-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

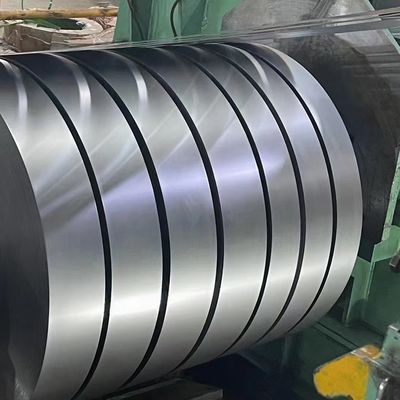

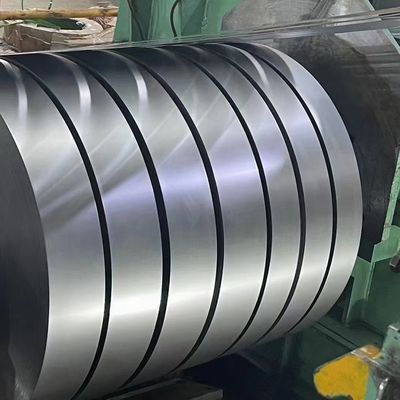

0.1mm 0.2mm 0.3mm 0.4mm 0.5mm Thickness 304 Stainless Steel Strip Bright Annealing Finishing

| Place of Origin | China |

|---|---|

| Brand Name | TISCO |

| Certification | ISO |

| Model Number | 200Series 300 Series 400 Series C276 904L,Monel 400 K500 |

| Minimum Order Quantity | 2 Ton |

| Price | 2400 - 3500 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

| Products | Stainless Steel Strip | Thickness | 0.1 - 3.0mm |

|---|---|---|---|

| Width | Within 1500mm | MOQ | 1000 Kgs |

| Grade | 200 Series 300 Series 400 Series , Nickel Alloy | Surface | BA 2B NO.4 HL 8K NO.1 |

| Standard | ASTM EN GB JIS | Packing | Wooden Frame And Water Proof Paper |

| Highlight | thin stainless steel strips,stainless strip,stainless steel metal strips |

||

0.1mm 0.2mm 0.3mm 0.4mm 0.5mm Thickness 304 Stainless Steel Strip Bright Annealing Finishing

| Product Name | 304 Stainless Steel Strip |

|---|---|

| Thickness | 0.1mm-3.0mm or as required |

| Width | 5-1500mm or as required |

| Length | As request |

| Standard | ASME, ASTM, EN, BS, GB, DIN, JIS, etc |

| Material | 201 |

| Surface | 2B, BA, 2D, 6K, 8K, NO.1, NO.4, HL, SB,or according to customer requirement |

| Packaging | Standard export sea-worthy packing |

| Technique | Hot rolled/Cold rolled |

| Delivery time | 7-15 Days |

| Application range | Foodstuff, gas, matallurgy, biology, electron, chemical, petroleum, boiler, nuclear energy,medical equipment, frillizer, etc |

| Note | The other specifications can be produced as per customers' requirements |

Size of our Stainless Steel Strip

| Grade | Thickness | Width |

| 304 | 0.1mm 0.2mm 0.3mm 0.4mm 0.5mm 0.6mm 0.7mm 0.8mm 1.0mm 1.2mm 1.5mm 2.0mm 2.5mm 3.0mm 4.0mm 5.0mm 6.0mm 8.0mm 10.0mm | 5 - 1500mm custom as request |

304 Stainless Steel Strip Chemical Composition

The chemical components of grade 304 stainless steel strip is summarized in the following table:

| Grade | Standard | C | Si | Mn | P | S | Cr | Ni | Mo |

| 304 | ASTM A240 | ≤0.07 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 18.00-20.00 | 8.00-11.00 | – |

304 Stainless Steel Strip Mechanical Property

Below The Table Is For Your Reference:

| Grade | EN Grade | Yield Strength Rp0.2 (N/mm²) |

Tensile Strength Rm (N/mm²) |

Hardness | Vickers Hardness (HV) |

Elongation A80 % Min. |

| 304 | 1.4301 | ≥205 | ≥520 | ANN | Max200 | ≥40 |

| ≥450 | ≥700 | 1/4 Hard | 220-250 | ≥20 | ||

| ≥700 | ≥850 | 1/2 Hard | 250-310 | ≥8 | ||

| ≥880 | ≥1000 | 3/4 Hard | 310-370 | ≥4 | ||

| ≥1020 | ≥1150 | Full Hard | ≥370 | ≥1 |

Surface Finishes for 304 Stainless Steel Strip

Stainless steel strip is used in many industries. Many manufacturers are in fact, utilizing surface finishes for 304 stainless steel strip to achieve different results. If you are unfamiliar with surface finishes for 304 stainless steel strip, then this guide is for you.

- BA (Bright Annealed):Sometimes specified as “Bright Annealed Stainless Steel”, is a bright, cold-rolled, reflective finish retained by final annealing in a controlled atmosphere furnace. It is highly reflective and has the same appearance as a mirror. A final light rolling pass through polished rolls produces a smooth, reflective surface, excellent for decorative applications.

- 2B Finish:Cold rolled, heat treated, pickled, pinch passed. The most common cold rolled mill finish. Dull grey slightly reflective finish. Can be used in this condition or frequently is the starting point for some polished finishes.

- 2D Finish:A dull finish that is produced by cold rolling followed by annealing and descaling. Used in deep drawn objects which are often polished after fabrication.

- Polishing Bright Finish:Mechanical Polishing: This process removes surface imperfections caused by grinding and other processing operations. In addition, it provides a moderate degree of luster to the surface which can be further enhanced by subsequent buffing operations using grease or oil emulsions with rouge or aluminum oxide compounds.

![]()

![]()

![]()

![]()