-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

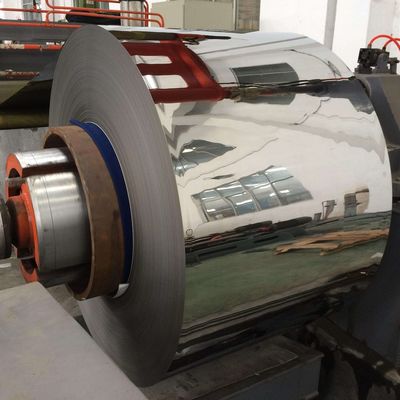

UNS N10276 Nickel Alloy Stainless Steel Strip Hastelloy C276 Strips Bright Annealing Finishing

| Place of Origin | China |

|---|---|

| Brand Name | TISCO |

| Certification | ISO |

| Model Number | 201 202 301 304 316L 321 310S 410 430 440C C276 904L |

| Minimum Order Quantity | 2 Ton |

| Price | 2400 - 3500 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

| Products | Stainless Steel Strip | Thickness | 0.1 - 3.0mm |

|---|---|---|---|

| Width | Within 1500mm | MOQ | 200 Kgs |

| Grade | 200 Series 300 Series 400 Series , Nickel Alloy | Surface | BA 2B NO.4 HL 8K NO.1 |

| Standard | ASTM EN GB JIS | Packing | Wooden Frame And Water Proof Paper |

| Highlight | thin stainless steel strips,stainless strip,stainless steel metal strips |

||

UNS N10276 Nickel Alloy Stainless Steel Strip Hastelloy C276 Strips Bright Annealing Finishing

| Place of Origin: China (Mainland) | Brand Name: DELTA | Model Number: Hastelloy C276 | Application: oil,gas,turbine,chemistry,aerosapce |

| Shape: coil | Material: Hastelloy C276 alloy (Ni-Cr--Mo alloy) | Dimensions: Thickness:0.1~3mm;width:3 - 1219mmmm | Chemical Composition: Ni:Bal;Cr:14.5~16.5;Mo:15~17 |

| Process method: cold rolling/cold rolled |

Surface Finishing: Bright Annealing |

Loading Port: Shanghai Port | Packing: waterproof strips |

| Product Name | Stainless Steel Strips / Nickel Alloy Strips |

| Length | As required |

| Width | 3mm-1219mm or as required |

| Thickness | 0.1mm-3.0mm or as required |

| Standard | AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc. |

| Technique | Hot rolled / cold rolled |

| Surface Treatment | 2B or according to customer requirement |

| Thickness tolerance | ±0.01mm |

| Material | 201, 202, 301, 302, 303, 304, 304L, 304H, 310S, 316, 316L, 317L, 321,310S 309S, 409L ,410, 410S,420, 430, 431, 440A,904L,Monel 400 C276 C22 |

| Application | It is widely used in high temperature applications, medical devices, building materials, chemistry, food industry, agriculture, ship components.It also applies to food, beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, and screen. |

| MOQ | 1tons.We also can accept sample order. |

| Shipment time | Within 15-20 workdays after receiving deposit or L/C |

| Export packing | Waterproof paper, and steel strip packed.Standard Export Seaworthy Package.Suit for all kinds of transport,or as required |

| Capacity | 250,000 tons/year |

Hastelloy c276 alloy suit for many kinds of chemical process industry which contain oxidizing medium and reductant. High molydenum and chromimum content make it can resist the chloride corrosin, and tungsten make it corrosion resistance better. C276 is one of a few material that can resist the corrosion of most chlorine, hypochlority and chlorine dioxide, this alloy have prominent corrosion resistance to high concentration chlorate(iron chloride and copper chloride)

We can produce Hastelloy plate according toASME, AMS, DIN, GB etc.

- Standards: ASME SB-575

- Density: 8.94g/cm3

- Size: 0.1mm~3.0mm(thickness)*10mm~1219mm(width)*coil

- Each coil weight is about 30~50KGS

- Annual export quantity: 100tons

Keywords:Hastelloy C276 strip,Hastelloy C276 sheet,C276 strip,0.1mm Hastelloy strip,UNS N10276 strip,thinner Hastelloy strip,

0.2mm Hastelloy C276 strip,0.3mm Hastelloy C276 strip,Hastelloy C276 coil,0.5mm Hastelloy C276 coil,0.4mm Hastelloy C276 strip,China Hastelloy C276 strip coil

| Chemical analysis of alloy C276 | |||||||||||

| C | MN | P | S | Si | Cr | Ni | Mo | Co | Fe | W | V |

| 0 .01 max | 1.00 max | 0.04 max | 0.03 max | 0.08 max | 14.5 -16.5 | rem | 15.0 - 17.0 | 2.5 max | 4.0 – 7.0 |

3.0 - 4.5 | 0.35 |

| Mechanical Properities(Under Room Temperature) | |||||||||||

| Yield Strength,min,(Mpa) | Tensile Strength,min,(Mpa) | Elongation,min,(%) | |||||||||

| 283 | 690 | 40 | |||||||||

| Packaging Detail:in plasic sheets and in wooden cases |

| Delivery Detail:40 days |

![]()

![]()

![]()

![]()