-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

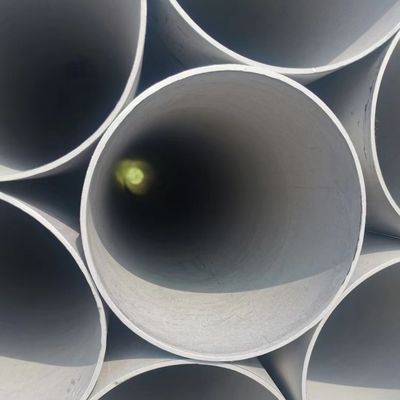

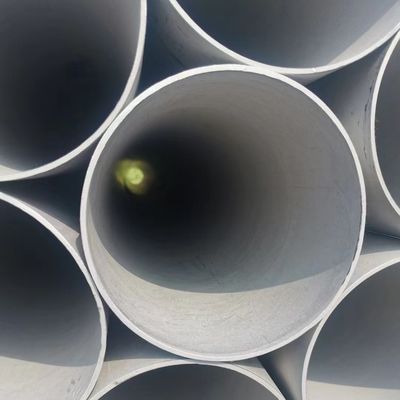

NO8020 Nickel Alloy Seamless Welded Pipe 20 DN10 -DN400 STD In 6m Length

| Products | Nickel Alloy Pipe | Grade | UNS NO8020 |

|---|---|---|---|

| Diameter | OD6 - 1020mm | Length | 6m Or Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Thickness | 0.5 - 40.0mm |

| Highlight | Nickel Alloy Seamless Welded Pipe,DN400 Nickel Alloy Pipe |

||

Nickel Alloy NO8020 Seamless Pipe / Welded Pipe Alloy 20 Pipe DN10 -DN400 STD in 6m Length

| Material | Monel/Inconel/Hastelloy/Duplex Steel/PH Steel/Nickel Alloy Pipe |

| Shape | Round,Forging,Ring,Coil,Flange,Disc,Foil,Spherical,Ribbon,Square,Bar,Pipe,Sheet |

|

Grade |

Duplex: 2205(UNS S31803/S32205),2507(UNS S32750),UNS S32760(Zeron 100),2304,904L |

| Others:253Ma,254SMo,654SMo,F50(UNSS32100)F60,F61,F65,1J22,N4,N6 etc | |

| Alloy : Alloy 20/28/31 | |

| Hastelloy:HastelloyB/ -2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N/g | |

|

Hastelloy B/UNS N10001, Hastelloy B-2/UNS N10665/DIN W. Nr. 2.4617, Hastelloy C, Hastelloy C-4/UNS N06455/DIN W. Nr. 2.4610, Hastelloy C22/UNS N06022/DIN W. Nr. 2.4602, Hastelloy C276/UNS N10276/DIN W. Nr. 2.4819, Hastelloy X/UNS N06002/DIN W. Nr. 2.4665 |

|

| Haynes: Haynes 230/556/188 | |

| Inconel 600/601/602CA/617/625/713/718/738/X-750,Carpenter 20 | |

|

Inconel 718 / UNS N07718 / DIN W. Nr. 2.4668,Inconel 601 / UNS N06601 / DIN W. Nr. 2.4851, Inconel 625 / UNS N06625 / DIN W. Nr. 2.4856,Inconel 725 / UNS N07725, Inconel X-750 / UNS N07750 / DIN W. Nr. 2.4669,Inconel 600 / UNS N06600 / DIN W. Nr. 2.4816 |

|

| Incoloy: Incoloy 800/800H/800HT/825/925/926; | |

| GH: GH2132,GH3030,GH3039,GH3128,GH4180,GH3044 | |

| Monel: Monel 400/K500/R405 | |

| Nitronic: Nitronic 40/50/60 | |

| Nimonic: Nimonic 75/80A/90/A263 | |

|

Specification |

Wire: 0.01-10mm Strip: 0.05*5.0-5.0*250mm Bar: φ4-50mm;Length 2000-5000mm Pipe: φ6-273mm;δ1-30mm;Length 1000-8000mm Sheet: δ 0.8-36mm;Width 650-2000mm;Length 800-4500mm |

| Standard | GB,AISI,ASTM,DIN,EN,SUS,UNS etc |

| Inspection | ISO,SGS,BV and so on. |

|

Application |

High temperature components such as turbine blades, guide vanes, turbine disks, high pressure compressor disks,machine manufacturing |

