-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

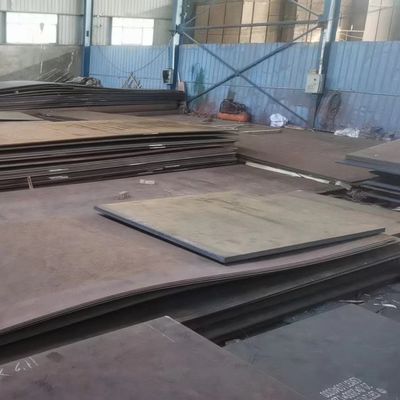

Abrasion-Resistant Steel AR400 AR450 AR500 AR600 Steel Plate 4.0 - 50.0mm Plate

| Place of Origin | China |

|---|---|

| Brand Name | BAOSTEEL BENSTEEL HBIS XINGCHENG |

| Certification | ISO |

| Model Number | AR400 AR450 AR500 AR600 |

| Minimum Order Quantity | 500 kgs |

| Price | 814 - 943 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

| Products | Wear Resistant Steel Plate | Thickness | 4.0 - 40.0mm |

|---|---|---|---|

| Width | 1000-2200mm | Length | 2000-12000mm |

| Standard | ASTM EN GB | Other Grade | AR400 / AR450 / AR500 / AR600 |

| Brand | BAOSTEEL XINYU XINGCHENG HBIS | Service | Cutting |

| Highlight | abrasion resistant steel plate,wear resistant steel plate,wear resistant plate |

||

Abrasion-Resistant Steel AR400 AR450 AR500 AR600 Steel Plate 4.0 - 50.0mm Plate

Products Specification of Wear Resistant Steel Plate

| Products Name | Abrasion Resistant Steel Plate |

| Thickness | 4.0 - 40.0mm |

| Width | 100 - 2200mm custom cutting any size as request |

| Length | 6m 8m 10m 11.5m 12m or cutting any length as request |

| Standard | ASTM JIS GB EN |

| MOQ | 500 Kgs |

| Deliver time | 7 - 14 days |

| Loading Port | Shanghai Port |

| Packing | wooden pallets |

| Other Grade | AR400 / AR450 / AR500 / AR600 NM400 NM450 NM500 NM600 |

| Service | Cutting, Heat treatment |

AR400 vs. AR450 vs. AR500 — Understanding Abrasion-Resistant Steel

In fabrication and construction, the composition and grade of the steel plate materials used have a tremendous effect on the end product. Abrasion-resistant steel plate is a normal steel plate that possesses a tougher, harder quality that lasts about four times longer when compared to a common high-strength structural steel plate.

What is Abrasion-Resistant Steel Plate?

Abrasion-resistant (AR) steel plate is a high-carbon alloy steel plate, which signifies that AR is formable and weather-resistant due to the added alloys, and harder due to the addition of carbon.

Carbon is added during the formation of steel plate which considerably increases hardness and toughness, but reduces strength. Hence, the AR plate is employed in conditions where wear and tear and abrasions are the main causes of failure. The AR plate is not perfect for structural construction applications, like support beams in buildings or bridges.

Common applications of the AR plate include dump liners, grates, buckets, construction attachments, conveyors, body armor, and ballistic plates (and as targets at shooting ranges).

How the Quenched and Tempered Process Creates AR Plate

AR material is created by quenching and tempering forged steel blocks, or ingots. At the time of this process, the grain structure is modified to increase toughness and promote formability (or, to be less brittle), which leads to through-hardening of the material.

Quenching and tempering (Q&T) is a two-part process:

Quenching occurs when steel is brought to a high temperature, normally between 1,500 and 1,650 °F and is quickly cooled with water. This process allows crystal structures to form within the steel, increasing hardness.

Tempering is the process of re-heating quenched steel to a below-critical temperature (approximately 300 — 700 °F), and then enabling the plate to cool in normal air temperatures.

The reheating of material disintegrates the crystal structures formed at the time of the quenching process, while the long cooling enables the crystal structures to reform — preserving most of the hardness and strength, but increasing the overall ductility.

What’s with the F?

Usually, abrasion-resistant steel is termed “AR450F” and “AR400F” (and at times “AR500F”). At present, the AR material with or without the “F” is interchangeable, but — traditionally — material with an “F” simply implied that it was "formable" and can possibly be bent to a certain degree without cracking.

When mills created both non-formable and formable steel plates, formable was somewhat costlier. Yet, more competitive pricing and reduced demand have resulted in the production of formable-only AR steel.

What is Through-Hardening?

AR steel is usually explained as being through-hardened, but what does that actually mean?

The composition of the whole plate changes when the grain structure changes during the primary heating stage of Q&T. This is known as through-hardening. Through-hardening is different from “case-hardening,” also known as “surface-hardening,” which only hardens the surface while enabling the metal deeper beneath to stay soft. In this case, the hardening or composition of the plate only varies at the surface level.

AR400 versus AR450 versus AR500+

Before this article dives into the difference between these common types of AR steel, it is significant to explain that AR steels are not controlled by a particular chemistry, but by a level of hardness.

A variety of mills may have different “recipes” for AR steel, but the produced material is subjected to a hardness test — called the Brinell Test — for determining the class in which it falls.

The Brinell Hardness Number (BHN) is the technical difference between AR400, AR450, and AR500. BHN signifies the hardness level of the material:

- AR400: 360-440 BHN Typically

- AR450: 430-480 BHN Typically

- AR500: 460-544 BHN Typically

- AR600: 570-625 BHN Typically (less common, but available)

![]()

![]()

![]()

![]()