| Model Number | 304 / 1.4301 / AISI304 |

| Minimum Order Quantity | 500 kgs |

| Price | 2388 - 3647 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

| Products | Stainless Steel Strip | Thickness | 0.1-3.0mm |

|---|---|---|---|

| Width | Within 1500mm | MOQ | 500 Kgs |

| Grade | 200 Series 300 Series 300 Series | Surface | BA 2B NO.4 HL 8K NO.1 2D |

| Standard | ASTM EN GB JIS | Packing | Wooden Frame And Water Proof Paper |

| Highlight | aisi stainless steel strip,aisi ss strip coil,precision strip steel |

||

AISI304 Stainless Steel Strips 1/4H 1/2H 3/4H FH Slit Cutting Stainless Steel Coils

| Product Name | Stainless Steel Strips |

| Length | As required |

| Width | 3mm-1219mm or as required |

| Thickness | 0.1 - 3.0mm or as required |

| Standard | AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc. |

| Technique | Hot rolled / cold rolled |

| Surface Treatment | 2B or according to customer requirement |

| Thickness tolerance | ±0.01mm |

| Material | 201, 202, 301, 302, 303, 304, 304L, 304H, 310S, 316, 316L, 317L, 321,310S 309S, 410, 410S,420, 430, 431, 440A,904L |

| MOQ | 1tons.We also can accept sample order. |

| Shipment time | Within 15-20 workdays after receiving deposit or L/C |

| Export packing | Waterproof paper, and steel strip packed.Standard Export Seaworthy Package.Suit for all kinds of transport,or as required |

| Capacity | 2500 tons/year |

304 Stainless Steel Strip and Slit Coil

304 stainless steel strip and slit to width coil, ASTMA-666, is similar to Type 302, but has a maximum carbon content of 0.08%. This material has an excellent combination of corrosion resistance and formability. 304 is also known as 18/8 chrome-nickel, austenitic, stainless strip. It is a versatile alloy that welds well without filler. It’s commonly used in stampings and drawn parts. It’s non-magnetic in the annealed state and become magnetic with work hardening. Gibbs Interwire stocks Type 304 annealed stainless strip in gauges from 0.0053″ and 304 tempered strip in gauges from .0019”.

304 Stainless Steel Strip Chemical Composition

The chemical components of grade 304 stainless steel strip is summarized in the following table:

| Grade | Standard | C | Si | Mn | P | S | Cr | Ni | Mo |

| 304 | ASTM A240 | ≤0.07 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 18.00-20.00 | 8.00-11.00 | – |

304 Stainless Steel Strip Mechanical Properties

MECHANICAL PROPERTIES: (PER ASTM A240, A666)

| Type | Yield Strength 0.2% offset (KSI) | Tensile Strength (KSI) | % Elongation(2″ Gauge length) |

|---|---|---|---|

| 304 Ann | 30 min. | 75 min. | 40 min. |

| 304 ¼ Hard | 75 min. | 125 min. | 12 min. |

| 304 ½ Hard | 110 min. | 150 min. | 7 min. |

| 304L Ann | 25 min. | 70 min. | 40 min. |

| 304L ¼ Hard | 75 min. | 125 min. | 12 min. |

| 304L ½ Hard | 110 min. | 150 min. | 6 min. |

PROCESSING:

Types 304 and 304L cannot be hardened by thermal treatment. Annealing: Heat to 1850o F to 2050 o F and cool at sufficiently high rates through 1500oF to 800oF to avoid precipitation of chromium carbides. Stress Relief Annealing: Cold worked parts should be stress relieved at 750oF for ½ to 2 hours.

FORMING:

Annealed Types 304 and 304L can be fabricated by roll forming, deep drawing, bending and most other fabrication techniques. Due to the high work hardening rate of these materials, intermediate anneals maybe required to successfully fabricate the part.

WELDING:

Types 304 and 304L are weldable by most fusion or resistance welding techniques. If filler metal is required, Type 308 is normally used. Type 304L should be used in heavier sections to reduce the occurrence of carbide precipitation in the heat affected region adjacent to the weld pool

CORROSION:

Types 304 and 304L provides corrosion resistance in a wide range of moderately oxidizing and reducing conditions, fresh water and non-marine applications

What Are 304 Stainless Steel Strip Applications

Grade 304 stainless steel foils rolls are popular for a variety of commercial and industrial applications.

- Automotive

- Surgical instruments

- Architecture

- Heat treating

- Precision electronical parts

- Solar and alternative energy

- Other Precision Parts

![]()

![]()

![]()

![]()