About UNS N08020 / Alloy 20 Materials

Alloy 20 (UNS N08020) is an austenitic, nickel-iron-chromium based super alloy with additions of Copper and Molybdenum which provide resistance to hostile environments, pitting, and crevice corrosion. It is also stabilized with Columbium to minimize carbide precipitation during welding. Alloy 20 appears to fall between both the stainless and nickel categories as it contains characteristics of both. It was designed for maximum resistance to acid attack and demonstrates superior resistance to stress-corrosion cracking in boiling 20% to 40% sulfuric acid, and also has excellent general corrosion resistance to sulfuric acid and to chloride stress corrosion cracking. Alloy 20 has good mechanical properties at both ambient and elevated temperatures, up to approximately

930°F (500°C) and is readily fabricated by usual industrial processes.

APPLICATIONS of uns n08020 nICKEL ALLOY PIPE

Alloy 20 was originally designed for use in sulfuric acid related applications; however, it is now frequently used in a wide variety of industries. Applications that commonly use Alloy 20 include:

- Chemical and allied industries

- Food and dye production

- Heat exchangers

- Explosives

- Tanks

- Valves

- Pickling racks

- Manufacture of synthetic rubber and plastics

- Pharmaceuticals

- SO2 scrubbers and other severe environments

GRADE SPECIFICATION:

- ASTM/ASME: UNS N08020

- EURONORM: FeMi35Cr20Cu4Mo2

- DIN: 2.4660

CORROSION RESISTANCE:

- Excellent resistance to general corrosion, pitting, and crevice corrosion in chemicals containing chlorides and sulfuric, phosphoric, and nitric acids.

- Nickel content aids in chloride ion stress and corrosion resistance.

- Additions of Copper and Molybdenum provide resistance to hostile environments, pitting, and crevice corrosion.

- Chromium adds to its resistance of oxidizing environments such as nitric acids.

- Columbium reduces the effects of carbide precipitation.

WELDABILITY:

- All commonly used welding methods, with the exception of oxyacetylene, can be successfully used.

- The presence of Columbium tends to minimize the precipitation of carbides in the heat-affected zone, so the material may be used in the as-welded condition in most cases.

- Pre-heating is not required.

HEAT TREATMENT:

- Cannot be hardened by heat treatment.

- Stabilized-annealing is done at 1750-1850°F, followed by water quenching.

- Stress relieving can be performed on annealed material up to 950°F.

PROCESSING – HOT FORMING:

- Heat uniformly to a starting temperature of 2100-2225°F. Finish forging before the stock drops below 1800°F.

- In order to stabilize the material after hot working operations, reheat at 1750-1850°F for a minimum of 1/2-hour per one inch of thickness and water quench.

PROCESSING – COLD FORMING:

- Alloy 20 has good cold formability. Bending, drawing and pressing, and other forming operations that occur in the production of fabricated items are readily performed.

- Alloy 20 can normally be press brake bent over a radius twice the materials thickness.

- After cold reductions of more than 15%, a final stabilizing annealing is often required.

MACHINABILITY:

- Because of Alloy 20′s high work-hardening rate the following are required:

- Only low surface-cutting speeds are possible compared with low-alloy standard austenitic stainless steel.

- Tools should be engaged at all times.

- Heavy feeds are important in getting below the work-hardened ‘skin’.

Chemical Properties of Alloy 20:

| TYPE | C | Cr | Cu | Fe | Mn | Mo | Ni | P | Si | S | Nb (Cb) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Alloy 20 UNS N08020 |

0.07 max |

min: 19.00 max: 21.00 |

min: 3.00 max: 4.00 |

Balance | 2.00 max |

min: 2.00 max: 3.00 |

min: 32.00 max: 38.00 |

0.045 max |

1.00 max |

0.035 max |

8 XC min 1.00 max |

Mechanical Properties of Alloy 20:

| Stabilized-Annealed Condition | ||||||

|---|---|---|---|---|---|---|

| Product Form | Tensile Strength, ksi (min) |

Yield Strength, 0.2% offset ksi (min) |

Elongation % (min) | Reduction of Area % (min) |

Hardness Brinell (max) |

Hardness Rockwell B (max) |

| Plate, Sheet | 80 | 35 | 30 | — | 217 | 95 |

| Bar | 80 | 35 | 30 | 50 | — | — |

![]()

![]()

![]()

![]()