-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

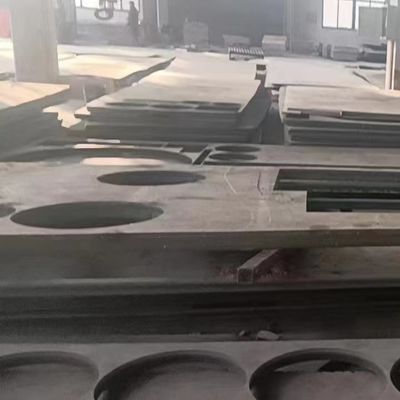

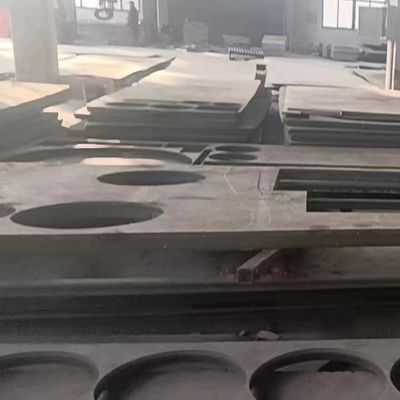

TISCO Forged Stainless Steel Plate Thickness 10mm Grade 201 304 316L 310S 410 420 431 630

| Place of Origin | China |

|---|---|

| Brand Name | TISCO |

| Certification | ISO |

| Model Number | 201 304 316l 310s 321 410 420 431 630.etc |

| Minimum Order Quantity | 1 Ton |

| Price | 2500-3500 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 10Ton per week |

| Products Name | Stainless Steel Plate | Grade | 201 304 316l 310s 321 410 420 431 630.etc |

|---|---|---|---|

| Thickness | 10 - 300mm | Standard | ASTM EN GB |

| Width | Custom Cutting As Request | Surface | Black |

| Brand | TISCO BAOSTEEL | MOQ | 1 Ton |

| Highlight | TISCO Forged Stainless Steel Plate,10mm Stainless Steel Forged Plate,410 Stainless Steel Forged Plate |

||

Forged Stainless Steel Plate Thickness 10 - 300mm Grade 201 304 316L 310S 410 420 431 630

| Item | forged Stainless Steel Plate |

| Raw Material | Stainless steel |

| Grades | 201, 304, 304L, 310S, 309S, 316, 316L, 321, 409L, 410, 410S, 420, 430, 431,904L, 2205 ,2507,254SMO,253MA,17-4ph.etc. |

| Thickness | 10-300mm |

| Service | Cutting, polishing |

| Width | 1000mm 1219mm 1500mm or cutting any size as your request |

| Finish | 2B, BA, No. 1, No. 4, mirror, brush, hairline, chequered, embossed, etc. |

| Package | Standard export package |

WHY INDUSTRIES USE STAINLESS STEEL FORGINGS

Stainless steel has virtually limitless uses within a number of industries. To the layman, stainless steel is most often seen in the kitchen in sinks, stovetops, and flatware. The below industrial uses show its true versatility:

- Can withstand frequent cleaning or sanitizing, such as medical devices, food service equipment and processing equipment

- High corrosion resistance allows for prolonged exposure to corrosive environments such as pumps, valves, chemical and petrochemical processing equipment, and marine equipment

- Stainless Steel has high heat resistance in situations where it is used for heat exchangers, furnaces and ovens

- High performance in high wear and high stress environments, such as landing gears, motor components, fittings and connectors

- Using its high strength and stability in finished products such as frames, shafts/structural components and fittings

Available Grade of our Stainless Steel Forged Plate

| Series | Grade |

| 200Series | 201 |

| 300 Series | 304 304L 309S 310S 316L 317L 321 347 |

| 400 Series | 409L 410 420 431 440A/B/C |

| Duplex | 2205 2507 |

| Others | 904L 254SMO 253MA |

Regular Thickness of our Plate we can produce

| Thickness | 10.0mm 12.0mm 14.0mm 16.0mm 20.0mm 25mm 30mm 35mm 40mm 45mm 50mm 55mm 60mm 65mm 70mm 75mm 80mm 90mm 100mm 110mm 115mm 120mm 130mm 140mm 150mm 160mm 170mm 180mm 190mm 200mm 210mm 220mm 240mm 250mm 300mm |

Type of our foreged stainless steel products

| Type | Plate |

| Rod | |

| Pipe | |

| Circle |

Custom Stainless Steel Forging Advantages

The forging stainless steel process provides a wide range of benefits for your forged part project requirement needs. Great Lakes Forge creates custom stainless steel forging parts with the following benefits:

- Protective Oxide Layer - Stainless steel open die forgings contain a protective oxide layer that enhances corrosion resistance. These metal forgings resist stress cracking, crevice corrosion, pitting, deformation, and other hazards that could shorten the life span of a forged part.

- High Corrosion Resistance – Custom stainless steel forgings allow prolonged exposure to corrosive environments such as pumps, valves, chemical and petrochemical processing equipment, and marine equipment.

- High Heat Resistance - Stainless steel forged parts maintain incredibly high heat resistance qualities in situations used for heat exchangers, furnaces, and ovens.

In addition, stainless steel forgings retain all of the advantages of a forged part - the open die forging process contains the internal grain of the stainless steel, which creates a much more substantial part than a cast or machined part.

There are also certain disadvantages associated with using stainless steel as your material of choice for your forging needs. Some disadvantages associated with stainless steel are its high cost, fabrication handling ability, difficulty in welding, and finishing challenges.

![]()

![]()

![]()

![]()