-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

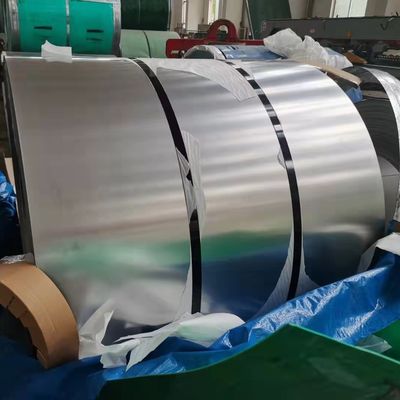

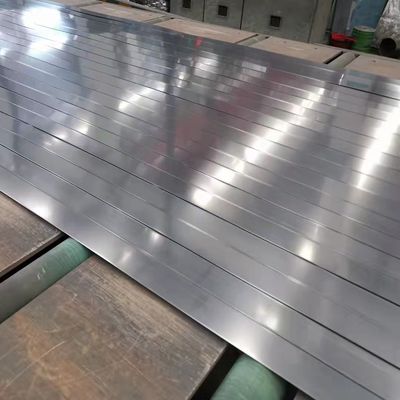

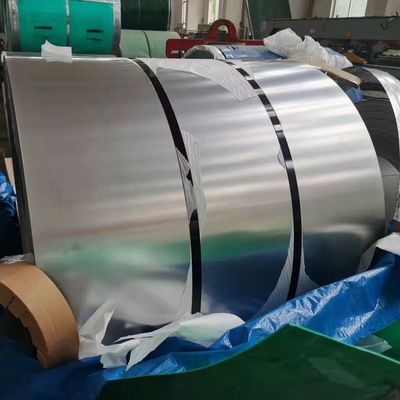

Heat Resistant 309S Stainless Metal Strips AISI EN 1.4833

| Place of Origin | China |

|---|---|

| Brand Name | TISCO |

| Certification | ISO |

| Model Number | 201 202 301 304 316L 321 310S 410 430 440C |

| Minimum Order Quantity | 2 Ton |

| Price | 2400 - 3500 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

| Products | Stainless Steel Strip | Thickness | 0.1 - 10.0mm |

|---|---|---|---|

| Width | Within 1500mm | MOQ | 2 Ton |

| Grade | 200 Series 300 Series 300 Series | Surface | BA 2B NO.4 HL 8K NO.1 |

| Standard | ASTM EN GB JIS | Packing | Wooden Frame And Water Proof Paper |

| Highlight | Heat Resistant stainless metal strips,309S stainless metal strips,EN 1.4833 stainless strip |

||

Heat Resistant 309S Stainless Steel Strip AISI309S Stainless Steel Roll EN 1.4833 Stainless Steel

309S Stainless Steel Strip Specifications

- Grade: 309S

- Standard: ASTM/EN/JIS

- Thickness: 0.03mm-3.0 mm

- Width: 1.5mm-600 mm

- Length: coil type or it can be produced as customer requirements

- Surface Finish: NO.1, 2B, 2H(Rerolled Bright), BA, No.4, 8K (Mirror), HL (Hairline), Polishing Bright, etc

- Edge: Mill Edge, Slit Edge, Deburred Edge, Round Edge, V Type Edge

Description of 309S Stainless Steel Strip

Types 309 Stainless Steel and 309S are austenitic chromium-nickel stainless steels that provide excellent corrosion resistance and heat resistance plus good strength at room and elevated temperatures. Type 309S Stainless Steel is identical to Type 309 except for a lower carbon content that minimizes carbide precipitation and improves weldability. They are essentially nonmagnetic as annealed and become lightly magnetic when cold worked.

PRODUCT FORMS:

Sheet, Strip

SPECIFICATIONS:

ASTM A167 (309), ASTM A240 (309S)

TYPICAL APPLICATIONS of 309S Stainless Steel Strip

furnace parts, heating elements, aircraft and jet engine parts, heat exchangers, sulfite liquor handling equipment, kiln liners, boiler baffles, refinery and chemical processing equipment, and auto exhaust parts

CHEMICAL COMPOSITION: (A167, A240)

| Element | Type 309 |

Type 309S |

|---|---|---|

| Carbon | 0.20 max. | 0.08 max. |

| Manganese | 2.00 max. | 2.00 max. |

| Sulfur | 0.030 max. | 0.030 max. |

| Phosphorus | 0.045 max. | 0.045 max. |

| Silicon | 0.75 max. | 0.75 max. |

| Chromium | 22.0 – 24.0 | 22.0 – 24.0 |

| Nickel | 12.0 – 15.0 | 12.0 – 15.0 |

MECHANICAL PROPERTIES: (ASTM A167, A240)

| Type | Yield Strength 0.2% offset (KSI) | Tensile Strength (KSI) | % Elongation (2″ Gauge length) |

|---|---|---|---|

| 309 | 30 min. | 75 min. | 40 min. |

| 309S | 30 min. | 75 min. | 40 min. |

PHYSICAL PROPERTIES:

| Density (lb./ in^2) @ RT | 0.29 | |

|---|---|---|

| Modulus of Elasticity in Tension (psi x 10^6) | 29.0 | |

| Specific Heat (BTU/o F/lb.) | 32 to 212 oF | 0.12 |

| Thermal Conductivity (BTU/hr/ft^2/ft) | 212oF | 9.0 |

| 932oF | 10.8 | |

| Mean Coefficient of Thermal Expansion (in. x 10^-6 per o F) | 32 to 212oF | 8.3 |

| 32 to 600oF | 9.3 | |

| 32 to 1,000oF | 9.6 | |

| 32 to 1,200oF | 10.0 | |

| Electrical Resistivity (micro ohms – cm) | at 70oF | 39.8 |

| Melting Point Range (oF) | 2550 – 2650 | |

| Oxidation Resistance – Continuous Service(oF) | 2000 | |

| Oxidation Resistance – Intermittent Service(oF) | 1800 |

PROCESSING:

These alloys are not hardenable by heat treatment. Anneal at 1900 – 2050°F (1038 – 1121°C), then water quench or rapidly air cool.

FORMING:

Types 309 and 309S Stainless Steels can be roll formed, stamped and drawn readily. In-process annealing is usually required to reduce hardness and increase ductility.

WELDING:

Type 309 is generally considered to have weldability nearly equivalent to the most common alloys of this class, Types 304 and 304L. When a weld filler is needed, AWS E/ER 309 and 310 are most often specified.

CORROSION:

Types 309 and 309S provide excellent general corrosion resistance. They are more resistant to marine atmospheres than Type 304. They exhibit high resistance to sulfite liquors and are useful for handling nitric acid, nitric-sulfuric acid mixtures, and acetic, citric, and lactic acids.

![]()

![]()

![]()

![]()