-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

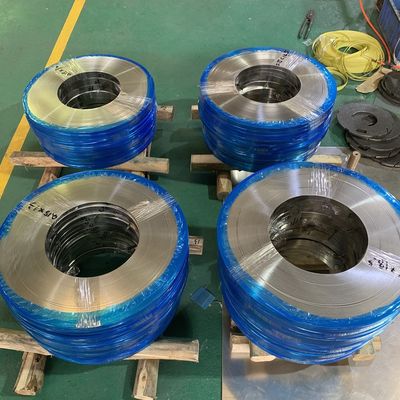

Monel 400 Alloy Strip Thickness 0.1 - 3.0mm in Width 5 - 1219mm Alloy 400 Strip Rolls

| Place of Origin | China |

|---|---|

| Brand Name | TISCO |

| Certification | ISO |

| Model Number | 200Series 300 Series 400 Series C276 904L,Monel 400 |

| Minimum Order Quantity | 2 Ton |

| Price | 2400 - 3500 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

| Products | Stainless Steel Strip | Thickness | 0.1 - 3.0mm |

|---|---|---|---|

| Width | Within 1500mm | MOQ | 200 Kgs |

| Grade | 200 Series 300 Series 400 Series , Nickel Alloy | Surface | BA 2B NO.4 HL 8K NO.1 |

| Standard | ASTM EN GB JIS | Packing | Wooden Frame And Water Proof Paper |

| Highlight | thin stainless steel strips,stainless strip,stainless steel metal strips |

||

Monel 400 Alloy Strip Thickness 0.1 - 3.0mm in Width 5 - 1219mm Alloy 400 Strip Rolls

| Material | Nickel Alloy 800H,825,600,625,690,718 Hastelloy Alloy C276,C22 ,C2000, B2, B3, G30,Monel 400 K500 |

| Standard | AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc |

| Technique | Hot rolled / Cold rolled |

| Thickness | 0.1mm-3.0mm or as required |

| Width | 5 - 1000mm as required |

| Type | Precisiion Strip |

| Surface Treatment | Bright annealiing , Cold Rolled 2B |

| Application | High temperature components such as turbine blades, guide vanes, turbine disks, high pressure compressor disks,machine manufacturing |

| MOQ | 1000KG |

| Delivery time | 10-15 days |

| Export Packing | Waterproof paper, and steel strip packed.Standard Export Seaworthy Package.Suit for all kinds of transport,or as required |

Monel 400 Alloy Strip

Applicable Specifications

Strip and Foil: AMS 4544, ASME SB-127, ASTM B127, QQ-N-281

Description of Monel 400

Monel® 400 is a Nickel-Copper alloy with high strength and toughness and remains ductile even at subzero temperatures. Age-hardening treatments are not required to obtain the high strength properties of Monel® 400 because it is a solid-solution alloy that is hardened only through cold working. The alloy is resistant to corrosion in many reducing environments, offering excellent corrosion resistance in seawater, hydrofluoric acid, sulfuric acid, and hydrochloric acid. Monel® 400 also shows resistance to stress corrosion cracking and pitting in fresh water, is resistant to oxidization and can operate from cryogenic temperatures to 500°F (260°C).

Monel 400 Available Formats

Magellan Metals offers Monel 400® in a variety of forms, including:- Pipe & Welded pipe

- Pipe fittings

- Seamless tube & Welded tube

- Flanges

- Bar

- Sheet

- Wire

- Plate

- Forgings

- Strip Coil

Monel 400 Applications

Monel 400 has many different industrial applications, some of which include:- Industrial heat exchangers

- Boiler feed water heaters

- Chlorinated solvents

- Marine engineering

- Gasoline & freshwater tanks

- Chemical & hydrocarbon processing equipment

Nominal Composition

C: 0.03 max

Mn: 2.00 max

Si: 0.5 max

S: 0.024 max

Cu: 28.0 – 34.0

Ni: 63.0 – 70.0

Fe: 2.5 max

Physical Properties

Density: 0.318 lb/in3, (8.8 g/cm3)

Modulus of Elasticity (E):

At 70°F (20°C): 26.0 x 103 ksi (179 GPa)

Modulus of Rigidity (G)

At 70°F (20°C): 9.5 x 103 ksi (65.5 GPa)

Coefficient of Expansion:

8.8 microinches/in-oF (70-600oF)

15.7 µm/m-°C (20-300°C)

Electrical Resistivity: 20.1 µohm-in, (51.1 µohm-cm)

Thermal Conductivity:

151 Btu-in/ft2hr-°F

21.8 W/m-K

Applicable Specifications

Strip and Foil: AMS 4544, ASME SB-127, ASTM B127, QQ-N-281

Typical Mechanical Properties

- Annealed

- Heat Treatment: 1600-1800°F (870-980°C)

- Tensile Strength: 70 – 85 ksi (480-585 MPa)

- Suggested Operating Conditions: -300°F to 500°F (-184°C to 260°C)

- Spring Temper

- Heat Treatment: (Stress relieve as needed)

- Tensile Strength: 120 ksi

- Suggested Operating Conditions: -300°F to 500°F (-184°C to 260°C)

![]()

![]()

![]()

![]()