-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

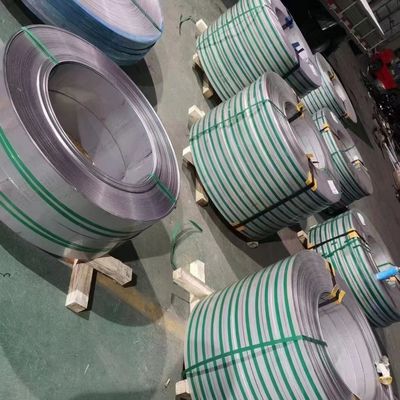

Cold Rolled / Hot Rolled 321 Stainless Steel Strips Thickness 0.1 - 12.0mm from POSCO TISCO

| Place of Origin | China |

|---|---|

| Brand Name | TISCO |

| Certification | ISO |

| Model Number | 200Series 300 Series 400 Series C276 904L,Monel 400 K500 |

| Minimum Order Quantity | 2 Ton |

| Price | 2400 - 3500 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products | Stainless Steel Strip | Thickness | 0.1 - 3.0mm |

|---|---|---|---|

| Width | Within 1500mm | MOQ | 1000 Kgs |

| Grade | 200 Series 300 Series 400 Series , Nickel Alloy | Surface | BA 2B NO.4 HL 8K NO.1 |

| Standard | ASTM EN GB JIS | Packing | Wooden Frame And Water Proof Paper |

| Highlight | thin stainless steel strips,stainless strip,stainless steel metal strips |

||

Cold Rolled / Hot Rolled 321 Stainless Steel Strips Thickness 0.1 - 12.0mm from POSCO TISCO

| Product Name | Cold Rolled ASTM 201 SS 304 304L 316 316L 317L 309s 310s 321 430 410 420 3cr12 Grade Stainless Steel Coil/Strip/Sheet |

| Length | as required |

| Width | 3mm-2000mm or as required |

| Thickness | 0.1mm-3mm or as required |

| Standard | AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc |

| Technique | Hot rolled / cold rolled |

| Surface Treatment | 2B or according to customer requirement |

| Thickness Tolerance | ±0.01mm |

| Material | 201, 202, 301, 302, 303, 304, 304L, 304H, 310S, 316, 316L, 317L, 321,310S 309S, 410, 410S,420, 430, 431, 440A,904L |

| Application | It is widely used in high temperature applications, medical devices, building materials, chemistry, food industry, agriculture, ship components. It also applies to food, beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, and screen. |

| MOQ | 1 ton , We can accept sample order. |

| Shipment Time | Within 15-20 workdays after receiving deposit or L/C |

| Export Packing | Waterproof paper, and steel strip packed. Standard Export Seaworthy Package.Suit for all kinds of transport,or as required |

| Capacity | 250,000 tons/year |

321 Stainless Steel Strip

321 stainless steel icontains a Titanium addition of at least five times the carbon content. This addition is made to reduce or eliminate chromium carbide precipitation - resulting from welding or exposure to high temperatures. Maximum stabilization is accomplished by annealing between 955° and 1010° C. AISI 321 has extensive use in aircraft parts, such as exhaust systems where operating temperatures are higher than 427° C. and where corrosive conditions are not too severe; also because of its resistance to scaling and vibration fatigue.

We are an expert manufacturer of extensive 321 SS strip ranges. We produce various widths and lengths options or specially cut according to your order. Our 321-grade stainless steel can be hardened through cold working.

TuoLian also supports 321 SS strip’s custom packaging. Request a quotation now, and we will wait for your order.

| Product Parameters: Stainless Steel coil | |||

| Width | 5mm~1500mm | ||

| Thickness | 0.2mm~20mm | Thickness tolerance | +/-0.02mm |

| Standard | ASTM/ASME 240/480,JIS 4305,DIN EN 10088-2 | ||

| Surface | 2B,BA,8K,NO.1,NO.4,NO.3,hairline,gold ,black ,rose gold,etc | ||

| specification | 1000,1219,1250,1500,1800,2000,2200 | ||

| Grade | 304 304DQ 201 301 304L 304H 309S 310S 316L 316TI 317L 321 347 347H 430 410 410S 420 420J2 430 430LNT 430J1L 434 436L 439 441 443 444 904L 2205 2507 S32750 S32760 445J2 442etc | ||

Chemical Composition

| Grade | C | Mn | Si | P | Sa | Cr | N | Ni | Ti |

| SS 321 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 – 19.00 | 0.10 max | 9.00 – 12.00 | 5(C+N) – 0.70 max |

Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1457 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Applications :

- Aircraft exhaust manifolds and flanges.

- Jet engine parts

- Aircraft exhaust manifolds and flanges

- Jet engine parts

- Chemical handling equipment

- Oil refinery equipment

- Firewalls

![]()

![]()

![]()

![]()