-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

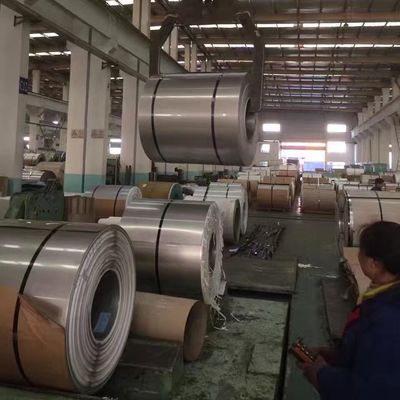

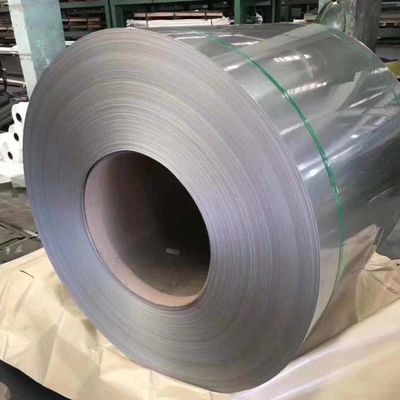

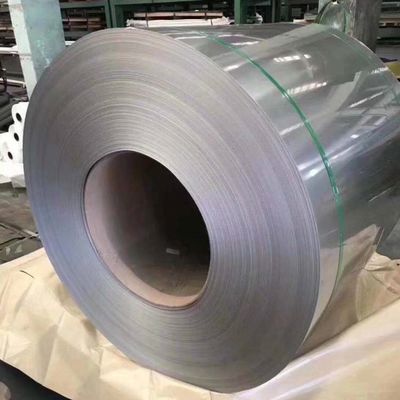

2B BA Surface Coil Stainless 410 410S Cold Rolled 0.3-2.5mm

| Place of Origin | China |

|---|---|

| Brand Name | TISCO BAOSTEEL POSCO |

| Certification | ISO |

| Model Number | 201 304 309S 310S 316L 317L 321 347 410 420 430.etc |

| Minimum Order Quantity | 2 Ton |

| Price | 2400 - 3500 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products | Stainless Steel Coil | Material | Stainless Steel |

|---|---|---|---|

| Thickness | 0.1 - 16.0mm | Width | 1000mm 1219mm 1500mm |

| Surface | 2B NO.1 NO.4 8K | Grade | 201 304 309S 310S 316L 317L 321 347 410 420 430 436 439 441 444.etc |

| Standard | ASTM EN GB JIS | Service | Cutting |

| Highlight | BA Surface coil stainless,2B coil stainless,410S ss sheet coil |

||

2B BA Surface 410/410S Stainless Steel Coil Cold Rolled 0.3 - 2.5mm SS Coils

410S Stainless Steel Coil

410S stainless steel coil, also called UNS S41008 martensitic steel coil.

410S stainless steel coils have good wear resistance with good formability and good weldability, it can be used as ultra-high strength material.

The rust resistance, corrosion resistance and weldability of 410s are better than 400 series of 420J2 stainless steel coil, which are used for parts with high toughness and impact load, such as automobile turbine blades, structural frames, linings, bolts, nuts, etc.

410S Stainless Steel Coil Specifications

| Product Name | 410S stainless steel coil |

| Grades | 410S/UNS S41008 |

| Hardness | Soft, Hard, Half Hard, Quarter Hard, Spring Hard as customer’s requirements |

| Thickness | 0.02mm-6.0mm |

| Width | 1.0mm-1500mm |

| Edge | Slit/Mill |

| Quantity Tolerance | ±10% |

| Paper Core Internal Diameter | Ø500mm paper core, special internal diameter core and without paper core on customer request |

| Surface Finish | NO.1/2B/2D/BA/HL/Brushed/6K/8K Mirror,etc |

| Packaging | Wooden Pallet/Wooden Case |

| Payment Terms | 30% TT deposit and 70% balance before shipment, 100% LC at sight |

| Delivery Time | 5-7 working days |

| MOQ | 200Kgs |

| Shipping Port | Shanghai/Ningbo port |

| Sample | The sample of 410S stainless steel coil is available |

410S Stainless Steel Coil Chemical Compositions

The chemical components of grade 410s stainless steel coil is summarized in the following table:

| Grade | C (max) | Si (max) | Mn | Cr | Ni | P(max) | S (max) | N (max) | Other Elements |

| 410S | 0.08 | 1 | 1.00 max | 11.50–13.50 | 0.20-0.55 | 0.04 | 0.03 | 0.06 | – |

410S Stainless Steel Coil Mechanical Properties

The mechanical properties of grade 410s stainless steel coil is summarized in the following table:

| Grade | Tensile Strength (MPa) min | Elongation (% in 50mm) min | Yield Strength 0.2% Proof (MPa) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 410S | 444 | 33 | 290 | 75 | 65 |

410s Mechanical Property :

- Tensile strength : > 415 Mpa

- Yield Strength : >205 Mpa

- Elongation (%): > 22%

- Hardness: < HRB89

- Bending Angle: 180 degree

Description About 410 410s Stainless Steel

410 (13Cr) has good corrosion resistance and mechanical processing performance. It is general-purpose steel and cutting tool steel. 410S is a steel grade that improves the corrosion resistance and formability of 410 steel. 410F2 is lead-free steel that does not degrade the corrosion resistance of 410 steel. 410J1 is a high-strength steel grade that further improves the corrosion resistance of 410 grade stainless steel, used for turbine blades and high-temperature parts.

The Advantages of 410 410s Cold Rolled Stainless Steel

High thermal conductivity, small expansion coefficient, good oxidation resistance, excellent resistance to stress corrosion, etc. The application of external refining technology (AOD or VOD) can greatly reduce the gap elements such as carbon and nitrogen.

The Application of 410 410s Stainless Steel

It is mostly used to manufacture parts that are resistant to atmospheric, steam, water, and oxidizing acids.

construction field; shipbuilding industry; petroleum and chemical industries; war and electricity industries; food processing and medical industry; boiler heat exchanger; machinery and hardware industry, etc.

![]()

![]()

![]()

![]()